Nano Machines Answer the Demand for High Precision Industrial Equipment Parts Production

ELK GROVE VILLAGE, IL, July 26, 2023 -

In the world of industrial equipment manufacturing the importance of product quality cannot be overstated. While parts can vary widely depending on the specific industry and application, the overall quality influences safety, compliance, cost-effectiveness, customer satisfaction, and brand reputation.

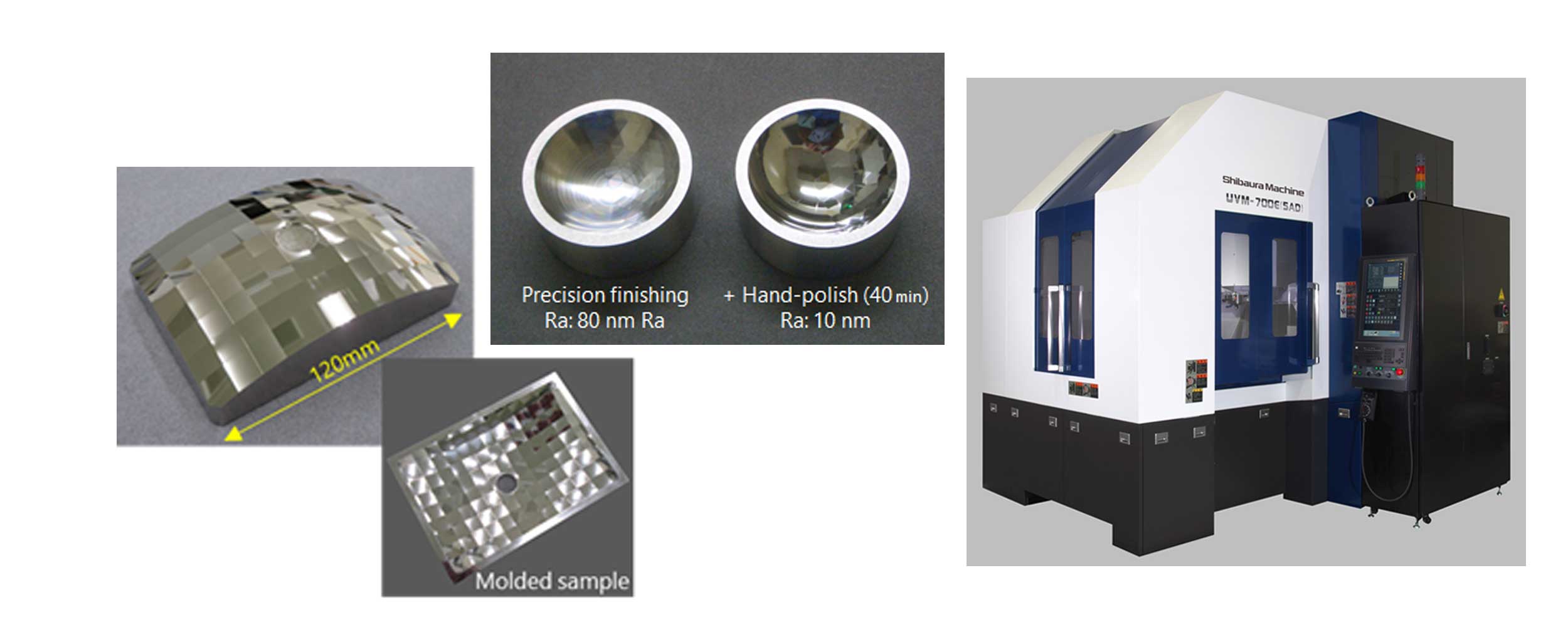

As the demand for high-quality parts in this sector grows, manufacturers continue to seek innovative solutions to meet customer requirements. Shibaura Machine's UVM series nano machine, with its high precision and micromachining capabilities, aligns perfectly with evolving market needs.

The Importance of Industrial Equipment Parts

Industrial equipment serves as the backbone of numerous industries, powering essential processes and driving advancements. From the production of vehicles and aircraft to the manufacturing of optical lens and electronic devices, industrial parts are at the heart of various sectors. Their significance and growing demand is attributed to several key factors:

1. Technological Advancements

As technology evolves, industries continuously introduce updated and advanced features, safety standards, and design elements to their products. For example, in the aerospace industry, advancements in jet engine technology require precision-engineered turbine blades and aerospace fuel cell components to improve fuel efficiency and reduce emissions. This necessitates the production of parts that meet these continually changing requirements.

2. Consumer Expectations

Expectations of quality and performance are higher than ever before. For example, in industries like automotive, where passenger safety is of the utmost importance, manufacturers must ensure that every component meets rigorous quality standards. Consumers expect durable, affordable, reliable, and visually appealing parts that enhance their overall experience and provide optimal functionality.

3. Regulatory Compliance

Industries like automotive and aerospace are subject to strict regulations and safety standards. Manufacturers must comply with these regulations to ensure product quality and safety. This includes using high-quality parts that meet specific criteria and performance benchmarks.

4. Global Market Expansion

Manufacturers cater to domestic demands and supply parts to a rapidly growing international market. For instance, in the fast growing virtual reality (VR) market, manufacturers must ensure every lens meets stringent global standards for clarity, focus, and distortion-free visuals. To successfully expand market presence, these manufacturers must be able to comply with international optical and safety standards in order to cater to the diverse needs of users around the world.

Nano Machine Technology Rises to the Challenge

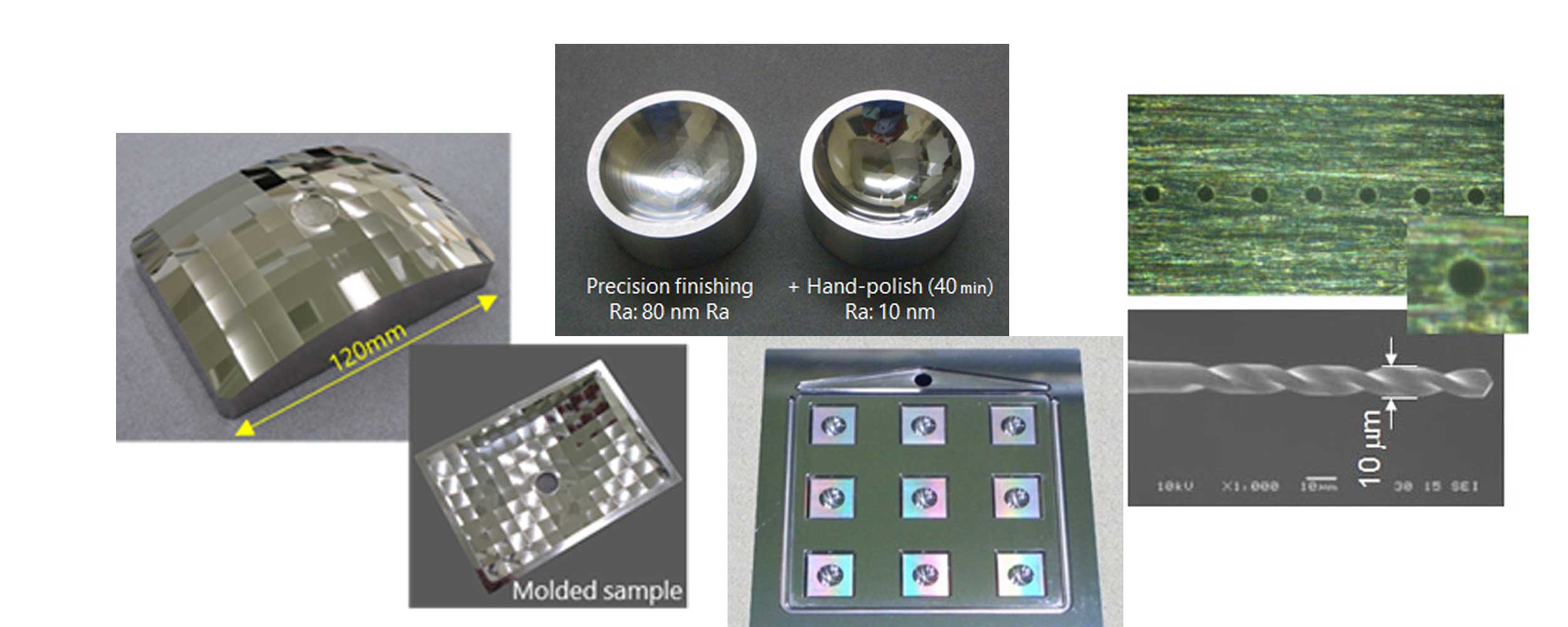

As technology advances and customer expectations rise, manufacturers face increasing challenges to produce intricate parts with exceptional precision. For example, take passenger car headlights. The parts for these headlights must meet stringent quality standards, ensuring optimal performance, safety, and aesthetics. Nano machines, notably Shibaura Machine’s UVM series, have emerged as a preferred solution for producing industrial equipment parts.

With advanced technologies and meticulous engineering, the UVM series ensures that every detail of the part is precisely replicated, resulting in flawless and consistent components. For instance, in VR devices the diffractive optics play a crucial role. Nano machines can intricately etch diffractive patterns on the lens surface, controlling light paths and enabling advanced optical functions. The machine's ability to work with tight tolerances allows for complex geometries, intricate patterns, and precise features that meet exact specification requirements.

Additionally, with high-speed machining capabilities and reduced setup times, manufacturers can accelerate their production processes, reduce lead times, and meet tight deadlines, giving them a competitive edge in the market.

While precision and quality are paramount, cost-effectiveness also remains a significant consideration for manufacturers. UVM machines' efficient use of materials, reduced waste, and optimized machining strategies result in cost savings. This makes the machine a financially viable solution for producing industrial equipment parts.

Meet Demand Head On

As the market for high-quality parts for industrial equipment rises, nano machines emerge as the innovative solution. By incorporating the UVM series, manufacturers can transform their production processes and achieve new levels of precision and efficiency.

Manufacturing intricate parts with nano-level accuracy opens up new possibilities for design and innovation, allowing manufacturers to stay ahead of the curve in the ever-evolving industry of industrial equipment. Contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

Enabling High Precision Machining with the UVM Series Nano Machines

ELK GROVE VILLAGE, IL, July 19, 2023 - Manufacturers continually seek innovative solutions to satisfy customer demands as industries increasingly require greater levels of precision, reliability, and complexity with their applications. Many are turning to ...

Read moreHow Manufacturers Can Meet the Demands of the Renewable Energy Market

ELK GROVE VILLAGE, IL, July 12, 2023 - As the world prioritizes sustainability and environmental responsibility, the renewable energy sector is undergoing a significant transformation. Countries and industries worldwide are seeking cleaner and more sustain...

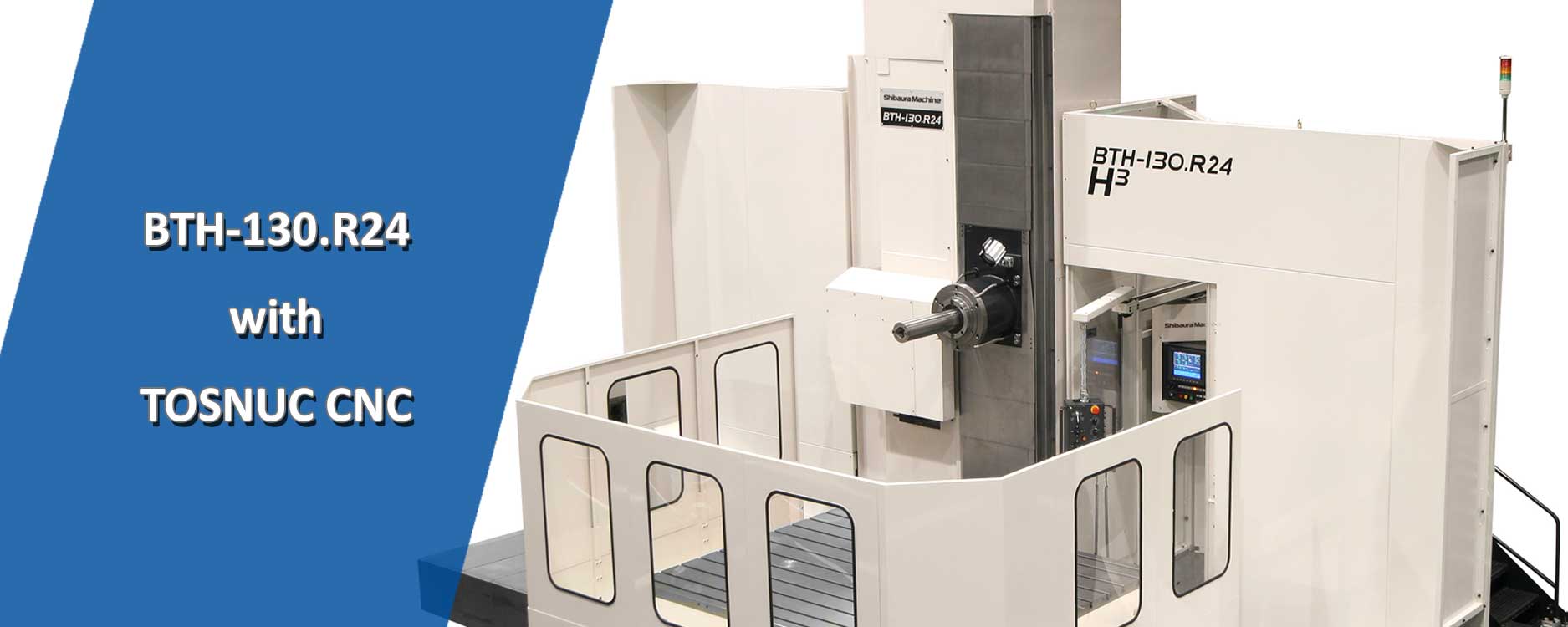

Read moreEmpowering Manufacturers: The BTH-130.R24 and TOSNUC Control System for Precision, Efficiency, and Operational Ease

ELK GROVE VILLAGE, IL, June 27, 2023 - Precision, efficiency, and ease of operation are paramount for manufacturers seeking to gain a competitive edge. Are you taking full advantage of the capabilities of your TOSNUC control system when it comes to your BT...

Read moreDriving Success in High Mix Low Volume Production: Multi-Tasking Machines and Attachment Changers as Key Enablers

ELK GROVE VILLAGE, IL, June 19, 2023 - In the ever-changing landscape of manufacturing, businesses face the challenge of adapting to diverse customer demands while maintaining operational efficiency. High mix low volume (HMLV) production has emerged as a g...

Read moreFlexibility as a Competitive Advantage: Embracing the Latest Trends in Machine Tools

ELK GROVE VILLAGE, IL, June 5, 2023 - Global trends in the machine tool industry are leaning towards greater flexibility, driven by the evolving needs and demands of manufacturers across various sectors. Traditionally, machine tools were designed for speci...

Read moreWhen Size Does Not Determine Accuracy: Breaking Stereotypes with Large Machine Tools

ELK GROVE VILLAGE, IL, May 30, 2023 - In the world of machine tools, precision is often associated with smaller workzone machines or those with limited travel or reach. It's as if the prevailing belief is that accuracy diminishes as the size and scope of t...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools