Optimize Metal Removal Rates with a High Efficiency Machining Strategy

ELK GROVE VILLAGE, IL, August 23, 2021 -

Efficiency is a key advantage when it comes to being a competitive shop. In addition the ability to provide speed and precision with a machine from Shibaura Machine is a huge advantage when attempting to maximize Metal Removal Rates (MRR) in even the most difficult to machine materials in today’s market.

Whether you are competing for jobs in the aerospace, medical, automotive, semi-conductor or industrial market a High Efficiency Milling (HEM) machining strategy is worth consideration. The HEM strategy is accomplished by increasing the axial depth of cut and reducing radial depth of the cut, utilization of smaller diameter tools with increased number of flutes, and running at higher spindle speeds and feed rates. By following the HEM strategy your machining process will show significantly higher Metal Removal Rates (MRR).

Does a HEM Machining Strategy Make Sense for Your Shop?

While removing metal quickly is important, your shop also needs to ensure accuracy. Consider the shape and complexity of the part, machine capabilities, part features and programming, among other factors when it comes to deciding on the best strategy for increasing productivity. To capitalize on a HEM strategy you will want to consider the following attributes of implementation when compared against a conventional machining strategy:

- CNC Control will need a higher processor speed to handle significantly more lines of program data

- End mills with higher number of flutes

- Higher quality tool holders with tighter Total Indicated Reading (TIR) should be considered

- Rigid workpiece fixture design with strategic fixture clamp locations

- Machining technique with smaller tool radial stepover will need to be implemented

- CAM system with a dynamic tool path option to support HEM

HEM offers an optimized High-Speed and High-Efficiency Machining strategy that will continue to grow in popularity and create a true competitive advantage for shops that are able to implement it at appropriate times. Let our team help you implement a HEM machining strategy on your next Shibaura Milling Machine.

Contact the CNC Machine Tool team to learn more at MT-Sales@shibaura-machine.com.

Learn more about our machine models.

Related Articles View All Machine Tools Articles

How Shibaura Machine Vertical Turning Lathe Optimize Metal Removal Rates

ELK GROVE VILLAGE, IL, August 17, 2021 - Cutting optimization is a key aspect to a more productive machine and competitive foundation. But as many machinists will tell you there are many challenges when it comes to achieving optimal metal removal during t...

Read moreHigh Performance Turning Machines: Uncomplicated, Efficient, Cost-Effective

ELK GROVE VILLAGE, IL, August 10, 2021 - For many machine shops it might feel like you are producing parts just fine with your existing equipment. To a certain extent, you are. But in order to gain an advantage, manufacturers must reemphasize profitability...

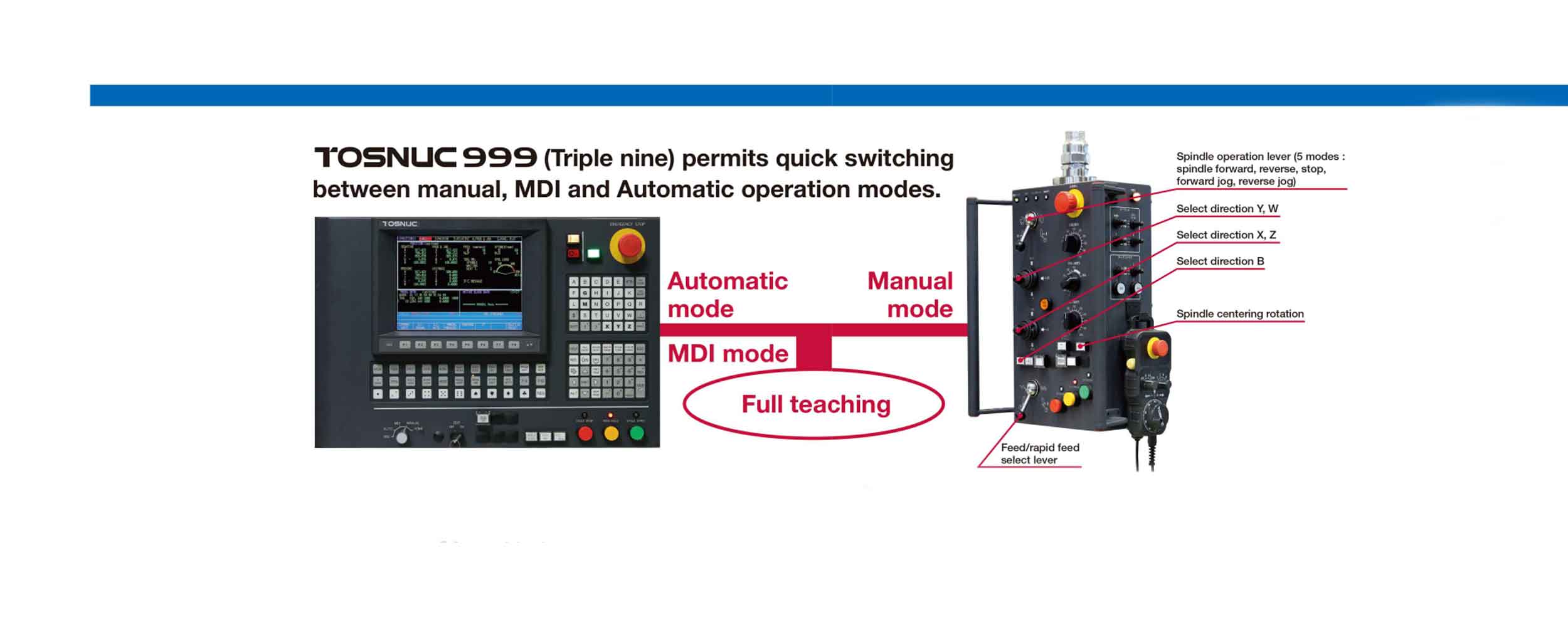

Read moreShibaura Machine Makes Transitioning from Manual to CNC Machining Simple

ELK GROVE VILLAGE, IL, August 3, 2021 - Transitioning from a manual machine control to a CNC machine can prove challenging even for the most experienced machinist. However, the access CNC gives to new markets through its capabilities to offer longer runs a...

Read moreShibaura Machine Combines the Power of Turning/Milling and Boring Into One

ELK GROVE VILLAGE, IL, July 28, 2021 - The American manufacturing industry is changing. Automation and the ability to multi-task is quickly becoming a valuable tool for factories to achieve growth due to a declining workforce and remain competitive with th...

Read moreMulti-Surface Machining Improves Efficiency and Productivity

ELK GROVE VILLAGE, IL, July 20, 2021 - Shibaura Machine is making it simple to adopt a 5 (face) sided and/or 5-axis positioning machining strategy with our double column/bridge machines. Switching to 5-Sided or 5-Axis Machining While traditional vertical 3...

Read moreShibaura Machine Horizontal Spindle Quill Machines Bring Power and Versatility to Shop Floors

ELK GROVE VILLAGE, IL, July 12, 2021 - Spindles continue to play an important role in a fast production space. Horizontal spindle quill machines allow shops to take on complex cutting jobs and also combine the structural stability and geometric precision f...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools