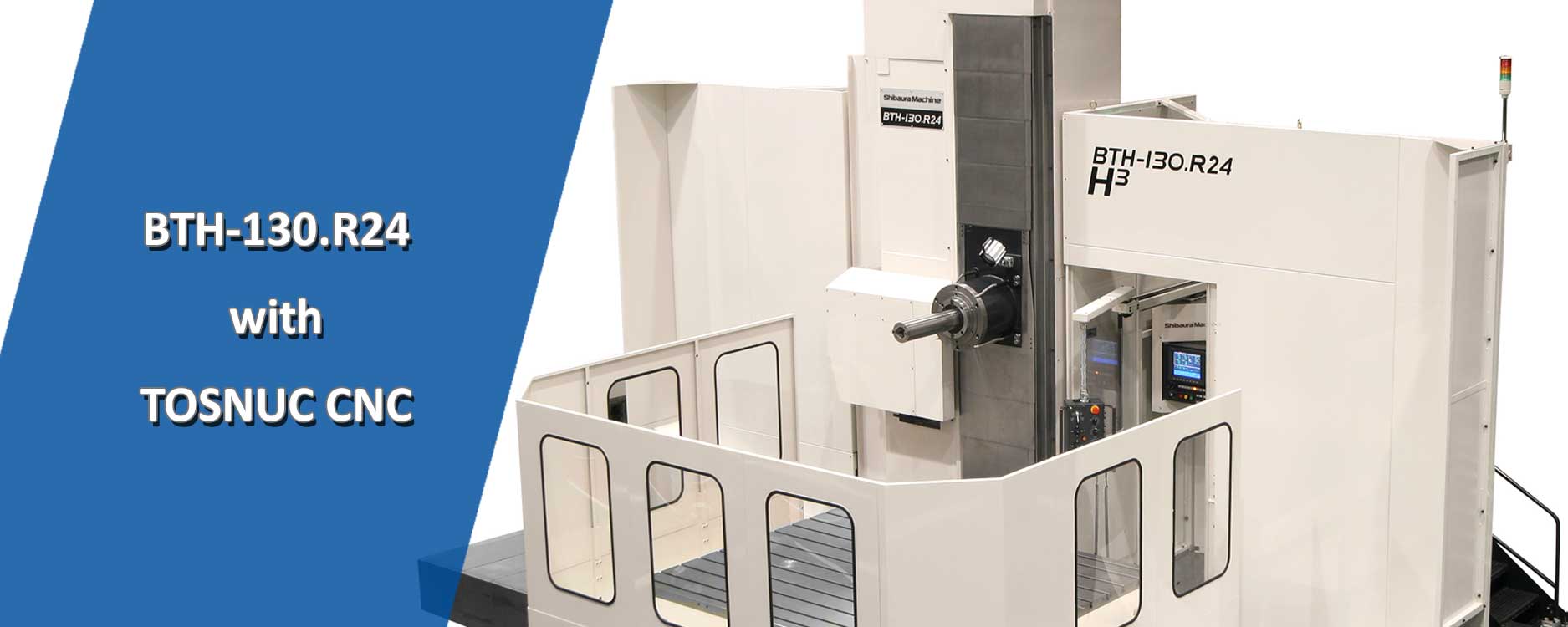

Empowering Manufacturers: The BTH-130.R24 and TOSNUC Control System for Precision, Efficiency, and Operational Ease

ELK GROVE VILLAGE, IL, June 27, 2023 -

Precision, efficiency, and ease of operation are paramount for manufacturers seeking to gain a competitive edge. Are you taking full advantage of the capabilities of your TOSNUC control system when it comes to your BTH-130.R24 horizontal boring machine?

High-speed machining capabilities paired with adaptive control functions means the BTH-130.R24 minimizes cycle times, increases overall productivity, and optimizes cutting conditions, resulting in improved surface finish and superior machining quality. These features empower manufacturers to achieve precise and efficient machining results.

Take a closer look at how to use the features of the horizontal boring machine integrated with the TOSNUC to make your work more efficient, productive, and streamlined.

Seamless Setup and Workpiece Configuration

Intuitive interfaces enable easy input and modification of workpiece details, reducing setup time and increasing productivity. With quick and accurate setup facilitated by the TOSNUC system, downtime is minimized, allowing for seamless transitions between machining operations.

Efficient Tool Selection and Management

The TOSNUC features a comprehensive tool library that simplifies tool selection and organization, streamlining the machining process. Automatic tool management during machining reduces tool changeover time, further improving overall productivity. The streamlined tool management system on the BTH-130.R24 optimizes tool performance, ensuring consistent and reliable machining results.

Precision Programming and Path Generation

Operators can choose between manual data input and local area network (LAN) connectivity, enabling flexibility and compatibility. An extensive range of functions allows for precise definition of tool paths, control of spindle speeds, and management of coolant flow on the BTH-130.R24. Enhanced programming capabilities enable tailored machining instructions, meeting specific requirements with accuracy.

Real-time Monitoring and Control

The TOSNUC control system on the BTH-130.R24 provides real-time feedback on crucial machining parameters, allowing operators to make adjustments on the fly and optimize performance. Live monitoring of spindle speed, feed rate, tool position, and tool wear ensures precision and efficiency.

Efficient Data Management and Connectivity

The TOSNUC offers built-in data storage and retrieval capabilities, simplifying data management on the BTH-130.R24. Operators can easily access programs, tooling information, and workpiece configurations, enhancing workflow efficiency. Connectivity options enable seamless data transfer between the machine and external devices, facilitating efficient data exchange and improving overall productivity. Enhanced data organization ensures quick retrieval of information, supporting streamlined operations and reducing downtime.

Unlock New Levels of Precision and Efficiency

The Shibaura Machine BTH-130.R24 horizontal boring machine, equipped with the advanced TOSNUC control system, offers manufacturers an unparalleled combination of precision and efficiency. Contact the Machine Tool team to learn more about how this combination can transform your machining operations and drive your business forward.

Related Articles View All Machine Tools Articles

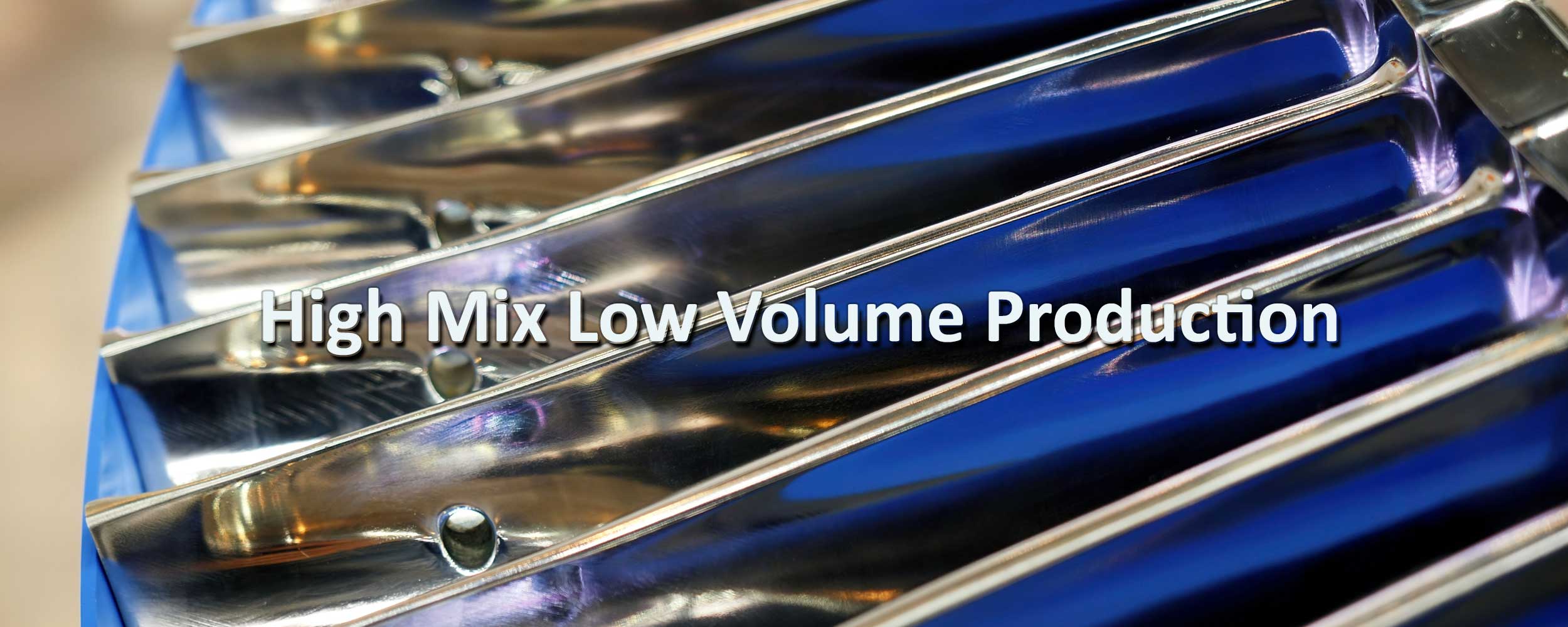

Driving Success in High Mix Low Volume Production: Multi-Tasking Machines and Attachment Changers as Key Enablers

ELK GROVE VILLAGE, IL, June 19, 2023 - In the ever-changing landscape of manufacturing, businesses face the challenge of adapting to diverse customer demands while maintaining operational efficiency. High mix low volume (HMLV) production has emerged as a g...

Read moreFlexibility as a Competitive Advantage: Embracing the Latest Trends in Machine Tools

ELK GROVE VILLAGE, IL, June 5, 2023 - Global trends in the machine tool industry are leaning towards greater flexibility, driven by the evolving needs and demands of manufacturers across various sectors. Traditionally, machine tools were designed for speci...

Read moreWhen Size Does Not Determine Accuracy: Breaking Stereotypes with Large Machine Tools

ELK GROVE VILLAGE, IL, May 30, 2023 - In the world of machine tools, precision is often associated with smaller workzone machines or those with limited travel or reach. It's as if the prevailing belief is that accuracy diminishes as the size and scope of t...

Read moreHow the BSF-150C Floor-Type Boring and Milling Machine Enhances Accuracy in Large Workpiece Machining

ELK GROVE VILLAGE, IL, May 23, 2023 - As the demand for high cutting performance, less downtime, and improved productivity increases for machining medium and large-sized parts, floor-type horizontal boring and milling machines have become more popular. Shi...

Read moreThe Smart Choice for Chip and Coolant Management: Introducing the TUE Series Top Cover

ELK GROVE VILLAGE, IL, May 9, 2023 - As technology continues to evolve, so do the challenges that arise in the manufacturing industry. One of the challenges that persist is managing coolant and chips in the machining process. Having a well-designed chip an...

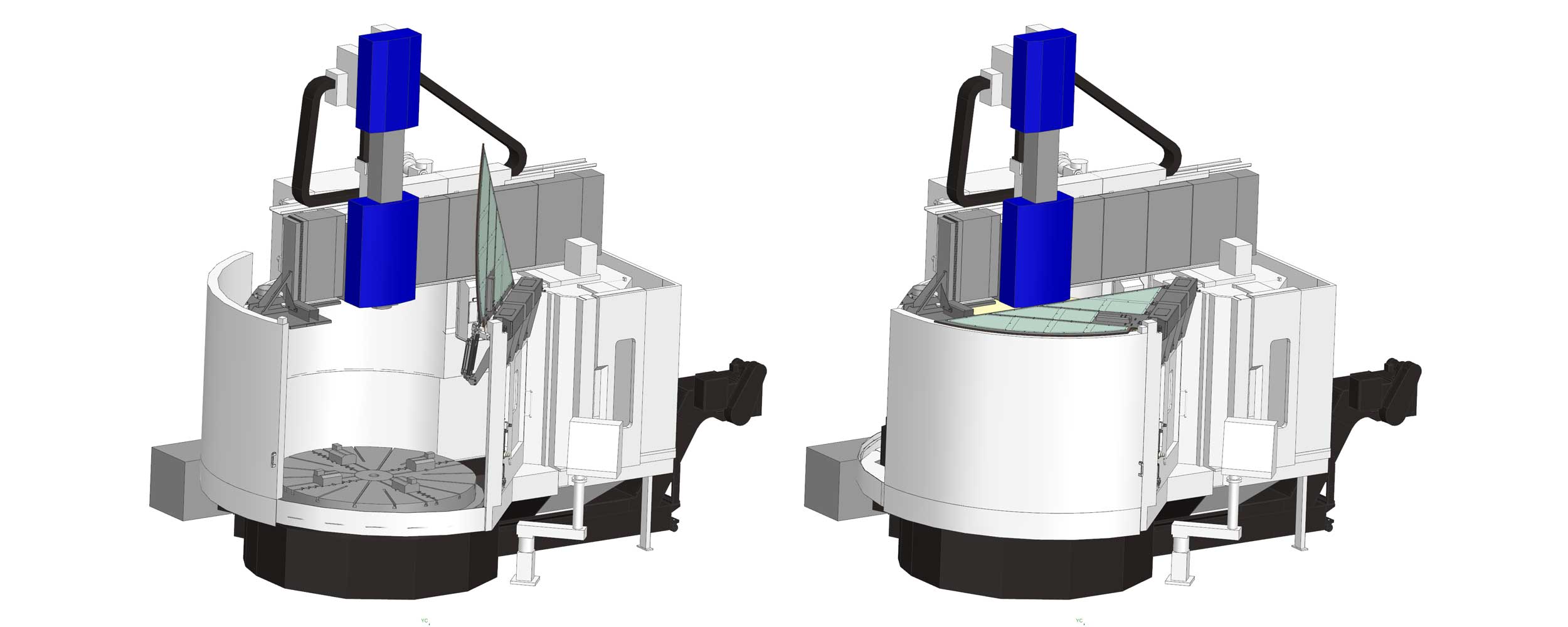

Read moreThe Multi-tasking Capabilities of the Mill-Turn Machine Tool

ELK GROVE VILLAGE, IL, April 25, 2023 - Transitioning between machine tools is one of the biggest challenges for machinists. This can result in human errors during setup and the accumulation of processing errors. As a solution, multi-tasking tools are beco...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools