Automated Machine Tool Health Checks Improve Productivity

ELK GROVE VILLAGE, IL, November 22, 2021 -

Time is money. Being able to quickly identify problems when it comes to machine set-up, collisions, and wear can help shops save on both performance and profitability. Probing also offers both an easy and reliable process for analyzing overall machine health and providing accurate data which is key to precision machining.

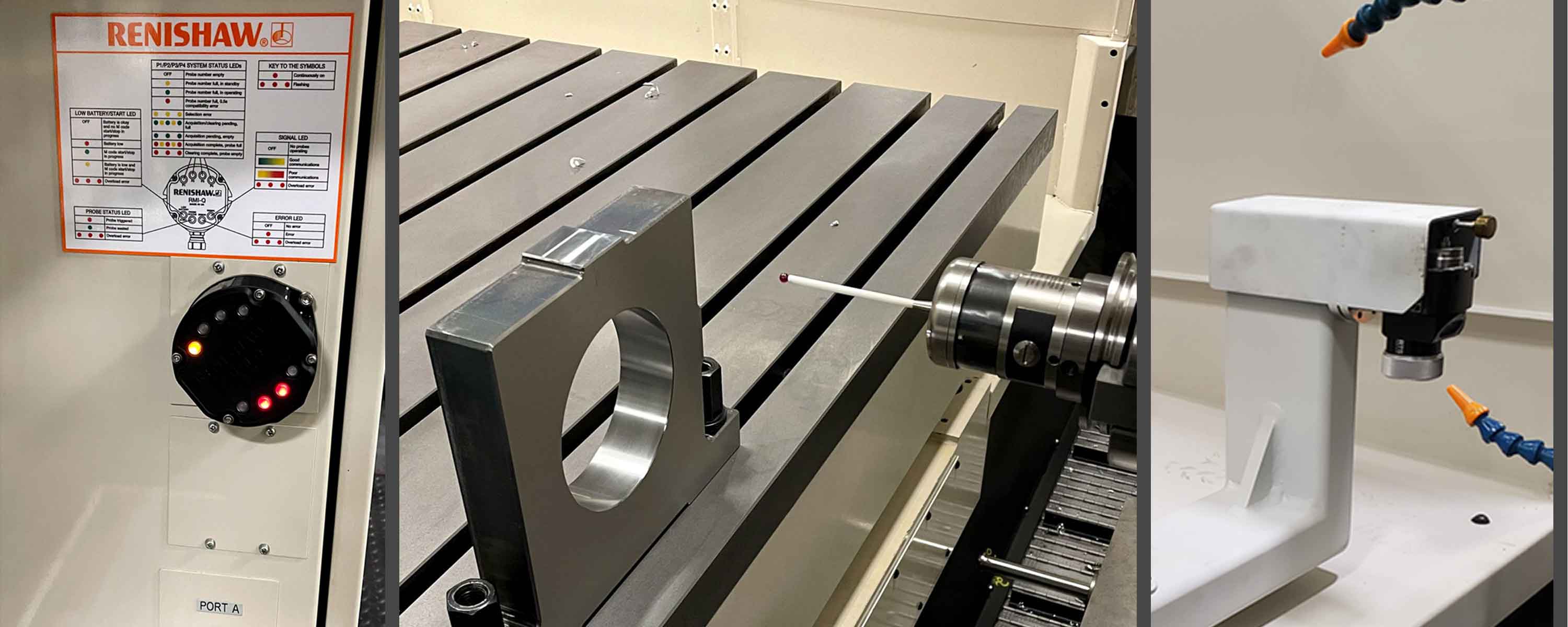

Shibaura Machine’s partnership with Metrology Resource Group (MRG) as our integrator in the installation and application assistance of the RMP60 Renishaw probing systems allow our machine tool customers the ability to cost-effectively identify and report on overall machine health that can improve process setting times and overall productivity.

Quick & Reliable Machine Tool Health Checks

Being able to increase automation and reduce human intervention allows your shop to extract more throughput from existing assets, decrease re-work, and overall reduce total cost of ownership. Automated probing routines provide accurate and repeatable test results that gather performance data from a reference artifact, and include simple and powerful analysis.

Several key capabilities of the probe when it comes to overall machine health check include:

- Utilizing probing coupled with calibration artifacts to monitor machine tool performance, repeatability, and determine process capability in order to verify the machine is capable of the required tolerances

- Automated inspection reporting to track quality presented and hard copy provided for future reference

- Taking human error and decision making out of the inspection process

- Ability to measure parts in the machine before removing them, eliminating the need to re-work parts that are not to spec, and the need for large hand gages

Ultimately, all different configurations of machine tools can benefit from probing when it comes to analyzing and reporting on overall machine health. The capabilities mentioned in this article add up to improved responsiveness, productivity, and quality of work. To learn more about our cost-effective way to analyze and report on machine performance contact us.

Related Articles View All Machine Tools Articles

Highlighting the Renishaw OSP60 Probe for Your Machine Tool

ELK GROVE VILLAGE, IL, November 15, 2021 - One constant in manufacturing is the need to focus on operating margins in order to remain competitive. What are the best ways to improve productivity and precision while boosting profits?Probing has been a long e...

Read moreUnderstand the Benefits of a Tool Setting Probe for Your Shibaura Machine Tool

ELK GROVE VILLAGE, IL, November 9, 2021 - Going into 2022 shops are focused on ways to improve workpiece quality, while saving time and money. One of the most efficient ways to optimize your processes from the ground up is to consider adding a tool setter....

Read moreAdding a Workpiece Inspection Probing System to Your Machine Tool Is Worth Considering

ELK GROVE VILLAGE, IL, November 2, 2021 - As machine tool automation advances, more manufacturers are looking towards the addition of a inspection probing system to help them make a bigger impact on their performance and profitability. That is why Shibaura...

Read moreHow Shibaura Machine Builds Quality into Every Machine Tool

ELK GROVE VILLAGE, IL, October 25, 2021 - Building a machine tool from a geometry standpoint can be equated to building a house. Just like a house needs walls to be square, floors to be flat, and structural components need to be aligned the same principles...

Read moreWhat to Consider When Calculating Machine Tool Total Cost of Ownership

ELK GROVE VILLAGE, IL, October 19, 2021 - Manufacturers everywhere are feeling the pressure to reduce operating costs. Understanding the true total cost of ownership (TCO) of your machine tool will allow you to make a more informed decision and better eval...

Read moreCNC Machine Tool Preventive Maintenance Tips

ELK GROVE VILLAGE, IL, October 11, 2021 - Optimizing machine tool performance and uptime starts with a healthy machine. Preventive maintenance not only protects your investment and improves machine tool longevity, but also keeps machining processes capable...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools