Enhance Versatility with Shibaura Machine’s Orbit Boring Function

ELK GROVE VILLAGE, IL, September 14, 2021 -

Whether your shop has high speed finishing or heavy duty machining applications, orbit boring is worth a consideration. With Shibaura Machine’s orbit boring function you can not only remove metal faster, but it is well suited for large and complex shapes.

Optimize Productivity and Profitability

The orbit boring function operates by leveraging Shibaura Machine’s mission to manufacture solutions that provide optimum productivity and profitability for our customers.

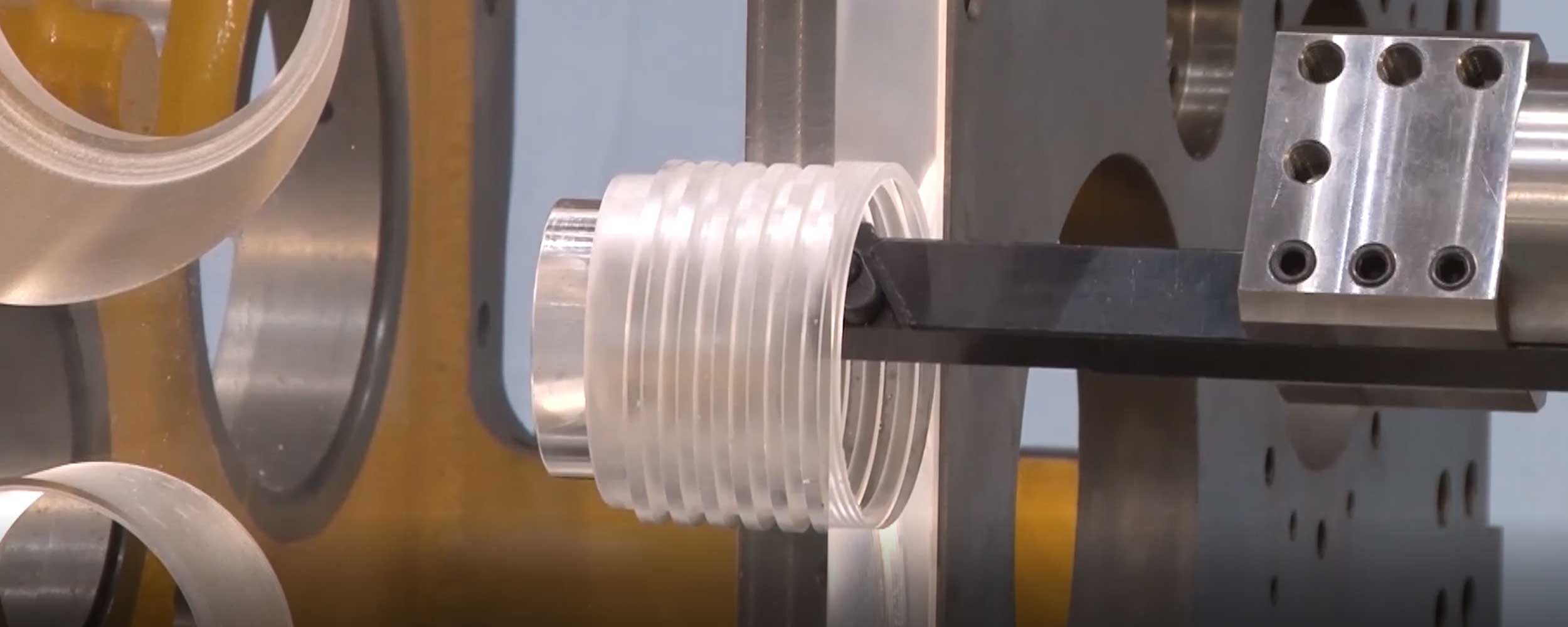

Orbital boring controls the spindle so that the spindle tool can always turn the direction of arc radius (normal direction) during circular interpolation with x-axes and y-axes. When a program for the z-x plane is executed under this condition, profile machining is performed (turning). In other words, in the turning mode function the machine spindle replaces the x-y circular axes movement and the boring is executed during the turning operation according to the turning program (z-x). With the orbit boring function it is also possible to replace the x-y circular movement with elliptical movement if the surface profile requires.

The orbit boring function enhances the use of the machine and eliminates the need to purchase additional components or a special-purpose machine. It is suitable for flange surface, groove, taper hole, tapered boss, spherical hole, spherical boss and elliptical surface cutting applications.

One Machine, Many Possibilities

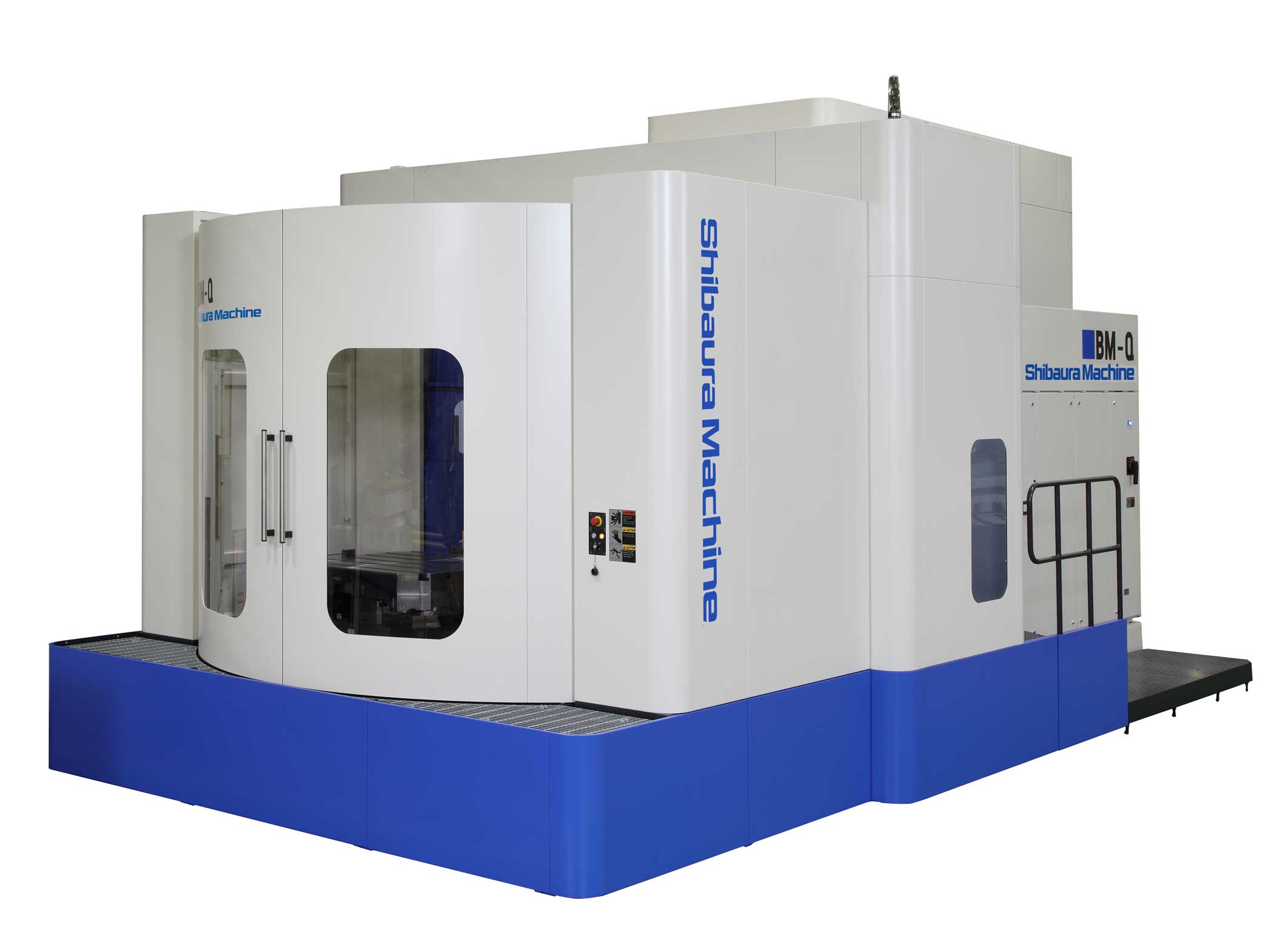

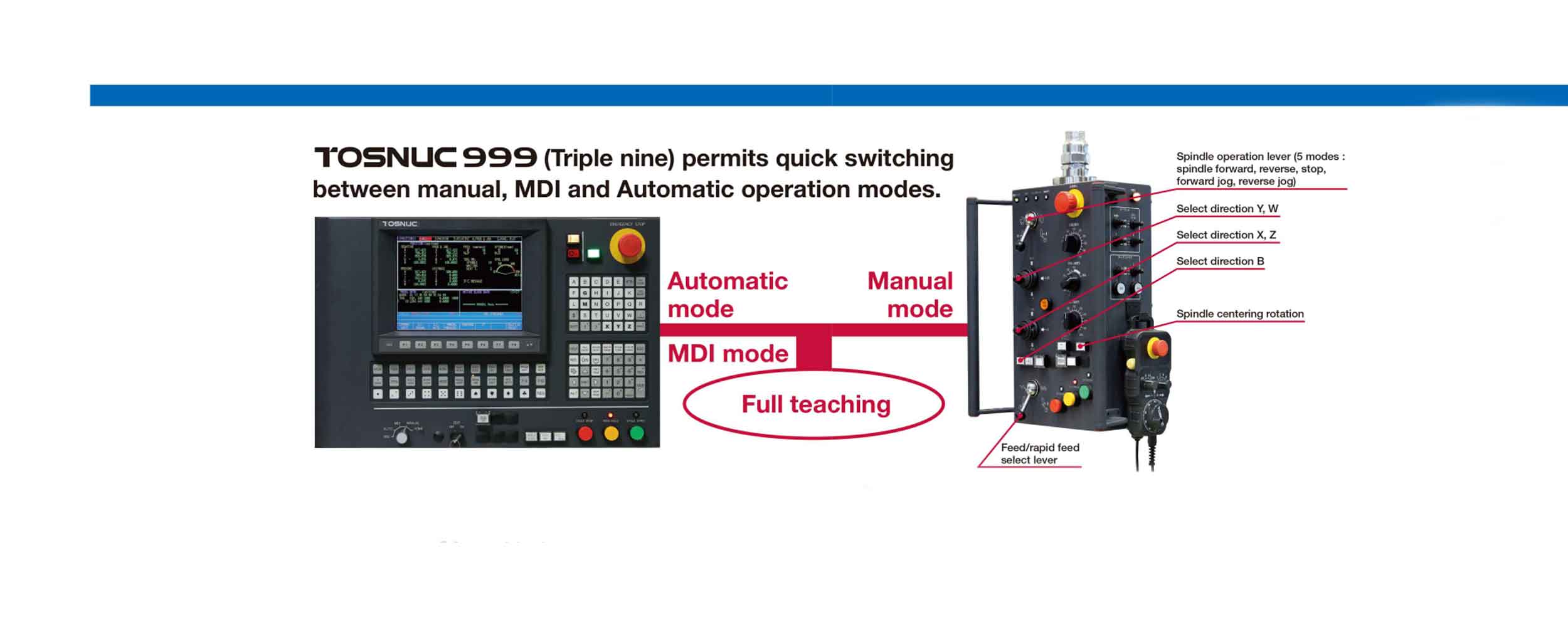

The orbit boring function is available on the Shibaura Machine BM-1000Q horizontal machining centers with the latest TOSNUC CNC control. Contact the Machine Tool team to learn more.

MT-Sales@shibaura-machine.com.

Related Articles View All Machine Tools Articles

Shibaura Machine Discusses Opportunities to Improve Machine Tool OEE

ELK GROVE VILLAGE, IL, September 7, 2021 - How many times is your machine “getting it right the first time” compared to what it should be producing in a set time? This is the basis of determining Overall Equipment Effectiveness (OEE), a key performance ind...

Read moreOptimize Innovation with Siemens Realize Live Virtual Event

ELK GROVE VILLAGE, IL, August 31, 2021 - Every industry comes with its own set of unique manufacturing requirements. Whether it be complex shapes, large part sizes, or the use of exotic metals, having partners that provide specific solutions to meet those ...

Read moreOptimize Metal Removal Rates with a High Efficiency Machining Strategy

ELK GROVE VILLAGE, IL, August 23, 2021 - Efficiency is a key advantage when it comes to being a competitive shop. In addition the ability to provide speed and precision with a machine from Shibaura Machine is a huge advantage when attempting to maximize Me...

Read moreHow Shibaura Machine Vertical Turning Lathe Optimize Metal Removal Rates

ELK GROVE VILLAGE, IL, August 17, 2021 - Cutting optimization is a key aspect to a more productive machine and competitive foundation. But as many machinists will tell you there are many challenges when it comes to achieving optimal metal removal during t...

Read moreHigh Performance Turning Machines: Uncomplicated, Efficient, Cost-Effective

ELK GROVE VILLAGE, IL, August 10, 2021 - For many machine shops it might feel like you are producing parts just fine with your existing equipment. To a certain extent, you are. But in order to gain an advantage, manufacturers must reemphasize profitability...

Read moreShibaura Machine Makes Transitioning from Manual to CNC Machining Simple

ELK GROVE VILLAGE, IL, August 3, 2021 - Transitioning from a manual machine control to a CNC machine can prove challenging even for the most experienced machinist. However, the access CNC gives to new markets through its capabilities to offer longer runs a...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools