Improve CNC Operation Efficiency with Customized Keys on TOSNUC 999

ELK GROVE VILLAGE, IL, February 08, 2022 -

While CNC machines are excellent at doing what they are programmed to do, it is the machine operator's role to make sure they are commanded accurately. That is why being able to properly navigate the control panel plays an important role in efficiency and productivity of part manufacturing.

The TOSNUC 999 control from Shibaura Machine allows even novice CNC operators the ability to speed up display and function input and lessen the learning curve. With the Customized Keys located on the bottom of the keyboard, operators can touch a single or double key pattern in order to execute specific operations continuously instead of entering multi-keystrokes.

Quick and Continuous Operation

With many functions and displays often requiring the input of several characters, it can slow down productivity by having to enter the whole multi-character input every time. Utilizing the TOSNUC Customized Keys, operators are able to create customized shortcuts. This not only improves user experience and speeds up input of functions and displays, but it is also useful for beginners just learning the controls.

The Customized Keys shown as dice (⚀ ⚁ ⚂ ⚃ ⚄ ⚅) allow for input of a series of keystrokes to be stored. Pressing one of the dice customized keys will then execute the operation continuously. Using the cards Customized Keys (♠ ♦ ♣ ♥) allows the control to memorize a combination of CNC standard displays such as main, sub, and window. Pressing one of these keys displays the combination memorized.

Learn More

The Customized Keys is just one way the TOSNUC 999 is empowering manufacturers to improve efficiency and productivity. Contact the Machine Tool team to learn about all the features today.

Related Articles View All Machine Tools Articles

How LAN Linkage is Improving Operational Efficiency

ELK GROVE VILLAGE, IL, January 31, 2022 - When it comes to connecting a CNC machine to your network, doing so benefits the bottom line by increasing productivity and improving uptime. With local area network (LAN) connectivity, shops are able to easily sen...

Read moreLarge workpiece, but short on space? Here’s your solution.

ELK GROVE VILLAGE, IL, January 24, 2022 - Machine tools that can meet the demands of large parts and difficult to cut materials while providing increased efficiency and precision are in growing demand. Industries like oil and gas, automotive, aerospace, mi...

Read moreMachine Tool Operations Made Simple with the Manual Pendant

ELK GROVE VILLAGE, IL, January 17, 2022 - Any way that efficiency can be improved is important in the competitive world of machining. Improving efficiency not only helps cut costs, but throughput of the shop. And while there are plenty of ways to improve p...

Read moreShop Floor Programming with Manual Guide i

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving production cycle times is a top shop goal to achieve this year. Conversational and/or shop floor programming software has quickly become a popular option to help meet these goals. Without knowing G-code, ...

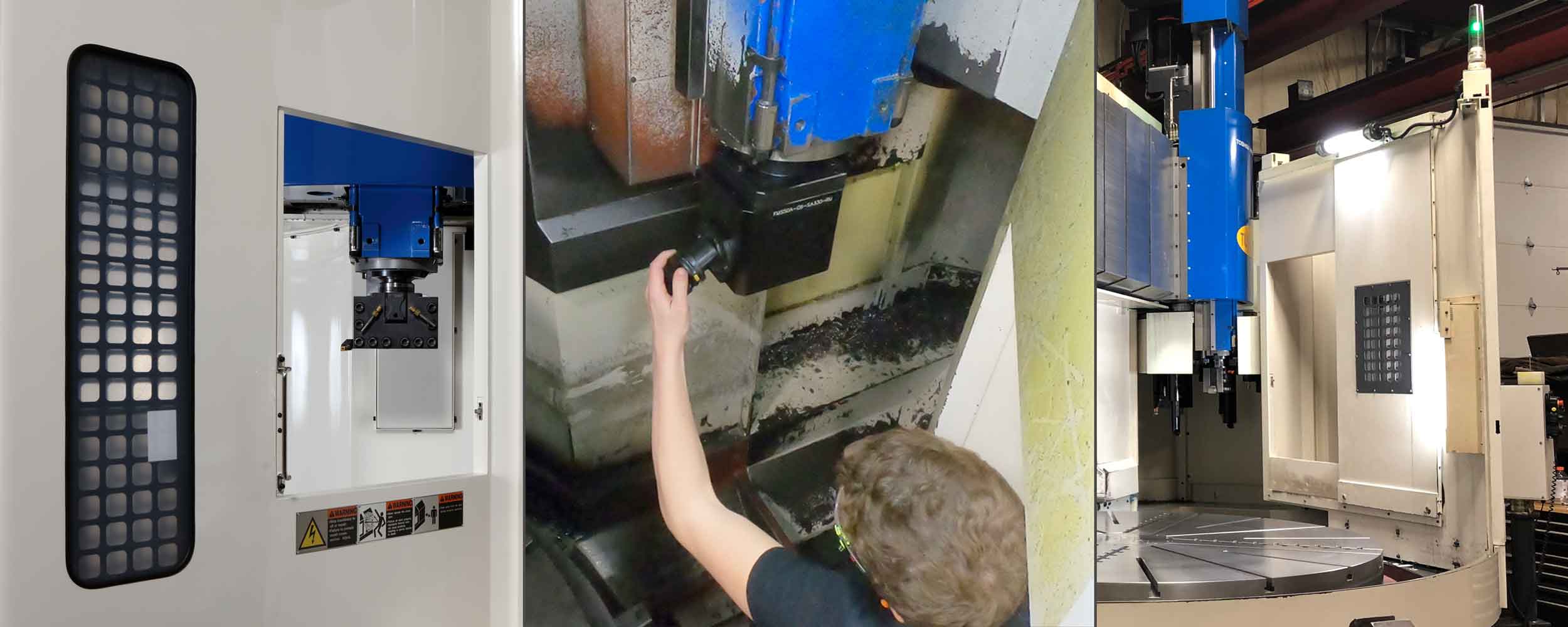

Read moreReduce Tool Changeover Times with Convenient Access Door

ELK GROVE VILLAGE, IL, January 5, 2022 - A machine operator knows that a tool holder provides a safe critical interface between the cutting tool and the spindle of the machine. With the cutting tool mounted in the holder, it provides the stability to ensur...

Read more3 Reasons Why Financing Your Machine Tool is a Great Option

ELK GROVE VILLAGE, IL, December 29, 2021 - Most CNC shops are familiar with using their local bank or even utilizing cash on hand when making a large machine tool purchase. But have you considered the benefits of capital equipment financing? This financing...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools