Intelligent Data Acquisition: A Look at FOCAS2 and Machine Tools

ELK GROVE VILLAGE, IL, September 19, 2023 -

Data acquisition and machine maintenance are now more than just operational requirements; they are strategic imperatives for manufacturing success.

Recognizing the critical role data plays, manufacturers are increasingly looking toward intelligent machine solutions that automate tasks and offer powerful data analytics capabilities to optimize performance. Shibaura Machine's machine tools integrated with FANUC's FOCAS2 allow machinists these capabilities while setting new standards for modern machine tool maintenance.

Understanding the Architecture: What is FANUC FOCAS2?

For those familiar with FANUC’s Computerized Numerical Control (CNC) systems, FOCAS2 isn't just another acronym; it's a framework for operational intelligence. FOCAS2, or Factory Automation Company Advanced Server, is more than a communication protocol—it's the information hub that connects your machine's intricate details securely to management teams. Embedded within FANUC CNCs like those found on Shibaura Machine’s machine tools, FOCAS2 library files bridge the gap between raw machine data and actionable insights.

FOCAS2 isn't just an update on existing options. Its enhanced compatibility includes support for modern PC operating systems and an even wider variety of CNC types. FOCAS2 also provides a seamless integration with IIoT Industry 4.0 tools, like Shibaura Machine's machiNetcloud. This allows the machine tools raw data to be transformed into refined, actionable operation applications.

A Winning Combination for Modern Machine Tool Maintenance

Pairing FOCAS2 with Shibaura Machine machine tools isn’t just about compatibility; it creates a dynamic partnership between hardware and software. The FANUC control systems are known for their high-speed, high-precision capabilities, which align perfectly with machine tools. FOCAS2 upgrades these machines into intelligent resources.

Below are several examples of how machinists can leverage the real-time, data-driven insights to inform maintenance schedules and optimize operational parameters.

Real-time Insights

With FOCAS2, you're not just operating a machine; you're gaining real-time data, from spindle speed to tool integrity. This immediacy facilitates agile responses to machine conditions, significantly reducing unscheduled downtime.

Enhanced Productivity

What makes a good machinist great is the ability to continually refine operations for maximum efficiency. With FOCAS2’s data-driven insights, fine-tuning becomes a science rather than an art, boosting productivity to new heights.

Beyond Hardware: Streamline Maintenance with FOCAS2

Shibaura Machine's machine tools equipped with FANUC controls and FOCAS2 provide an integrated solution designed for streamlined data analytics.

Invest in intelligent solutions with Shibaura Machine.

Related Articles View All Machine Tools Articles

Where Innovation Meets Expertise: Shibaura Machine and Manske Machinery, Inc. at WIMTS 2023

ELK GROVE VILLAGE, IL, September 6, 2023 - Shibaura Machine is excited to announce the company's participation at the 2023 Wisconsin Manufacturing & Technology Show (WIMTS), the largest manufacturing event in the state. With a history spanning over 30 year...

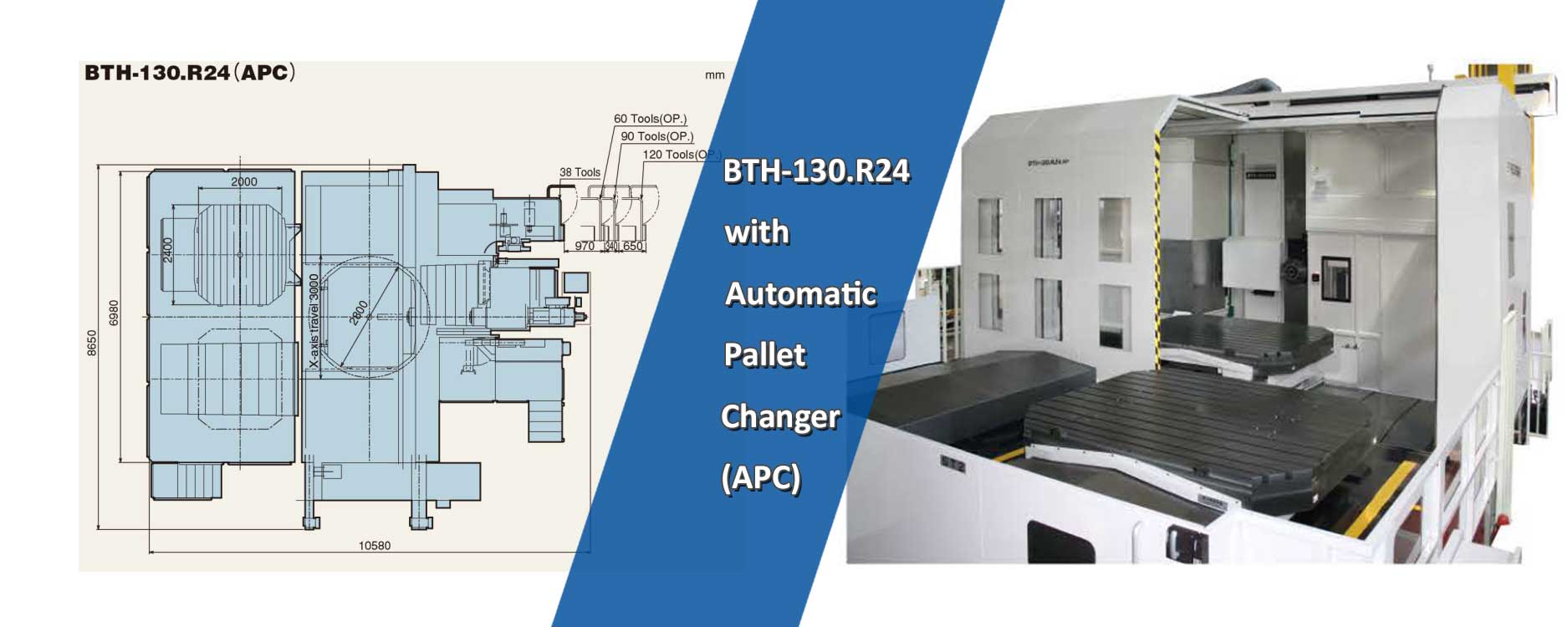

Read moreUnleashing Production Potential with Multi-Pallet Integration in BTH-Series Horizontal Boring Machines

ELK GROVE VILLAGE, IL, August 29, 2023 - In modern manufacturing, efficiency and adaptability are not just buzzwords; they're a cornerstone of success. As factories expand production mix and volume, new opportunities bring fresh challenges. A particular pa...

Read more5 Value Adds to Increasing Automation with the Multi-Pallet Magazine on the TMD Series

ELK GROVE VILLAGE, IL, August 22, 2023 - In manufacturing, staying ahead requires more than just meeting current demands – it requires a proactive anticipation of tomorrow's challenges. As the drive towards automation gains momentum, manufacturers are real...

Read moreEmbracing the Future: Shibaura Machine's Product Innovation in Multi-Tasking Equipment

ELK GROVE VILLAGE, IL, August 8, 2023 - As manufacturers seek to optimize efficiency and expand capabilities, multi-tasking machining centers have emerged as major innovations in the industry. These advanced machines integrate various machining operations ...

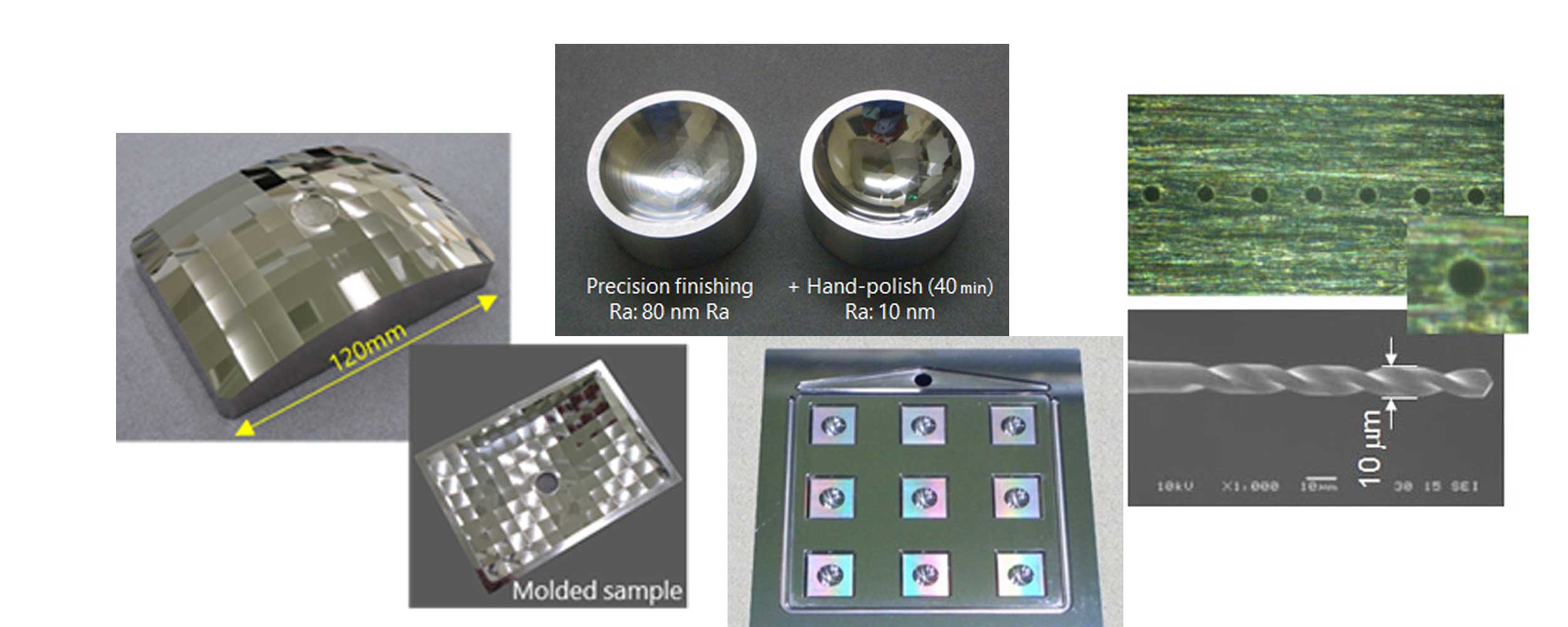

Read moreNano Machines Answer the Demand for High Precision Industrial Equipment Parts Production

ELK GROVE VILLAGE, IL, July 26, 2023 - In the world of industrial equipment manufacturing the importance of product quality cannot be overstated. While parts can vary widely depending on the specific industry and application, the overall quality influences...

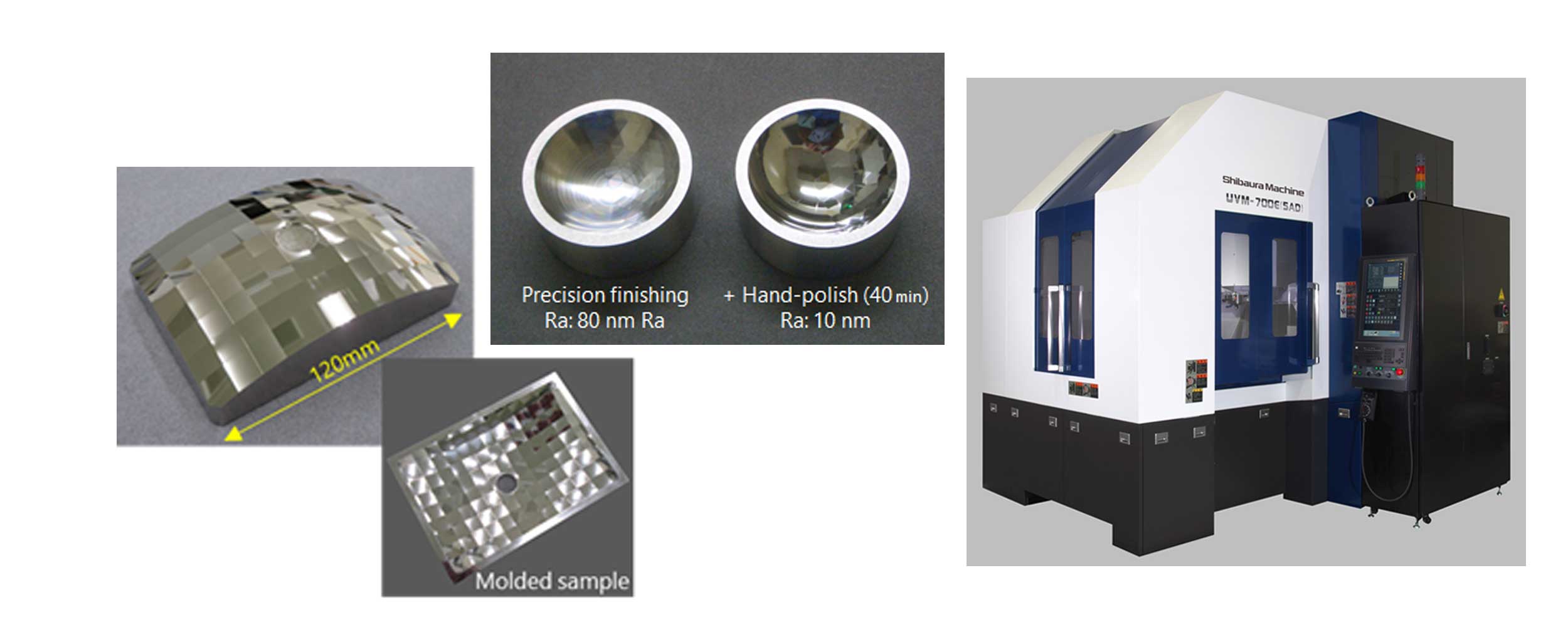

Read moreEnabling High Precision Machining with the UVM Series Nano Machines

ELK GROVE VILLAGE, IL, July 19, 2023 - Manufacturers continually seek innovative solutions to satisfy customer demands as industries increasingly require greater levels of precision, reliability, and complexity with their applications. Many are turning to ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools