Moving from Reactive to Proactive with Machine Tool Data Collection

ELK GROVE VILLAGE, IL, December 15, 2021 -

Data is an increasingly valuable resource in the world of manufacturing. With machine tools there are hundreds of data points to pull from to get a better picture of overall performance. Collecting this data and being able to manage it empowers your shop's ability in better decision making which increases profitability, improves product and services, and overall customer satisfaction. But what does this all really mean?

Connectivity gives you increased visibility into your operations and allows your shop to make better business decisions. With predictive analytics, your shop is able to move away from being reactive, becoming more predictive and proactive. This affords you the ability to quickly pinpoint inefficiencies in production, but shop floor productivity is really only the tip of the iceberg.

That is why your teams need to be equipped with the right resources to pull data from the equipment and manage it. These data backed decisions will not only allow for continued success, but also improvement- becoming one of your most important assets.

The Path to Improving Data Visibility

Shibaura Machine offers modern CNC technologies that afford shops an easier way to collect and manage their data. From monitoring the status of machine operations, to predicting maintenance needs, improved real time performance data visibility and management allows for smarter decision making which positively impacts productivity and the shop's bottom line.

Being able to collect, manage, and analyze data between systems means:

- Enhanced visibility to identify roadblocks

- Better prioritization of tasks

- Ability to rapidly adapt to changing conditions

- Improved asset investment

All this adds up to improved ROI. When your shop manages and analyzes real time data with ease you can start optimizing machine productivity, implementing a preventative maintenance schedule, and in turn improving the reliability of your machine tool.

Investing in Continuous Improvement

Shibaura Machine is committed to helping shop owners and operators better understand their production operations. This means manufacturing modern CNC technologies to monitor machine operations, predict maintenance needs, and make smart decisions that positively impact productivity and ROI levels. By improving the communication flow between systems and incorporating predictive analytics your shop can move from a reactive to proactive environment.

Contact our Machine Tools team to discuss data collection and management.

Related Articles View All Machine Tools Articles

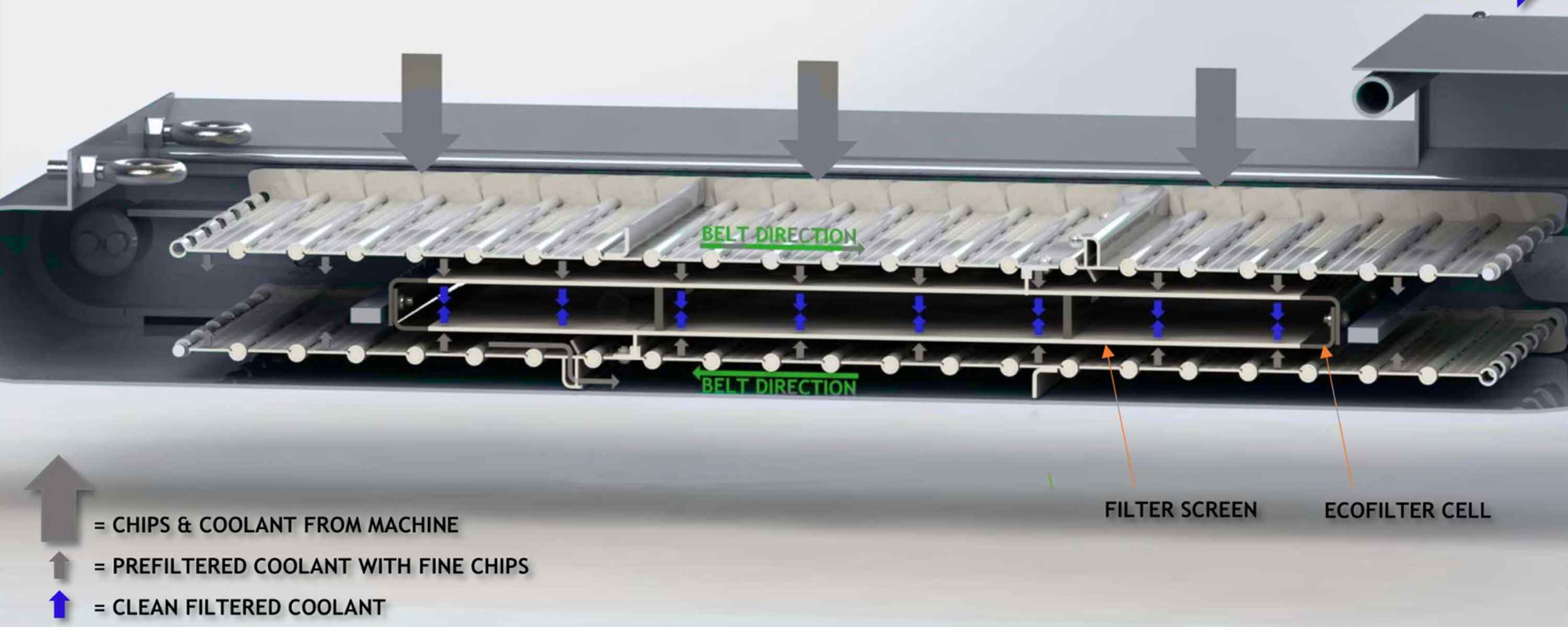

Looking to improve chip filtration on your machine tool? Consider this.

ELK GROVE VILLAGE, IL, December 8, 2021 - Maximizing machine tool output is the goal for today’s industrial manufacturing applications. Being able to machine as many quality parts in the shortest amount of time allows for higher profitability and return on...

Read moreSpotlight: Machine Tool Customer Support Team

ELK GROVE VILLAGE, IL, December 2, 2021 - When customers purchase from Shibaura Machine, they know they are getting a high-performance machine tool. Ensuring you maintain the high-performance of your investment is just as important, if not more, then the i...

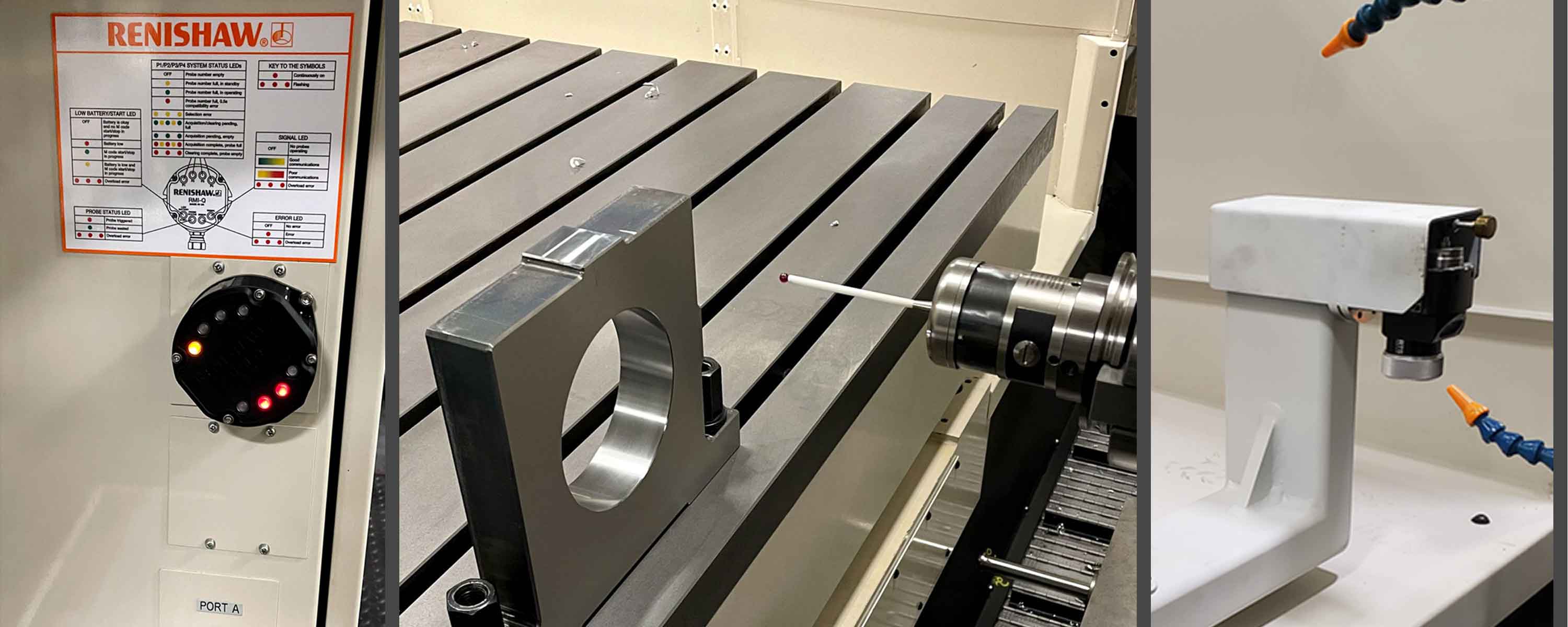

Read moreAutomated Machine Tool Health Checks Improve Productivity

ELK GROVE VILLAGE, IL, November 22, 2021 - Time is money. Being able to quickly identify problems when it comes to machine set-up, collisions, and wear can help shops save on both performance and profitability. Probing also offers both an easy and reliable...

Read moreHighlighting the Renishaw OSP60 Probe for Your Machine Tool

ELK GROVE VILLAGE, IL, November 15, 2021 - One constant in manufacturing is the need to focus on operating margins in order to remain competitive. What are the best ways to improve productivity and precision while boosting profits?Probing has been a long e...

Read moreUnderstand the Benefits of a Tool Setting Probe for Your Shibaura Machine Tool

ELK GROVE VILLAGE, IL, November 9, 2021 - Going into 2022 shops are focused on ways to improve workpiece quality, while saving time and money. One of the most efficient ways to optimize your processes from the ground up is to consider adding a tool setter....

Read moreAdding a Workpiece Inspection Probing System to Your Machine Tool Is Worth Considering

ELK GROVE VILLAGE, IL, November 2, 2021 - As machine tool automation advances, more manufacturers are looking towards the addition of a inspection probing system to help them make a bigger impact on their performance and profitability. That is why Shibaura...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools