Wisconsin Manufacturing & Technology Show booth #604 from Oct. 5th - 7th in West Allis, Wisconsin

ELK GROVE VILLAGE, IL, September 27, 2021 -

From design to delivery, manufacturers are looking to leverage new approaches and technologies in order to uncover opportunities for growth in the market. At Shibaura Machine, we work with our customers in co-creation of our machines to respond with innovations to help them maintain a competitive edge. Sourcing all major casting for machines from our own foundry in Japan further ensures the necessary machine casting quality required in the machines and has made Shibaura Machine a world leader in machine tool design.

See our latest design of the compact horizontal table type boring and milling machine at the Wisconsin Manufacturing & Technology Show (WIMTS) from Oct. 5th – 7th in Wisconsin State Fair Park - West Allis, WI. The 5th generation of this design offers a modern and compact machine solution.

Efficient and Effective

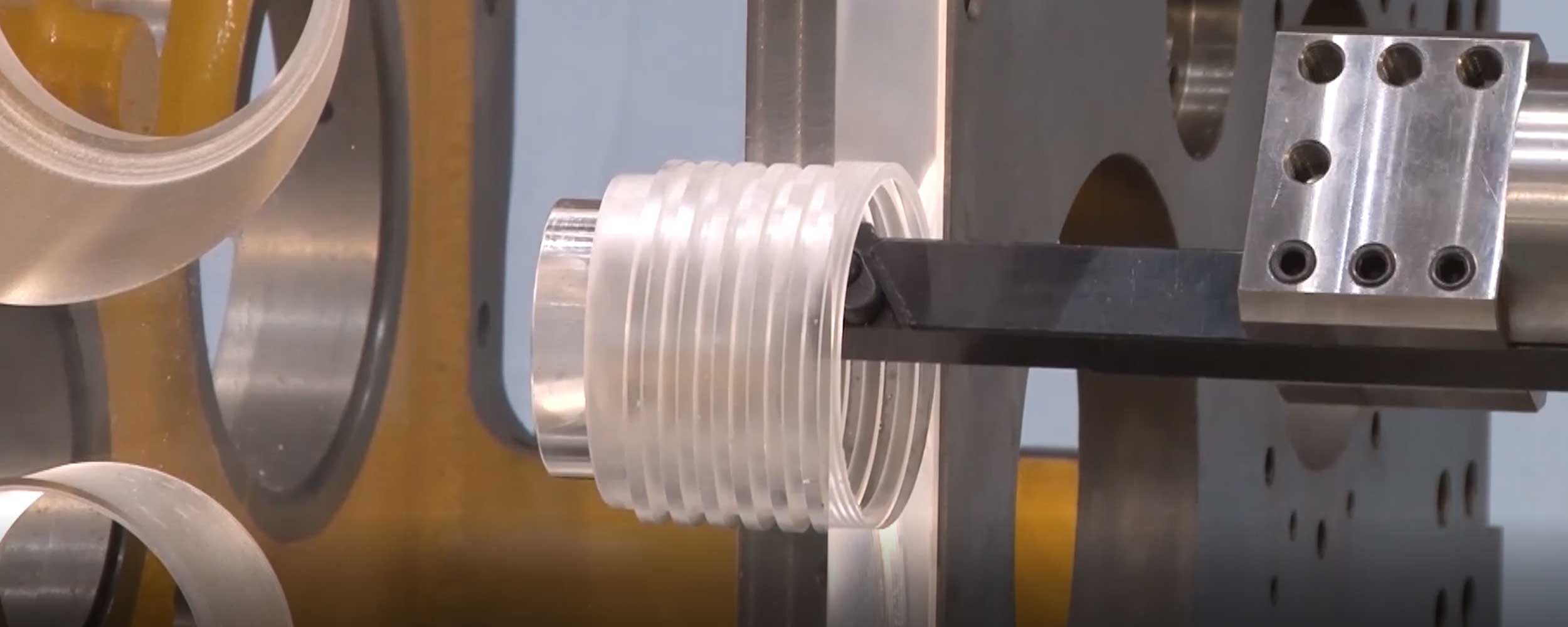

The Shibaura Machine BTD-100.R12 is a compact horizontal table type boring and milling machine that is able to hold tight tolerances and is highly productive. The working table is 1000mm x 1200mm with a 5500 lbs. weight capacity and is equipped with a 100mm diameter quill, 350mm of quill travel, designed for powerful cutting. Delivering up to 3000 rpm and 40HP, it also features workpiece probing (optional), twin ball screws on the Y axes, 50 taper tooling interface, and 30 position automatic tool charger. The TOSNUC 999 CNC control comes standard and offers a full teach command which allows operation from MDI to Auto mode in a single command.

Come see the BTD-100.R12 horizontal table type boring and milling machine in action at the Wisconsin Manufacturing & Technology Show (WIMTS)

October 5, 2021: 9am – 5pm

October 6, 2021: 9am – 5pm

October 7, 2021: 9am – 3pm

or contact our team for more information.

Related Articles View All Machine Tools Articles

Shibaura Machine’s Quill Machining Strategy Provides Performance and Cost Advantage

ELK GROVE VILLAGE, IL, September 21, 2021 - When it comes to obtaining the highest level of profitability in CNC shops, many go on the hunt for different technologies, tools, and processes. Often overlooked is quill (bar) style horizontal machining. Quills...

Read moreEnhance Versatility with Shibaura Machine’s Orbit Boring Function

ELK GROVE VILLAGE, IL, September 14, 2021 - Whether your shop has high speed finishing or heavy duty machining applications, orbit boring is worth a consideration. With Shibaura Machine’s orbit boring function you can not only remove metal faster, but it i...

Read moreShibaura Machine Discusses Opportunities to Improve Machine Tool OEE

ELK GROVE VILLAGE, IL, September 7, 2021 - How many times is your machine “getting it right the first time” compared to what it should be producing in a set time? This is the basis of determining Overall Equipment Effectiveness (OEE), a key performance ind...

Read moreOptimize Innovation with Siemens Realize Live Virtual Event

ELK GROVE VILLAGE, IL, August 31, 2021 - Every industry comes with its own set of unique manufacturing requirements. Whether it be complex shapes, large part sizes, or the use of exotic metals, having partners that provide specific solutions to meet those ...

Read moreOptimize Metal Removal Rates with a High Efficiency Machining Strategy

ELK GROVE VILLAGE, IL, August 23, 2021 - Efficiency is a key advantage when it comes to being a competitive shop. In addition the ability to provide speed and precision with a machine from Shibaura Machine is a huge advantage when attempting to maximize Me...

Read moreHow Shibaura Machine Vertical Turning Lathe Optimize Metal Removal Rates

ELK GROVE VILLAGE, IL, August 17, 2021 - Cutting optimization is a key aspect to a more productive machine and competitive foundation. But as many machinists will tell you there are many challenges when it comes to achieving optimal metal removal during t...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools