Increase Double-Column Machine Capabilities With These Attachments

ELK GROVE VILLAGE, IL, March 28, 2022 -

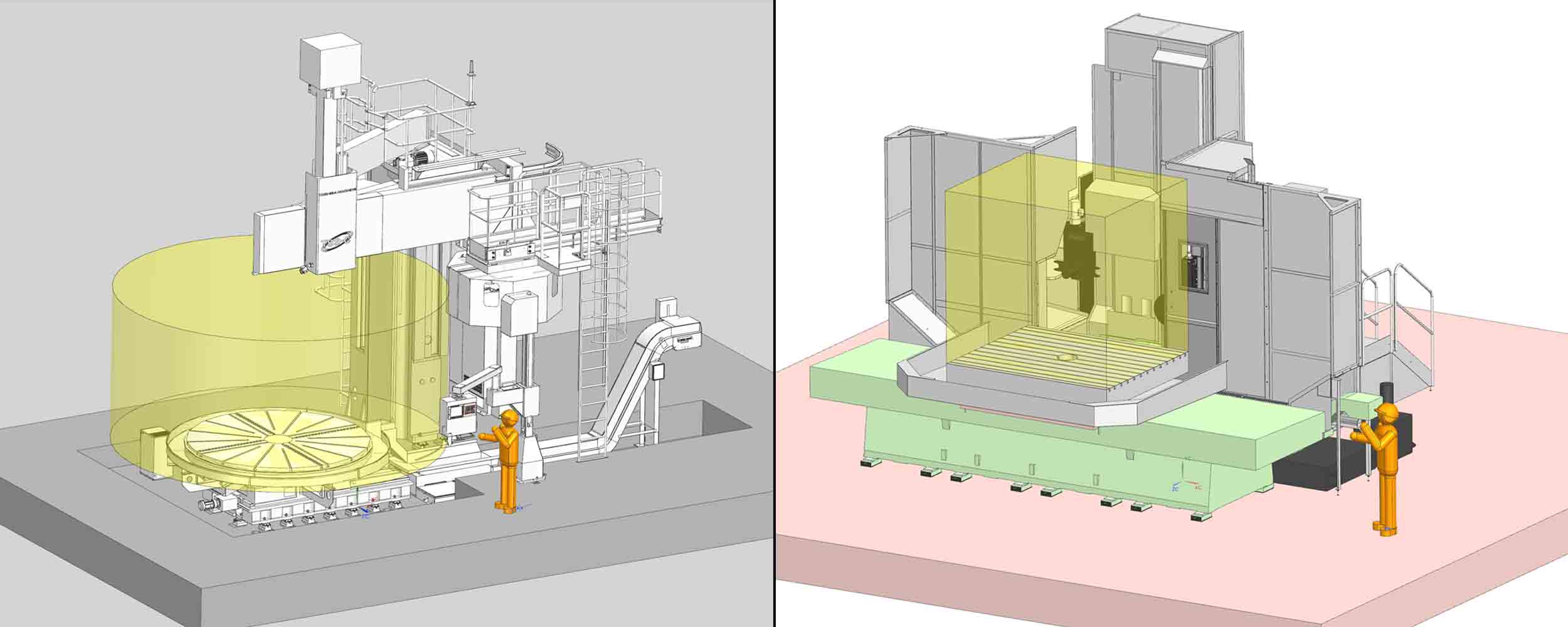

When it comes to choosing a double-column machine there are several considerations you’ll want to take. Is it high-performance, does it provide the stability and power required to deliver uninterrupted precision? Can it meet the needs of process-oriented industries like aerospace, automotive, oil and gas, or energy? While checking these boxes is imperative, you will also want to consider the attachment system and variety of attachments that are available with the machine.

All high-performance, double-column machines from Shibaura Machine are configurable with automatic attachment changers to save valuable machining time and improve process tolerances. An abundant range of attachments are compatible with the machines, which allow for increased machining capability and includes a wider range of unique workpieces to be created.

Increase Machine Process Flexibility With Attachments

When your customer has big, heavy workpieces you look to your Shibaura Machine double-column machines to provide the rigidity and reliability to handle your production requirements. Below is a variety of attachments that can help further improve the machining process.

ANGLE HEADS

A 5-sided machining strategy utilizing the angle head or fixed 30-degree angle head attachment will improve machine tool production and the accuracy of the workpiece by machining multiple surfaces in one setup.

(Shown left to right: Angle head and 30-degree angle head)

SNOUT VERTICAL EXTENSION

1 DEGREE INDEX HEAD

A 5-axes machining strategy utilizes a 1-degree indexing machine attachment with 2 rotary axes, which allows a vector cutting tool approach to reduce or eliminate complex workpiece fixturing.

4 AXIS HEAD

5-FACE CUTTER HEAD

This attachment plays a key role in determining the quality of the machine by combining its rigid construction with features that can not be duplicated. The 5-face cutter head allows for easy access to the workpiece for heavy-duty machining operations.

Automatic Attachment Changer (AAC)

The attachments are changed through the Automatic Attachment Changer. AAC automatically attaches and detaches attachments to and from the spindle securely and places them on the storage rack. All attachments are precision located to the ram face with curvic coupling for machining high accuracy and improving overall operational productivity.

Let Us Help You Find The Best Attachment For Your Application

For over 50 years, Shibaura Machine has been building precision double-column machines for the most demanding applications in precision tooling. Our assortment of attachments offers customers increased machining capabilities and growth opportunities. Contact the Machine Tool team to discuss your requirements and let us help you find the best solution for your application.

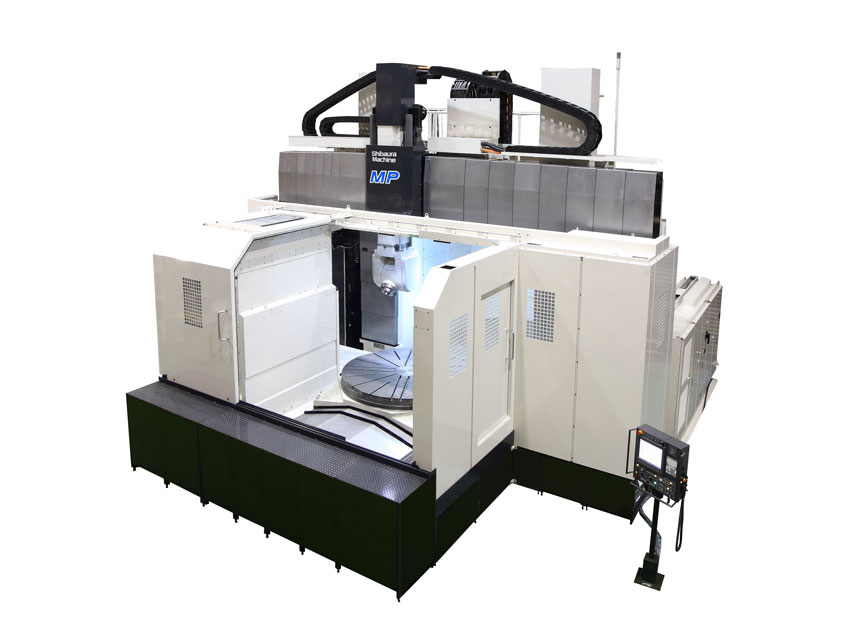

High performance Double Column/Bridge/Gantry type Machining Center

Related Articles View All Machine Tools Articles

Machining Large and Complex Workpieces? Consider These Machine Specs.

ELK GROVE VILLAGE, IL, March 21, 2022 - When it comes to machining large workpieces you need an equally large machine tool. While that might seem obvious, there are also a couple of other less than obvious factors to consider when choosing your next large ...

Read moreWhat Machining Applications are Best Suited for a Box Way Axes Guide System?

ELK GROVE VILLAGE, IL, March 14, 2022 - So, when should you use a box way axes design guideway system?Shibaura Machine’s vast range of machining solutions allows us to supply customers with a box way guide system on our machine tools in addition to linear ...

Read moreLooking to Reduce Machine Tool Setup Time? Read This.

ELK GROVE VILLAGE, IL, March 07, 2022 - Time is money. This is why so many shops find themselves looking to reduce their machine tool setup time. When the machine is not running, it’s not making money- a simple fact.In order to maximize machine tool effici...

Read moreHigh Accuracy or Surface Finish Requirements? You Don’t Have to Choose.

ELK GROVE VILLAGE, IL, March 01, 2022 - Speeding up cycle times and part production is something shops have been in hot pursuit of for years. However, this isn’t the only way to impact profitability. Shops also need to be able to ensure that they are able ...

Read moreImprove Part Program Usability with the TOSNUC 999 Macro Programming Function

ELK GROVE VILLAGE, IL, February 22, 2022 - Macro programming for CNC machining provides shops countless benefits. It offers both power and flexibility, allowing machinists to implement improvements in just about every facet of a CNC environment. Many shops...

Read moreOptimize Productivity With These Strategic Machine Shop Layout Ideas

ELK GROVE VILLAGE, IL, February 14, 2022 - Take a look at your machine shop floor. Is it maximizing space and enabling the most productive environment?One of the most overlooked solutions to improving workflow and production in CNC machining is shop floor ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools