CNC Machine Tool Preventive Maintenance Tips

ELK GROVE VILLAGE, IL, October 11, 2021 -

Optimizing machine tool performance and uptime starts with a healthy machine. Preventive maintenance not only protects your investment and improves machine tool longevity, but also keeps machining processes capable.

Preventive maintenance reduces the likelihood your machine tool will have unplanned downtime. Preventive maintenance should be scheduled, controllable, and measurable. For best practice Shibaura Machine Company, America recommends reviewing your maintenance manual for a complete list of requirements.

Surrounding Manufacturing Area

Manufacturing area should be kept clean and free from cutting chips, debris, and obstacles.

Lubricants

A machine tool’s lubrication system regulates the volume of lubrication for sliding and rotating components. On a daily basis operators should fill oil reservoirs, hydraulic and spindle mist oils if necessary. Periodically, change the lubrication oil, hydraulic oil, and grease all required locations per the machine lubrication chart.

Air

Periodically you will want to assess the incoming air pressure and volume to the machine. This includes checking and verifying the air/water separator filter.

Electrical

Preventive electrical maintenance is another important part to maintaining your machine tools performance.

- Daily check

- Check that electrical cabinet fans are working

- Check that electrical cabinet door is secured and locked

- Periodic check

- Change electrical cabinet filters

- Check incoming voltage is proper and stable

- Check that contaminants are not getting into the electrical cabinet

- Clean debris from electrical components

Ways and Ball Screws

Preventive maintenance around the ways and ball screws can help protect costly damage from occurring.

Pull back way covers and inspect ways:

- Check for marks or damage

- Check that each way has a sheen of oil on it from the way oiler

- Check that gibs and keeper plates are tight and oil lines are properly attached

- Inspect all oil lines to ensure they are connected and not kinked

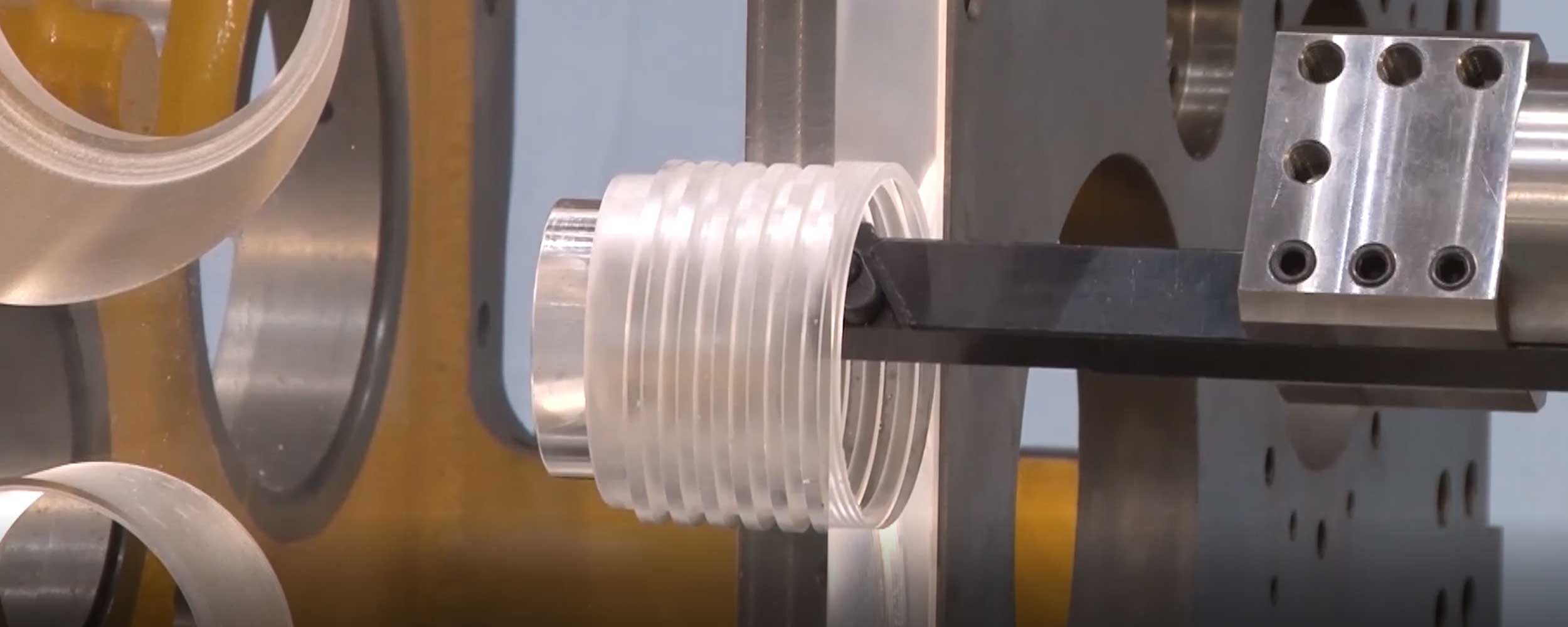

Inspect the ball screws:

- Check that ball screw has proper lubrication

- Check that there is no damage or scoring on the ball screw

- Check that all lubrication lines are connected and not kinked

- Check to verify that end nut is tight

- Check to ensure motor coupling is tight

Coolant

Your operators will want to make sure to clean coolant filter and empty the debris catch baskets on a daily basis. Tasks like draining the coolant system, cleaning reservoir tanks and screens, and replacing the coolant filter can take place periodically depending on the material and cutting conditions of your machine tool.

Level and accuracy

A square and level machine offers optimum machine performance. Make sure your maintenance team is checking and adjusting machine level as necessary to maintain machine accuracy.

Your Preventive Maintenance Team

Performing preventive maintenance will bring your shop peace of mind that machine tools are operating at peak performance. This checklist can be performed in house or by a field service technician. Shibaura Machine Company, America has a top-tier field service team trained to support you on your CNC machine tool preventive maintenance needs. Contact us at (888) 593-1616 or submit an online service request to learn more about available support options.

For more information contact MT-SVC@shibaura-machine.com

Related Articles View All Machine Tools Articles

Shibaura Machine’s Checklist for a Successful Machine Tool Installation

ELK GROVE VILLAGE, IL, October 04, 2021 - High quality machine tools will last for years, so for many shops it may have been awhile since their last installation. The prep before and set-up of your CNC machine is important to make sure it can do its job pr...

Read moreWisconsin Manufacturing & Technology Show booth #604 from Oct. 5th - 7th in West Allis, Wisconsin

ELK GROVE VILLAGE, IL, September 27, 2021 - From design to delivery, manufacturers are looking to leverage new approaches and technologies in order to uncover opportunities for growth in the market. At Shibaura Machine, we work with our customers in co-cre...

Read moreShibaura Machine’s Quill Machining Strategy Provides Performance and Cost Advantage

ELK GROVE VILLAGE, IL, September 21, 2021 - When it comes to obtaining the highest level of profitability in CNC shops, many go on the hunt for different technologies, tools, and processes. Often overlooked is quill (bar) style horizontal machining. Quills...

Read moreEnhance Versatility with Shibaura Machine’s Orbit Boring Function

ELK GROVE VILLAGE, IL, September 14, 2021 - Whether your shop has high speed finishing or heavy duty machining applications, orbit boring is worth a consideration. With Shibaura Machine’s orbit boring function you can not only remove metal faster, but it i...

Read moreShibaura Machine Discusses Opportunities to Improve Machine Tool OEE

ELK GROVE VILLAGE, IL, September 7, 2021 - How many times is your machine “getting it right the first time” compared to what it should be producing in a set time? This is the basis of determining Overall Equipment Effectiveness (OEE), a key performance ind...

Read moreOptimize Innovation with Siemens Realize Live Virtual Event

ELK GROVE VILLAGE, IL, August 31, 2021 - Every industry comes with its own set of unique manufacturing requirements. Whether it be complex shapes, large part sizes, or the use of exotic metals, having partners that provide specific solutions to meet those ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools