Why High-Volume Coolant Provides a Cutting Advantage for Machine Tools

ELK GROVE VILLAGE, IL, June 28, 2022 -

Coolants play an important role in machining. Reducing the amount of heat and friction when your tool point is cutting into a workpiece means it allows for higher cutting speeds and reduced tool wear.

At lower volumes, the coolant is not able to as effectively remove chips from the cutting area. This can mean a possibility of re-cutting chips and having a negative impact on the part’s surface finish.

The effect the coolant provides can be enhanced in many cases with high-volume delivery. With high-value machine tools delivering higher spindle speeds and improved workpiece tolerancing, a higher volume coolant allows manufacturers to achieve maximum performance with better cutting capabilities.

Cutting Benefits of High-Volume Coolant

Using a high-volume coolant strategy will allow manufacturers to reduce cost-per-part, while also measurably improving productivity.

Manufacturers recognize several cutting benefits associated with higher volume coolant:

- With a higher volume of coolant flowing, chips are more easily flushed away from the cutting area.

- The chip conveyor can more easily remove the chips from the machine.

- Increased cutting speed in tough-to-cut materials such as titanium and nickel alloys.

Learn More

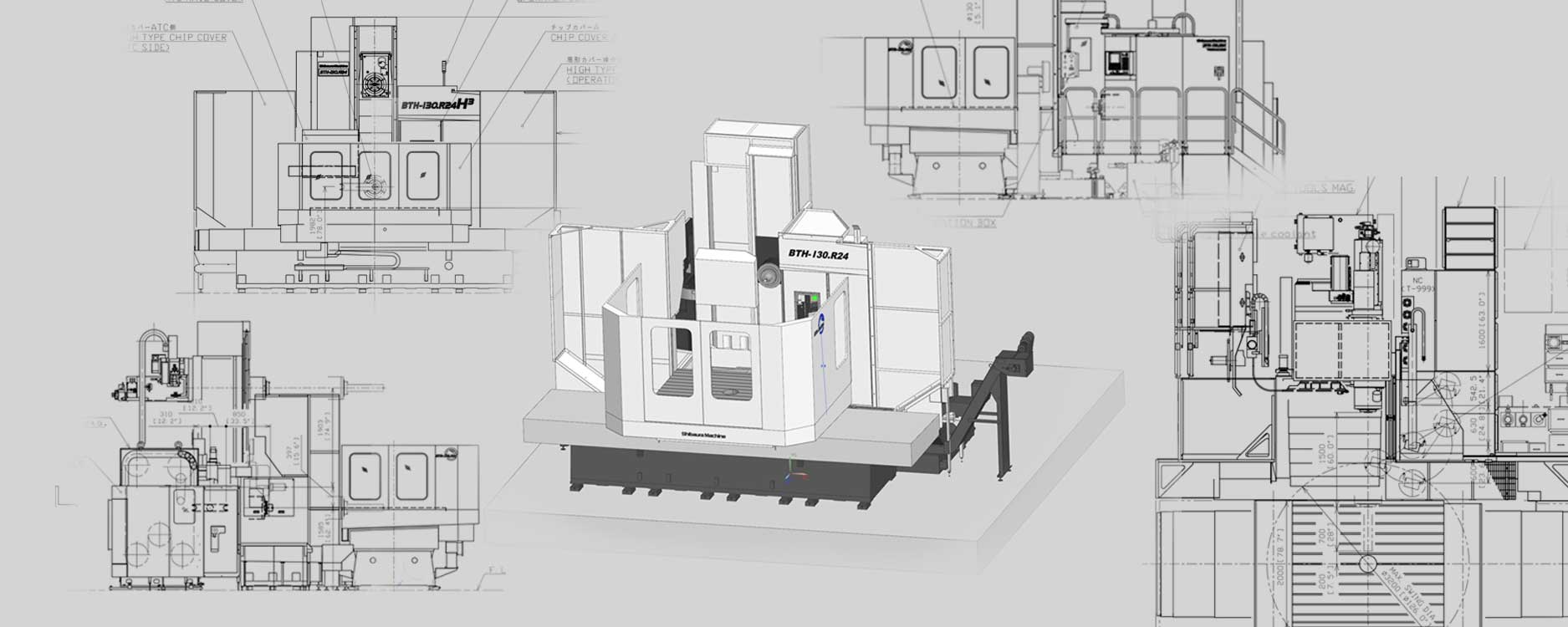

Incorporating a high-volume coolant system provides the ideal advantage when applied properly to the tool cutting zone. Getting the greatest cutting benefits from high-volume coolant requires a thorough understanding of the cutting application to make sure the higher volume of coolant is delivered with the precise flow and pressure. For this reason, Shibaura Machine provides several machine tools that offer higher volume of coolant which allows us to serve customers with difficult machining applications.

Contact the Machine Tools team to learn more about our high-volume coolant options.

Related Articles View All Machine Tools Articles

Replacement Part Ordering Made Easy

ELK GROVE VILLAGE, IL, June 20, 2022 - Before purchasing a new machine tool there are a lot of questions to be asked. These can include “What is the rigidity of the machine?” to “Does the company have a good reputation?”. Often forgotten is the line of que...

Read moreLooking Beyond Standard Maintenance to Improve Machine Tool Life

ELK GROVE VILLAGE, IL, June 14, 2022 - Your machine tool is a major investment and with that, you expect a long service life. While Shibaura Machine takes extensive measures to engineer world-class equipment, some still in use after 30+ years, it is also c...

Read moreSimplifying Machine Tool Importation For Our North American Customers

ELK GROVE VILLAGE, IL, June 6, 2022 - Shopping for the right machine tool can be complex.From choosing a machine tool to meet production and budgetary requirements to ensuring importation procedures are met and machinery is compliant with North American re...

Read moreHow We’re Helping You Create a World Class Manufacturing Facility

ELK GROVE VILLAGE, IL, May 31, 2022 - Is it worth the time to review and put together a facility layout? The answer is a resounding yes. From being able to speed up your process, improve productivity, and even maximize square footage your facility layout c...

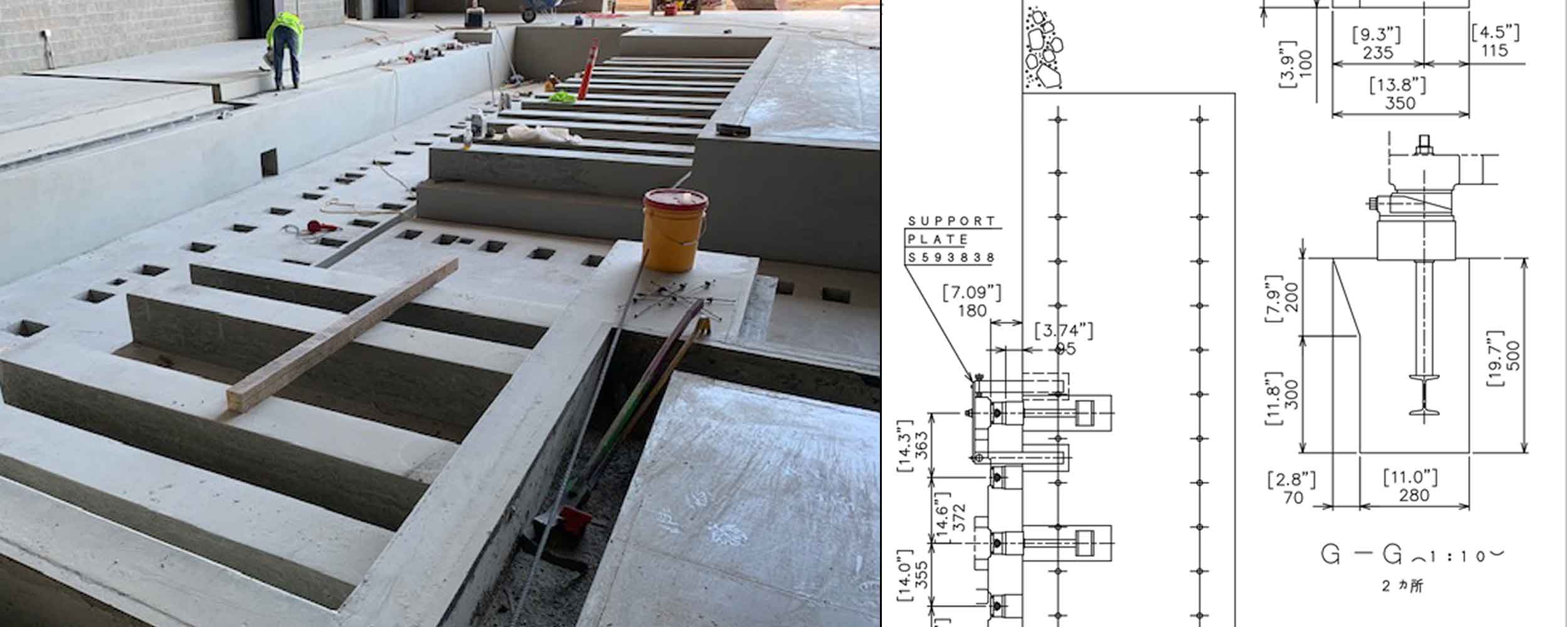

Read moreUnderstanding the Importance of Foundations for Precision Machine Tools

ELK GROVE VILLAGE, IL, May 23, 2022 - Would a contractor ever build a house without a solid foundation? The answer is a resounding no. Without a solid foundation not only will the home be unstable, but will likely bring in unwanted outside elements. The sa...

Read moreConsider High-Pressure Coolant to Improve Chip Management

ELK GROVE VILLAGE, IL, May 16, 2022 - Managing machine tool cutting variables such as feeds, speeds and depth of cut play a key role in eliminating unpredictable cutting tool wear and poor chip management. Incorporating a high pressure coolant system will ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools