The Multi-tasking Capabilities of the Mill-Turn Machine Tool

ELK GROVE VILLAGE, IL, April 25, 2023 -

Transitioning between machine tools is one of the biggest challenges for machinists. This can result in human errors during setup and the accumulation of processing errors. As a solution, multi-tasking tools are becoming increasingly popular. These machines are capable of performing several different tasks all in one, rather than requiring separate machines for each operation.

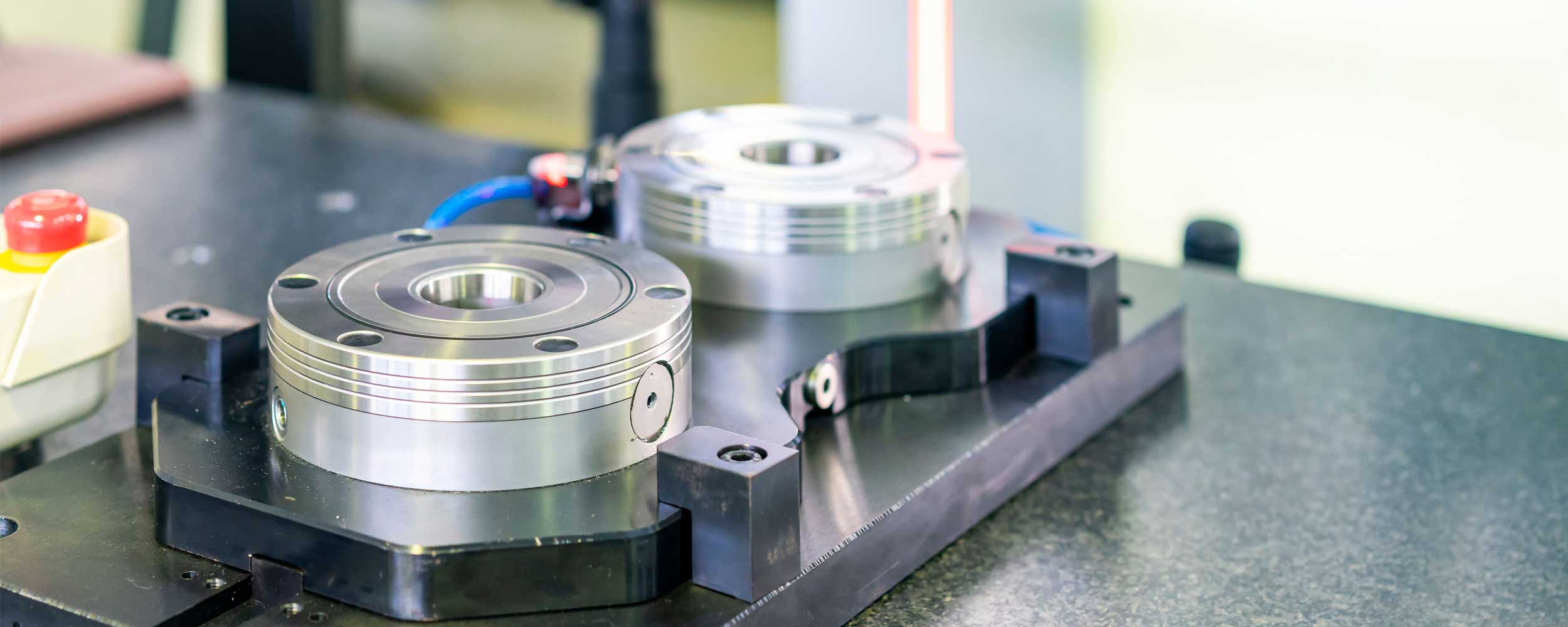

Multi-tasking machines can greatly increase efficiency, reduce lead times, and lower costs. The mill-turn is a type of multi-tasking machine tool that combines the capabilities of a lathe and milling into a single machine. The MP-U and MCW series by Shibaura Machine are examples of mill-turn machines that can carry out multiple functions including turning, milling, drilling, and tapping, all in a single setup. This eliminates the need for the workpiece to be transferred between different machines, resulting in increased accuracy, reduced setup time, and improved productivity.

Versatility and Precision in One

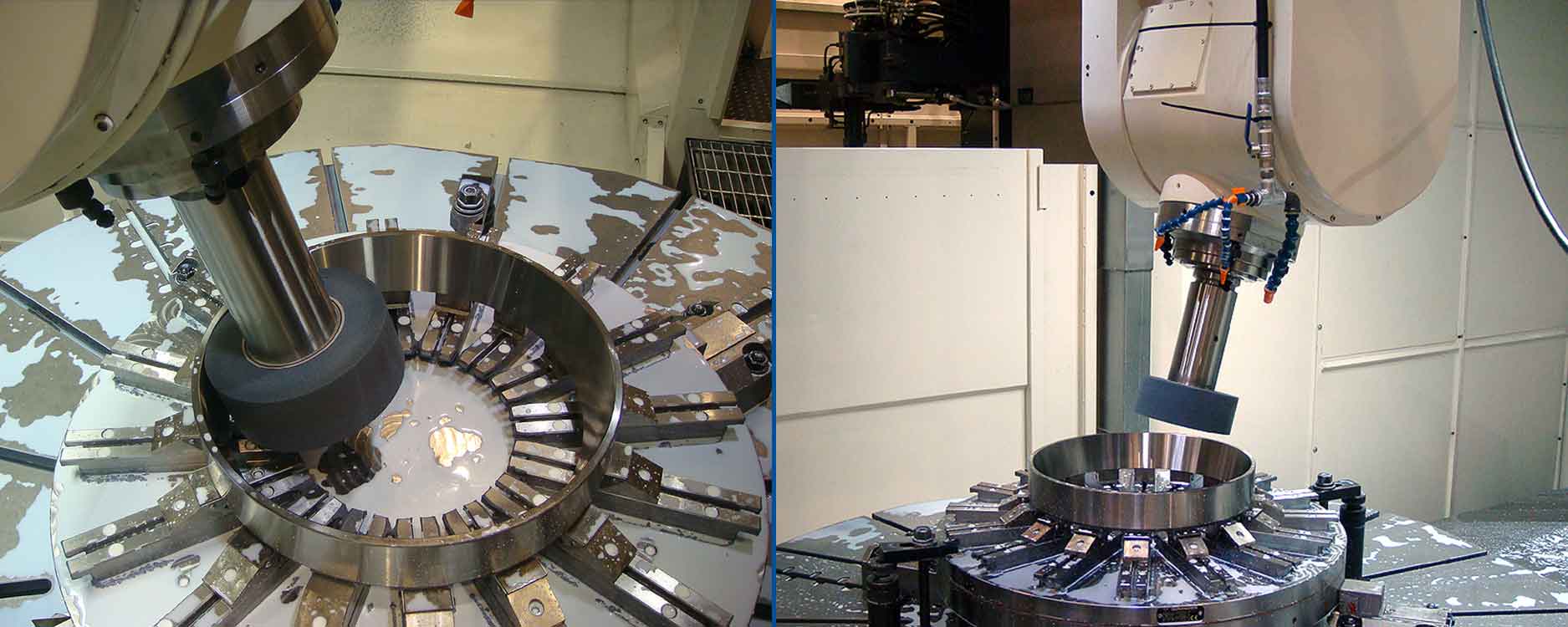

The mill-turn machine is equipped with a live spindle function, which allows the tool to rotate while the workpiece is held stationary. It can be a vertical or horizontal lathe, with the recent versions offering a variety of options, such as a Y-axis movement and a tilting head for positioning. By giving one machine the functions of two or three machines, the number of machinists required can be reduced, resulting in significant cost savings.

The MP-U bridge-style and MCW gantry-style allow the machinist to perform a wide range of applications in a single machine. By attaching a lathe table with a table indexing mechanism to a gate-type 3-axis machine and exchanging attachments, it can function as a 5-axis machine. This means it can be used for various types of processing, including horizontal boring, lathe machining, and 5-axis machining, all with a single machine. It's a multi-functional machine that can handle the processing that previously required two machines, resulting in significant time savings, reduced setup time and the number of machinists required.

Mill-Turn Machine Applications

The choice of machine will depend on the specific needs of the application, including the size and complexity of the workpiece being machined, as well as the required production volume.

Mill-turn machines can be used for a wide range of applications, including machining complex parts with intricate geometries, such as those used in the aerospace, automotive, and medical industries. The machines are capable of producing high precision parts with tight tolerances, making them ideal for use in applications where accuracy is required.

One example of a complex machining application that the mill-turn machine is well suited for is the machining of gas turbine and jet engine parts. The machining of these parts is intricate, requiring both lathe machining and 5-axis machining. Additionally, these parts can be made from various materials, making a single machine capable of processing them a must-have. The mill-turn machine's 5-axis capability and its ability to handle multiple types of processing with a single machine makes it a valuable addition to any machine shop.

A Partner in Machining Excellence

When selecting a mill-turn machine, it's essential to consider the manufacturer's experience in producing 3-axis bridge mill machines, vertical turning lathes, 5-axis machining, and automation. With over 140 years of experience in the machine tools industry, Shibaura Machine is known for its high-quality and innovative machine tools designed to increase productivity, reduce cycle time, and improve accuracy.

Mill-turn multi-tasking machines are a valuable addition to any machine shop and can handle complex machining applications that require lathe and 5-axis machining. Contact the Machine Tool team to learn more about the MP-U and MCW series.

Related Articles View All Machine Tools Articles

Exploring the Versatility of Dynamic Part Probing for CNC Machine Tools

ELK GROVE VILLAGE, IL, April 19, 2023 - Dynamic part probing is a powerful tool that has transformed the way CNC machine tools operate in manufacturing. By using sensors and software to collect and analyze data in real-time during the machining process, dy...

Read morePrecise Machining on the MP-(U) for Challenging Materials with the Grinding Attachment

ELK GROVE VILLAGE, IL, April 05, 2023 - Multi-tasking machine tools have revolutionized the manufacturing industry, providing a versatile and efficient solution to various machining requirements. These machines are designed to perform several functions all...

Read moreMaximizing Horizontal Boring Machine Performance with TOSNUC and FANUC CNC Control Systems

ELK GROVE VILLAGE, IL, March 28, 2023 - Horizontal Boring Machines (HBM) have quickly become a critical component in the manufacturing process of various industries, and their precision and efficiency are vital for achieving high-quality results. One of th...

Read moreStart Improving Production With the Help of a Quick Change Workholding

ELK GROVE VILLAGE, IL, March 22, 2023 - In the world of manufacturing, time is money. Any downtime or delay in the production process can have a significant impact on a company's bottom line. This is where quick change workholding comes into play. Also kno...

Read moreMaximizing Efficiency in Machining with the Right Angle Head Attachment on your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 14, 2023 - As a machine tool operator, you know that there are many challenges involved in performing precision cutting, drilling, and other operations. Machining complex workpieces with multiple surfaces often require numerous...

Read moreBoost Your CNC Machining Confidence: On-Site Training Explained

ELK GROVE VILLAGE, IL, March 7, 2023 - As the manufacturing industry continues to grow and evolve, it's becoming increasingly important for companies to invest in their workforce through proper training programs.In the world of machine tools, on-site train...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools