How LAN Linkage is Improving Operational Efficiency

ELK GROVE VILLAGE, IL, January 31, 2022 -

When it comes to connecting a CNC machine to your network, doing so benefits the bottom line by increasing productivity and improving uptime. With local area network (LAN) connectivity, shops are able to easily send application data quickly with seamless integration.

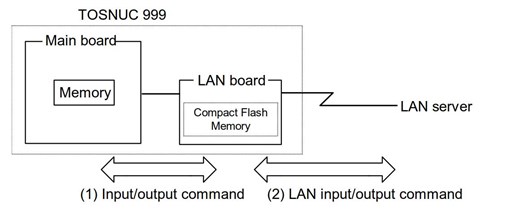

The Shibaura Machine TOSNUC 999 controller provides manufacturers connectivity to the machine tool through LAN. When the high-speed LAN Linkage function is used, program and other data is able to be transferred between the CNC and host computer through LAN connection.

Save Space, Save Time

Without having to install additional software, the LAN Linkage allows shops to gather part programs easily from their machine tools to track productivity and more. Oftentimes providing a seamless integration to existing applications, shops can pass part programs and off-set data to the office environment or higher-level system within their factory automation infrastructure.

Another benefit to LAN Linkage connectivity is that shops can easily share pertinent information. For example, CNC part programs developed in one location can be downloaded directly to the FTP server and viewed in another facility allowing manufacturers to seamlessly exchange data and expedite their processes. Large programs are no problem, as shops can transfer these programs directly to the CNC control.

Contact the Machine Tools team to learn more about the LAN Linkage function available on the TOSNUC 999 and how it can improve your shop connectivity.

Related Articles View All Machine Tools Articles

Large workpiece, but short on space? Here’s your solution.

ELK GROVE VILLAGE, IL, January 24, 2022 - Machine tools that can meet the demands of large parts and difficult to cut materials while providing increased efficiency and precision are in growing demand. Industries like oil and gas, automotive, aerospace, mi...

Read moreMachine Tool Operations Made Simple with the Manual Pendant

ELK GROVE VILLAGE, IL, January 17, 2022 - Any way that efficiency can be improved is important in the competitive world of machining. Improving efficiency not only helps cut costs, but throughput of the shop. And while there are plenty of ways to improve p...

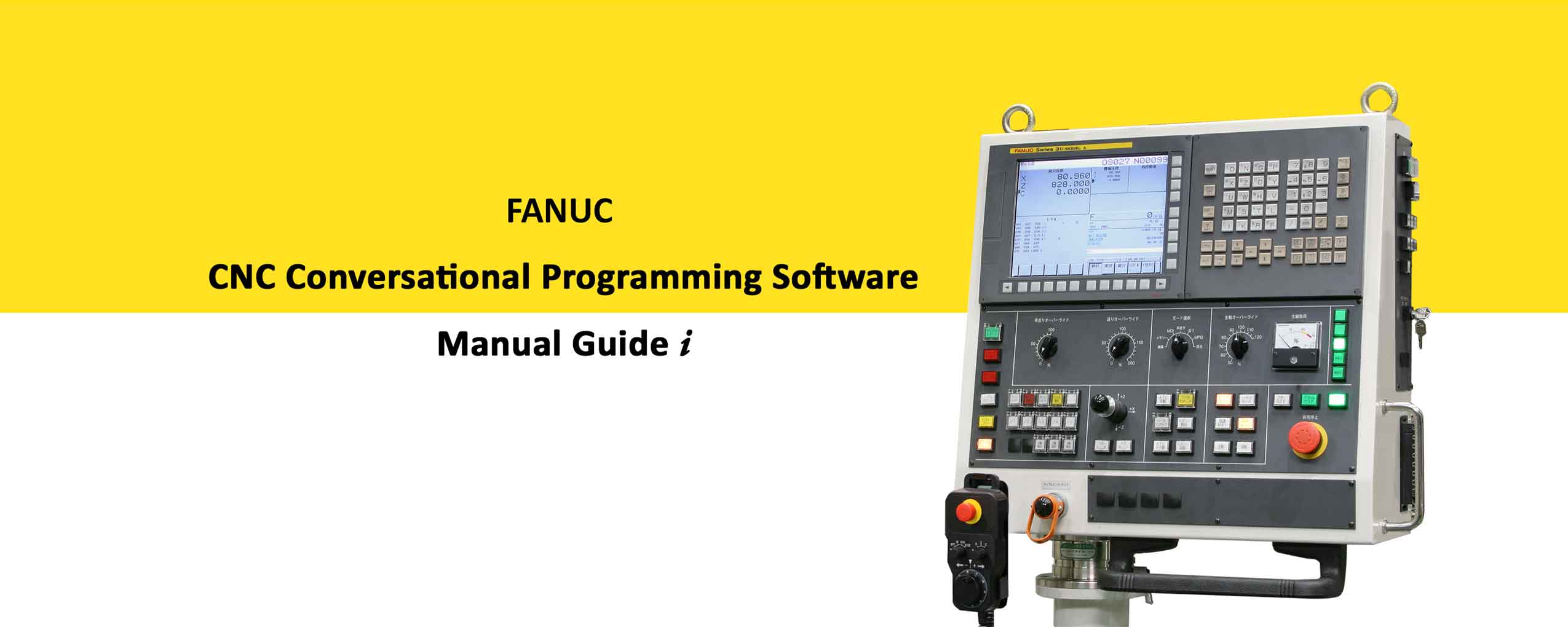

Read moreShop Floor Programming with Manual Guide i

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving production cycle times is a top shop goal to achieve this year. Conversational and/or shop floor programming software has quickly become a popular option to help meet these goals. Without knowing G-code, ...

Read moreReduce Tool Changeover Times with Convenient Access Door

ELK GROVE VILLAGE, IL, January 5, 2022 - A machine operator knows that a tool holder provides a safe critical interface between the cutting tool and the spindle of the machine. With the cutting tool mounted in the holder, it provides the stability to ensur...

Read more3 Reasons Why Financing Your Machine Tool is a Great Option

ELK GROVE VILLAGE, IL, December 29, 2021 - Most CNC shops are familiar with using their local bank or even utilizing cash on hand when making a large machine tool purchase. But have you considered the benefits of capital equipment financing? This financing...

Read moreMoving from Reactive to Proactive with Machine Tool Data Collection

ELK GROVE VILLAGE, IL, December 15, 2021 - Data is an increasingly valuable resource in the world of manufacturing. With machine tools there are hundreds of data points to pull from to get a better picture of overall performance. Collecting this data and b...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools