Large workpiece, but short on space? Here’s your solution.

ELK GROVE VILLAGE, IL, January 24, 2022 -

Machine tools that can meet the demands of large parts and difficult to cut materials while providing increased efficiency and precision are in growing demand. Industries like oil and gas, automotive, aerospace, mining and construction, and more present challenges that require custom engineered fixturing to accommodate their size, weight, and shape. Many of the machines tools that are able to meet their requirements unfortunately take up a large footprint, until now.

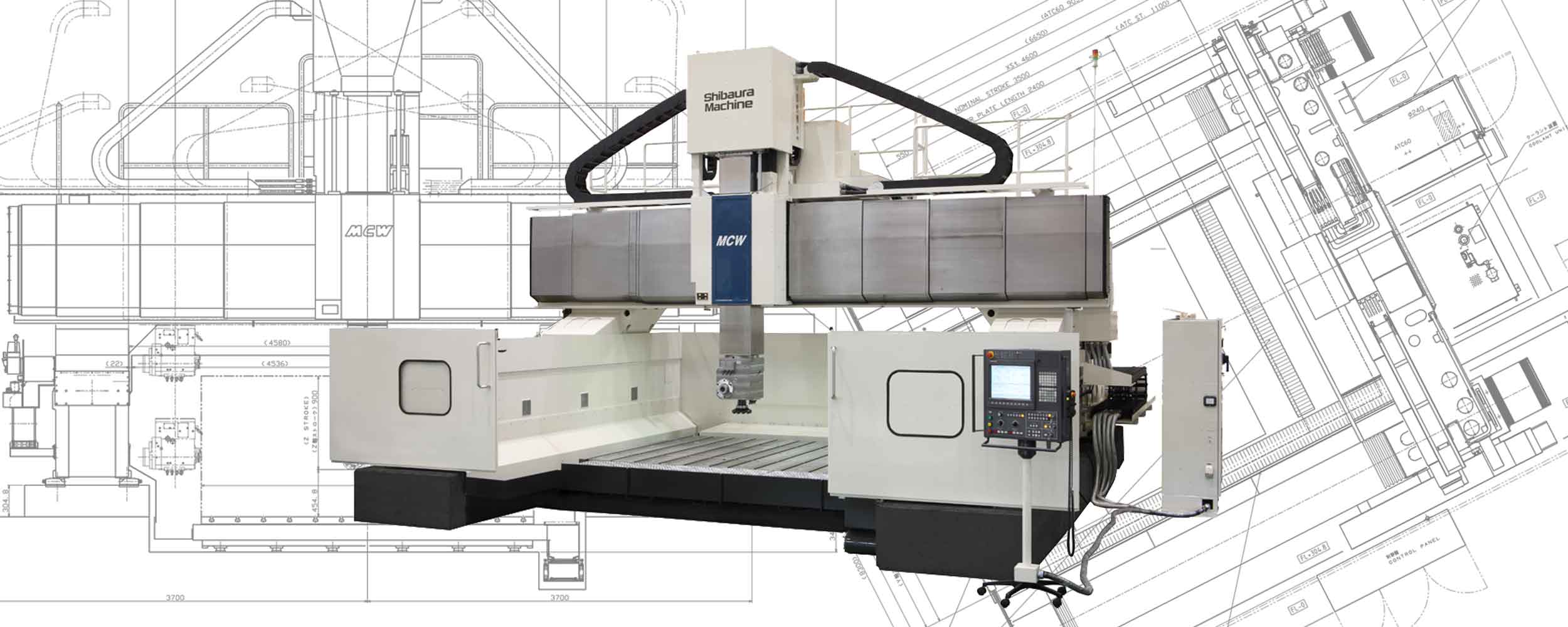

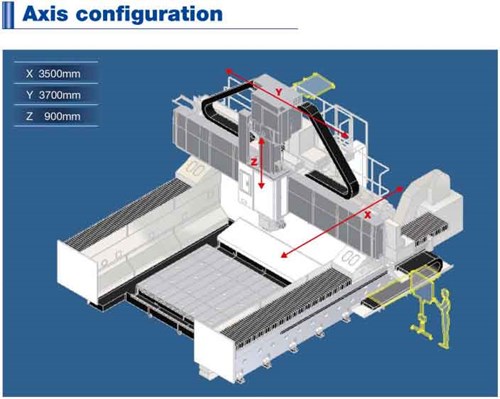

Shibaura Machine has developed an innovative new wall column type crossrail travel machine tool that is highly cost-effective, while also ensuring higher productivity and performance with a smaller footprint. The MCW series is able to process large workpieces with high accuracy and rigidity all while utilizing minimal space in the shop.

Space Saving Innovation

Instead of the moving table type machine, the innovative design of the MCW series utilizes a stationary wall column with traveling crossrail minimizing required floor space. Large and heavy workpieces are able to be machined with improved operator accessibility to the workzone.

The machine installation area is minimized to a rectangular shape which allows a significant savings in space when compared to moving table type machines. The machine layout is versatile, with several variations from the basic design that include special machining attachments and optional accessories.

All of the machine’s main components are cast in Shibaura Machine’s own foundry to guarantee the highest level of quality. To assure stable and rigid machining, the spindle is surrounded and supported by a square ram. The crossrail configuration, which travels on a wall column, is supported by two rigid and stable saddles and has a low center of gravity to assure high accuracy and rigidity.

The space saving MCW series includes the latest CNC control from Shibaura Machine which makes this the ideal machine for high speed machining and high metal removal in numerous industries. Contact the Machine Tool team to learn more about this innovation machining option.

Learn more about our MCW series.

Related Articles View All Machine Tools Articles

Machine Tool Operations Made Simple with the Manual Pendant

ELK GROVE VILLAGE, IL, January 17, 2022 - Any way that efficiency can be improved is important in the competitive world of machining. Improving efficiency not only helps cut costs, but throughput of the shop. And while there are plenty of ways to improve p...

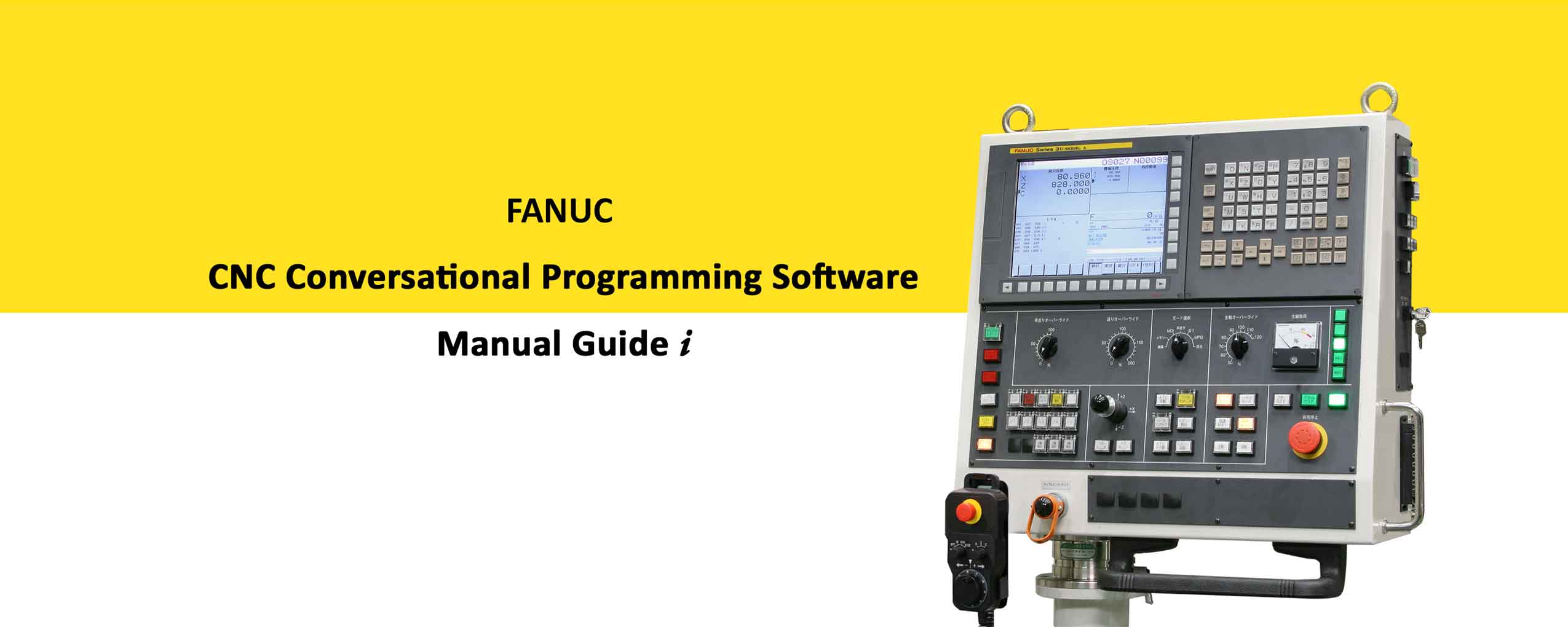

Read moreShop Floor Programming with Manual Guide i

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving production cycle times is a top shop goal to achieve this year. Conversational and/or shop floor programming software has quickly become a popular option to help meet these goals. Without knowing G-code, ...

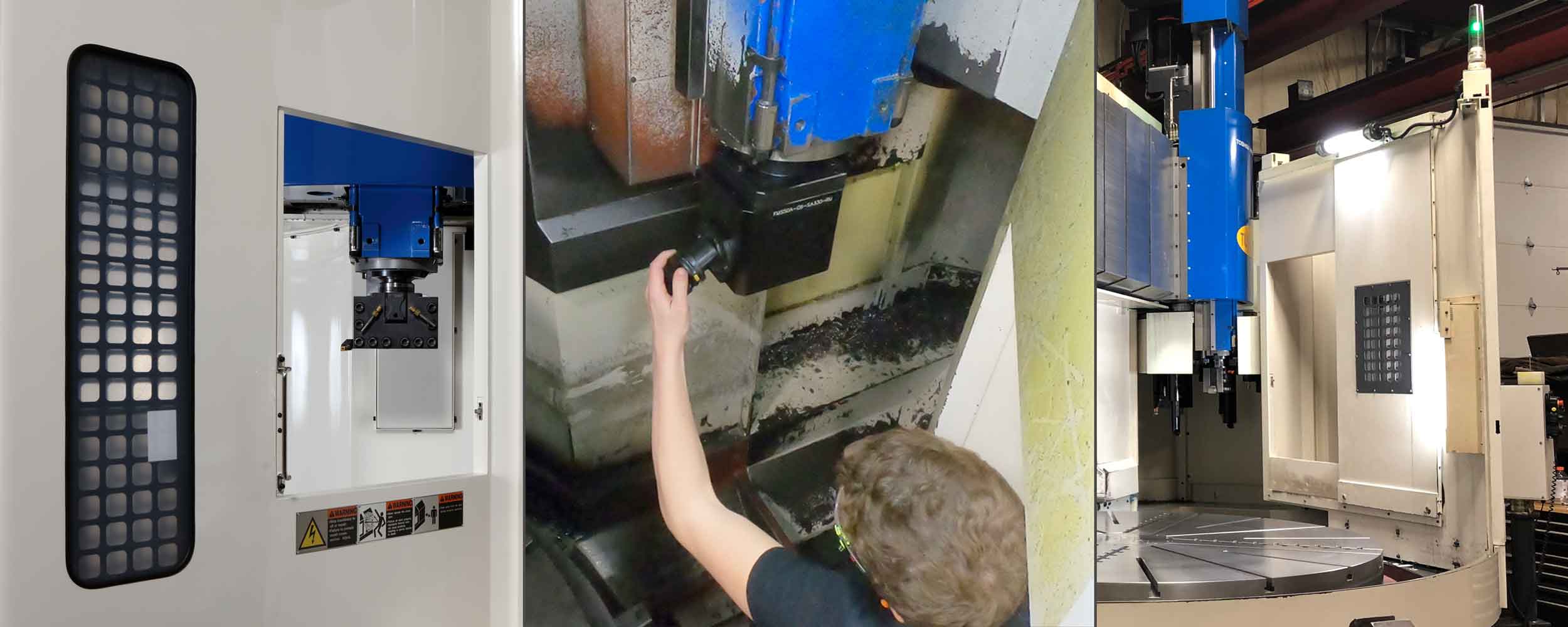

Read moreReduce Tool Changeover Times with Convenient Access Door

ELK GROVE VILLAGE, IL, January 5, 2022 - A machine operator knows that a tool holder provides a safe critical interface between the cutting tool and the spindle of the machine. With the cutting tool mounted in the holder, it provides the stability to ensur...

Read more3 Reasons Why Financing Your Machine Tool is a Great Option

ELK GROVE VILLAGE, IL, December 29, 2021 - Most CNC shops are familiar with using their local bank or even utilizing cash on hand when making a large machine tool purchase. But have you considered the benefits of capital equipment financing? This financing...

Read moreMoving from Reactive to Proactive with Machine Tool Data Collection

ELK GROVE VILLAGE, IL, December 15, 2021 - Data is an increasingly valuable resource in the world of manufacturing. With machine tools there are hundreds of data points to pull from to get a better picture of overall performance. Collecting this data and b...

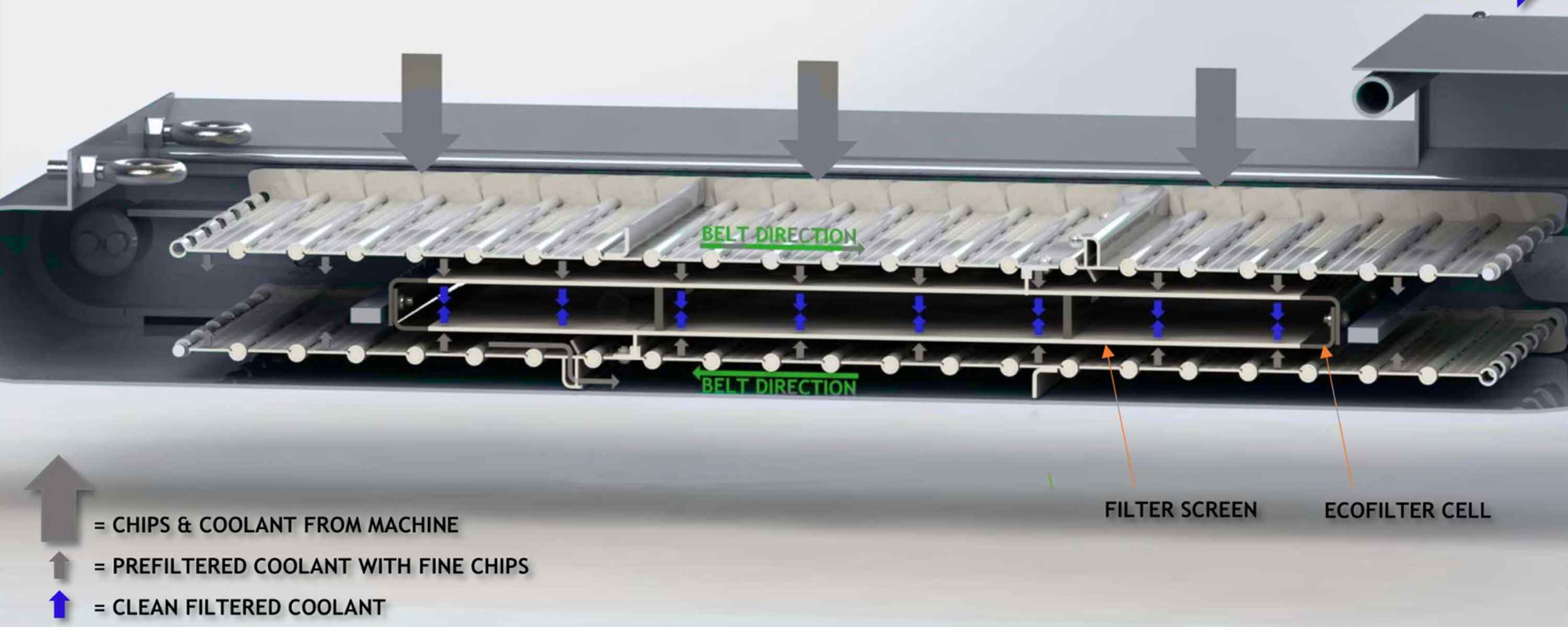

Read moreLooking to improve chip filtration on your machine tool? Consider this.

ELK GROVE VILLAGE, IL, December 8, 2021 - Maximizing machine tool output is the goal for today’s industrial manufacturing applications. Being able to machine as many quality parts in the shortest amount of time allows for higher profitability and return on...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools