Exploring the Versatility of Dynamic Part Probing for CNC Machine Tools

ELK GROVE VILLAGE, IL, April 19, 2023 -

Dynamic part probing is a powerful tool that has transformed the way CNC machine tools operate in manufacturing. By using sensors and software to collect and analyze data in real-time during the machining process, dynamic part probing provides a wealth of information that can be used to improve accuracy, efficiency, and productivity.

While probing is commonly employed for straightforward job set-up tasks, the use of dynamic part probing has the potential to deliver a significant amount of valuable data throughout the manufacturing cycle that might otherwise go unnoticed. By analyzing and responding to this information, a machine tool can minimize the need for operator intervention and enhance the probability of producing precise components. From measuring the position and dimensions of a workpiece to inspecting surfaces for defects, dynamic part probing has numerous applications that are invaluable for modern manufacturing.

Improving Manufacturing Precision and Efficiency

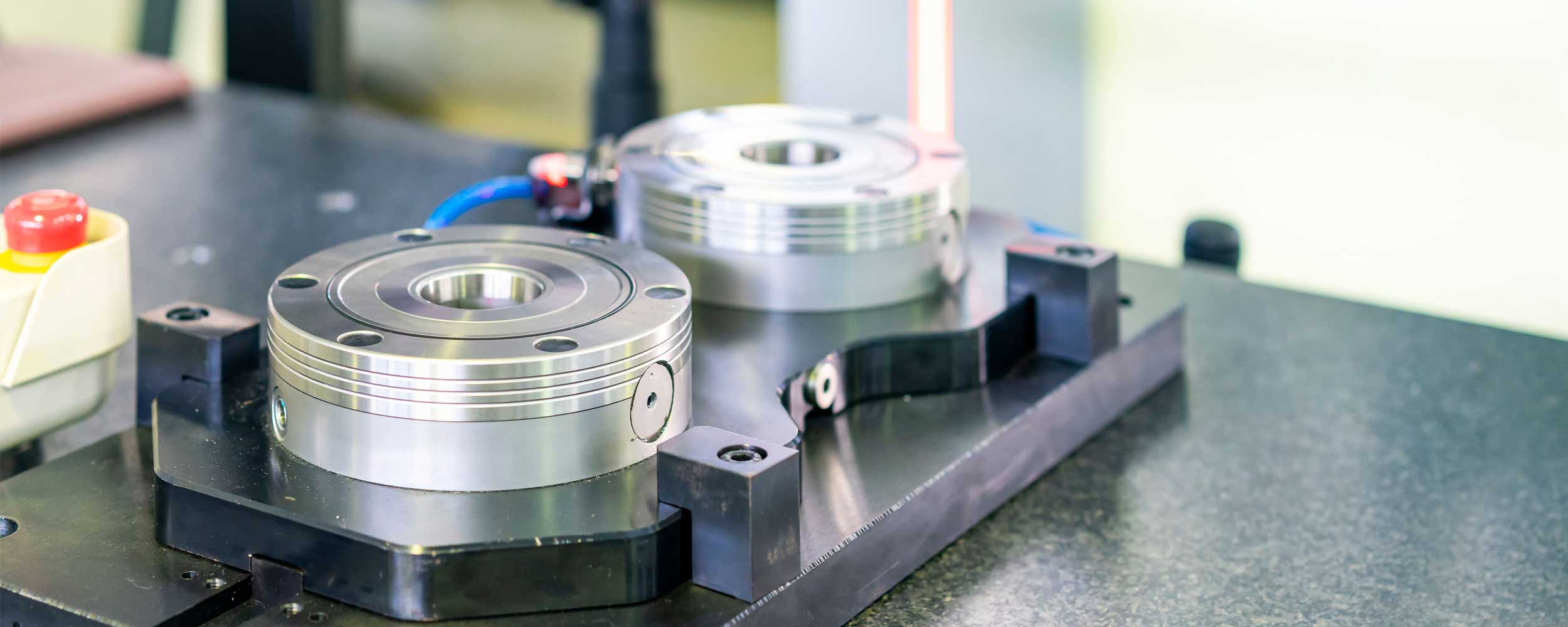

Dynamic part probing is done by touching a probe to various points on the workpiece either by establishing a data point on the workpiece prior to machining or after the machining process is complete.

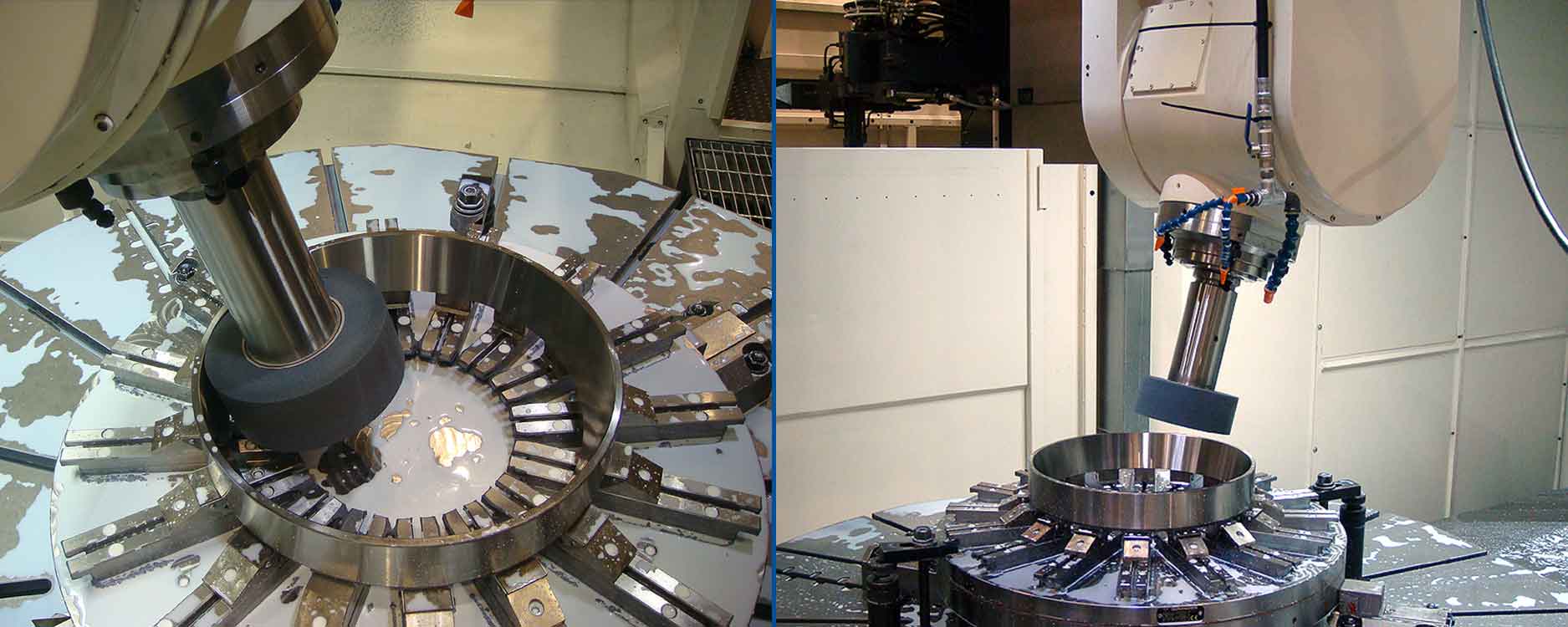

In a CNC milling machine, such as Shibaura Machine’s BTH-130.R24, a touch probe can be used to measure the position and dimensions of the workpiece throughout the machining process. The probe can be programmed to take measurements at specific intervals, allowing for real-time adjustments to the machining process.

Another example is with the Shibaura Machine TUE Series of vertical turning lathes, a probe can be used to measure the surface of the workpiece throughout the machining process. This information can be used to adjust the cutting parameters to achieve the desired feature.

Additional capabilities of dynamic part probing:

- Tool length measurement

- Workpiece location

- Workpiece dimension measurement

- Feature location

Which Dynamic Probing Tool is Right for My CNC Machine?

When choosing a dynamic probing tool for your CNC machine, factors such as the type of machine tool, probing application, and required accuracy and repeatability must be taken into account. Additionally, high accuracy and repeatability may be necessary for applications with tight tolerances. Proper consideration of these factors can lead to improved productivity, quality, and efficiency in the manufacturing process.

Contact the Shibaura Machine Tool Team to learn more about equipping your CNC machine with a dynamic part probing tool to achieve higher levels of quality and profitability.

Related Articles View All Machine Tools Articles

Precise Machining on the MP-(U) for Challenging Materials with the Grinding Attachment

ELK GROVE VILLAGE, IL, April 05, 2023 - Multi-tasking machine tools have revolutionized the manufacturing industry, providing a versatile and efficient solution to various machining requirements. These machines are designed to perform several functions all...

Read moreMaximizing Horizontal Boring Machine Performance with TOSNUC and FANUC CNC Control Systems

ELK GROVE VILLAGE, IL, March 28, 2023 - Horizontal Boring Machines (HBM) have quickly become a critical component in the manufacturing process of various industries, and their precision and efficiency are vital for achieving high-quality results. One of th...

Read moreStart Improving Production With the Help of a Quick Change Workholding

ELK GROVE VILLAGE, IL, March 22, 2023 - In the world of manufacturing, time is money. Any downtime or delay in the production process can have a significant impact on a company's bottom line. This is where quick change workholding comes into play. Also kno...

Read moreMaximizing Efficiency in Machining with the Right Angle Head Attachment on your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 14, 2023 - As a machine tool operator, you know that there are many challenges involved in performing precision cutting, drilling, and other operations. Machining complex workpieces with multiple surfaces often require numerous...

Read moreBoost Your CNC Machining Confidence: On-Site Training Explained

ELK GROVE VILLAGE, IL, March 7, 2023 - As the manufacturing industry continues to grow and evolve, it's becoming increasingly important for companies to invest in their workforce through proper training programs.In the world of machine tools, on-site train...

Read moreMachine Tool Automation Options for Shibaura Machine's TMD Series

ELK GROVE VILLAGE, IL, February 28, 2023 - Efficiency and productivity are critical factors for success in today's fast-paced manufacturing industry. To maintain a competitive edge, manufacturers must continually seek new ways to optimize their processes a...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools