High Accuracy or Surface Finish Requirements? You Don’t Have to Choose.

ELK GROVE VILLAGE, IL, March 01, 2022 -

Speeding up cycle times and part production is something shops have been in hot pursuit of for years. However, this isn’t the only way to impact profitability. Shops also need to be able to ensure that they are able to maintain the workpiece accuracy and surface finish requirements.

Is it possible to achieve maximum efficiency while meeting these requirements? There are a few factors to consider when looking into machine tools that will allow you to maintain performance while ensuring high quality parts.

Creating a Clear Advantage

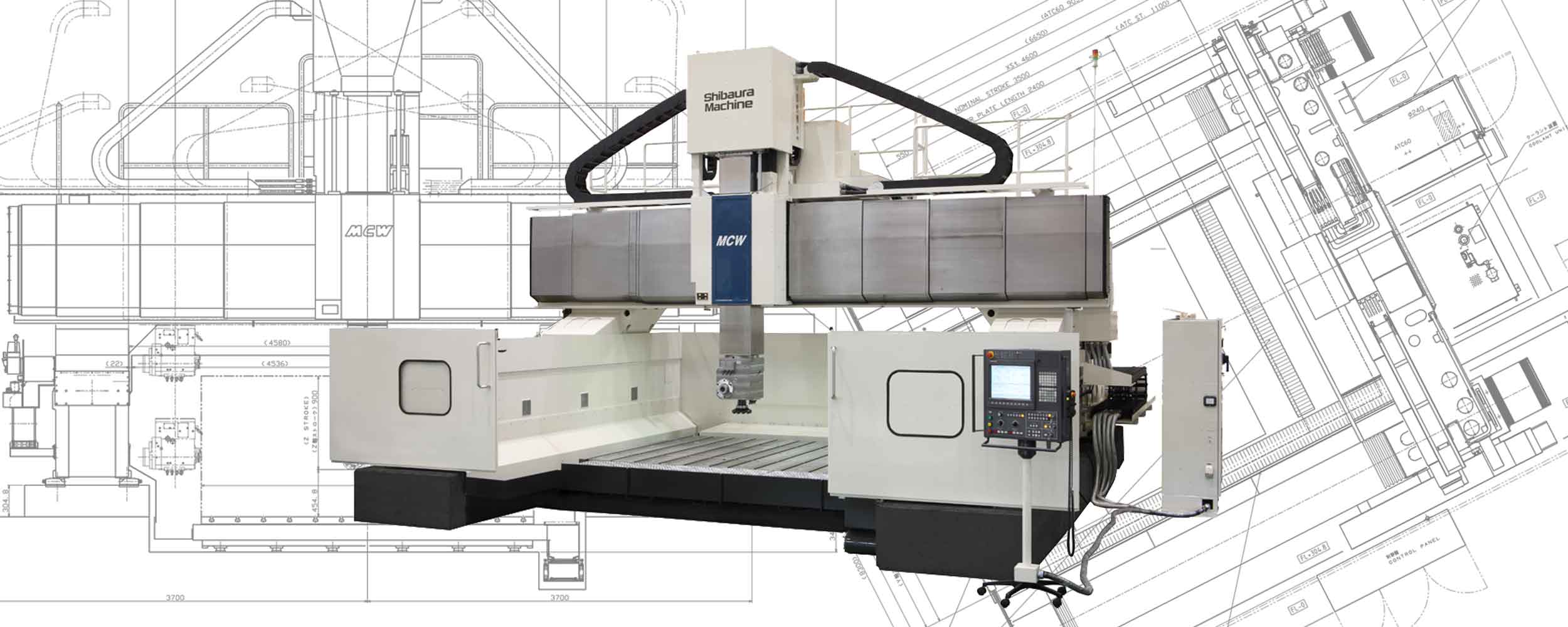

Having a machine tool that is built to meet workpiece requirements while ensuring accuracy is the best way to achieve it all. Shibaura Machine’s CNC machine tools are designed to help manufacturers increase workload and metal removal rates, while improving accuracy and part quality.

Engineered with features to ensure high quality workpieces are achieved such as:

- Latest technology capabilities to allow the machinist to manage spindle and servo axes performance

- Controlled machine alignment and geometries with linear and rotary axes scales to allow for improved accuracy and repeatability

- Tight tolerances on major machine subcomponents to ensure a quality machine

In order to minimize thermal displacement seen in production, Shibaura Machine has taken specific measures. The spindle compensation system can assist in managing thermal variations. And in order to make complex parts easier to produce, the machine design has been specifically engineered for highly efficient machine performance.

It is also critical to leverage technology to enable your CNC machine to run unattended and complete parts in one set-up on the machine tool. Shibaura Machine’s proprietary TOSNUC CNC control offers features such as the Teaching Function that allow even less experienced operators to perform machining operations. Your shop will see greater control over throughput being more machine dependent vs. operator dependent.

Challenge the Competition

Gain your competitive edge by producing high quality parts with the right machine tool and technology. Shibaura Machine is committed to helping shops change standards with machine tool solutions that don’t compromise on surface finish and accuracy capabilities.

Contact our Machine Tool Team to learn more today.

Related Articles View All Machine Tools Articles

Improve Part Program Usability with the TOSNUC 999 Macro Programming Function

ELK GROVE VILLAGE, IL, February 22, 2022 - Macro programming for CNC machining provides shops countless benefits. It offers both power and flexibility, allowing machinists to implement improvements in just about every facet of a CNC environment. Many shops...

Read moreOptimize Productivity With These Strategic Machine Shop Layout Ideas

ELK GROVE VILLAGE, IL, February 14, 2022 - Take a look at your machine shop floor. Is it maximizing space and enabling the most productive environment?One of the most overlooked solutions to improving workflow and production in CNC machining is shop floor ...

Read moreImprove CNC Operation Efficiency with Customized Keys on TOSNUC 999

ELK GROVE VILLAGE, IL, February 08, 2022 - While CNC machines are excellent at doing what they are programmed to do, it is the machine operator's role to make sure they are commanded accurately. That is why being able to properly navigate the control panel...

Read moreHow LAN Linkage is Improving Operational Efficiency

ELK GROVE VILLAGE, IL, January 31, 2022 - When it comes to connecting a CNC machine to your network, doing so benefits the bottom line by increasing productivity and improving uptime. With local area network (LAN) connectivity, shops are able to easily sen...

Read moreLarge workpiece, but short on space? Here’s your solution.

ELK GROVE VILLAGE, IL, January 24, 2022 - Machine tools that can meet the demands of large parts and difficult to cut materials while providing increased efficiency and precision are in growing demand. Industries like oil and gas, automotive, aerospace, mi...

Read moreMachine Tool Operations Made Simple with the Manual Pendant

ELK GROVE VILLAGE, IL, January 17, 2022 - Any way that efficiency can be improved is important in the competitive world of machining. Improving efficiency not only helps cut costs, but throughput of the shop. And while there are plenty of ways to improve p...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools