The Rise of All Electric LSR Injection Molding Machines

ELK GROVE VILLAGE, IL, September 29, 2023 - Are you looking for a way to produce high-quality, intricate silicone components at unprecedented speeds? You're not alone. In a manufacturing landscape where efficiency, versatility, and precision are pivotal, the technology you choose can make or break your competitive edge.

As industries such as medical, automotive, and consumer electronics demand complex and high-quality silicone parts, factories are turning to advanced Liquid Silicone Rubber (LSR) injection molding machines to meet these needs. LSR machines use high temperature molds and lower injection pressures to quickly and efficiently produce detailed silicone parts with complex geometries. This makes them an ideal solution for industries that need high-quality parts in a short amount of time. As the demand for complex silicone parts increases, so does the need for advanced all-electric LSR injection molding machines.

The Four Cornerstones of All-Electric LSR Machine Innovation

All-electric LSR machines are like a Swiss Army knife of manufacturing, with everything you need to get the job done and a variety of tools to help you along the way. As you consider the challenges and demands of manufacturing intricate silicone parts, these machines come with a variety of benefits that cater to a range of industrial needs.

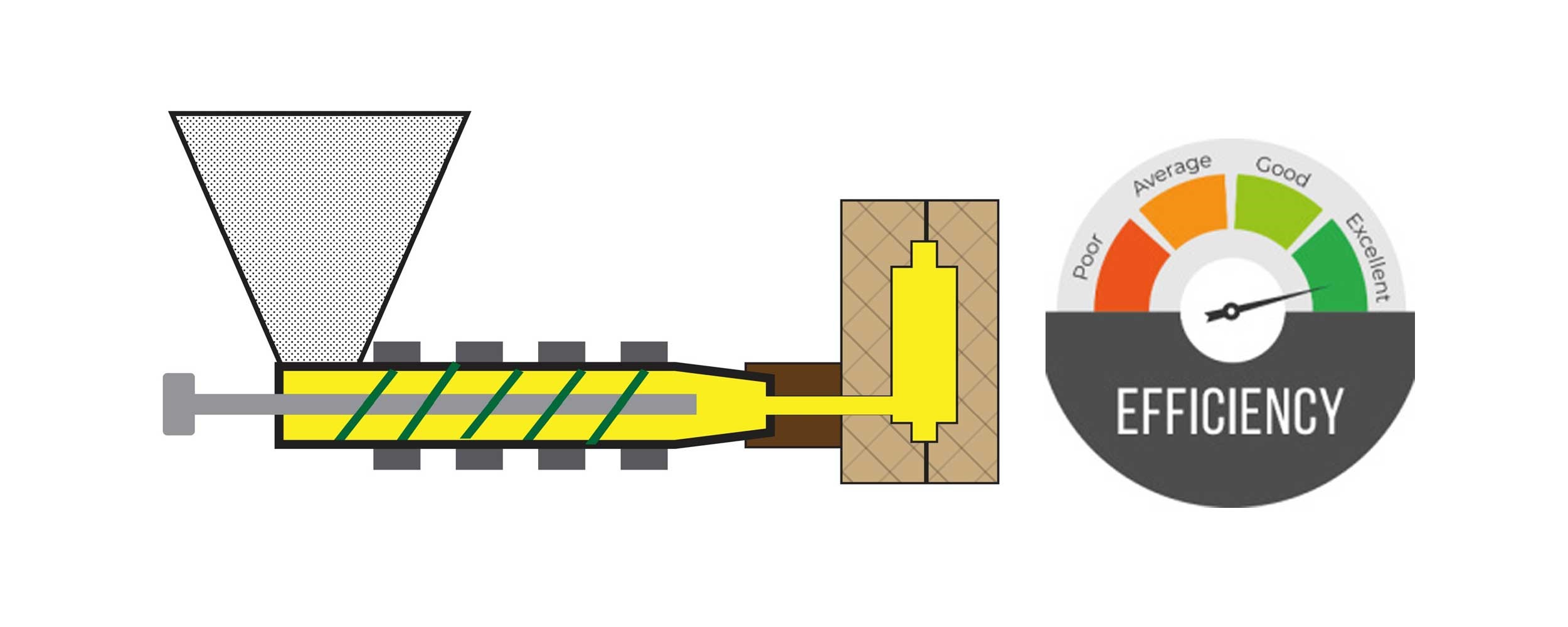

1. Efficiency

One of the most obvious benefits of all-electric LSR injection molding machines is the speed and efficiency at which they produce high-quality silicone parts which minimizes cycle times, increasing productivity. Take Shibaura Machine’s all-electric LSR for example, which can cut traditional cycle times substantially.

These machines also have the ability to adapt on-the-fly with the Quick Release LSR Barrel. This provides seamless, efficient transitions between different materials and projects. For instance, say your team has just finished a production run of specialized silicone gaskets. Now, you need to switch to medical-grade silicone tubing. Leveraging this capability means fewer delays and a more agile response to diverse manufacturing demands.

2. Precision

All-electric LSR machines can produce intricate and complex shapes with exceptional precision. This makes them ideal for a range of industries that require highly specialized silicone components, from medical devices to automotive parts.

Shibaura’s all-electric LSR machine further enhances precision by featuring four standard zones of mold heaters equipped with K-type thermocouples and a barrel cooling cast aluminum jacket with stainless steel tubing. This ensures exceptional thermal stability and real-time barrel temperature monitoring, allowing for immediate adjustments as needed.

3. Reduced Downtime

The technology is engineered to handle high-volume production with minimal maintenance, ensuring long-term factory reliability. With fewer components and no hydraulics to maintain, Shibaura Machine's all-electric LSR injection molding machine is focused on efficiency and minimizing downtime.

For instance, Shibaura’s all-electric injection molding machine eliminates the time-consuming recalibrations often required by hydraulic systems making for quick and seamless transitions.

4. Quality

The precision and repeatability of Shibaura’s all-electric LSR injection molding machines dramatically reduce manual labor, minimizing human error and elevating product quality. Features like the 6-zone cooling water manifold allow for fine-tuning material blend viscosity, a critical element for achieving superior part quality. Coupled with intelligent operations such as the "motion/no motion" feature, these machines offer unparalleled reliability and precision, important to industries like medical devices, aerospace, and automotive.

In contrast to hydraulic machines, which can show inconsistencies in pressure and require manual adjustments, all-electric machines specialize in executing intricate designs and adhering to tight tolerances, making them indispensable for sectors that demand the highest quality.

One Machine, Limitless Possibilities

Whether your manufacturing is focused on a specific industry or the types of parts you're required to produce vary from day to day, your operation's efficiency and quality are under constant observation. Offering unparalleled versatility, Shibaura Machine’s All-Electric Injection Molding Machine with fully integrated LSR technology allows manufacturers to switch between standard thermo-plastic and silicone-based materials as needed,

Shibaura's All-Electric Injection Molding Machine is not just a piece of equipment—it's a long-term partner in your manufacturing success. Whether you're tackling jobs in the medical, automotive, or electronics industry, these machines offer the capabilities you need to meet stringent quality requirements and efficiently grow your operations.

To elevate your manufacturing capabilities, contact our Injection Molding Team today.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Improve Your Injection Molding Process with Barrel Temperature Shift Mode

ELK GROVE VILLAGE, IL, August 23, 2023 - To ensure optimal product quality, consistency, and operational efficiency, precise temperature control plays a critical role in the injection molding process. One essential feature that can significantly impact inj...

Read moreMastering Material Changeovers in Injection Molding

ELK GROVE VILLAGE, IL, August 8, 2023 - Optimizing efficiency and minimizing costs are crucial to success in the fast-paced world of injection molding. However, one aspect that often poses difficulties for molders is the purging process. The traditional me...

Read morePartnering for Success: Shibaura Machine's Technical Sales Support Services

ELK GROVE VILLAGE, IL, July 20, 2023 - As the manufacturing landscape continues to evolve, having a reliable technical sales support team becomes increasingly important. With inefficiencies in injection molding processes translating into financial losses, ...

Read moreInvest in Your Success: Shibaura Machine's Training Programs for Injection Molding Professionals

ELK GROVE VILLAGE, IL, July 5, 2023 - When it comes to injection molding, having a well-trained team is crucial for maximizing machine performance and achieving optimal results. Training ensures that all personnel understand not only the machine's capabili...

Read moreAchieving Injection Molding Excellence with Integrated Auxiliary Equipment

ELK GROVE VILLAGE, IL, June 21, 2023 - Staying ahead of the competition in manufacturing requires adopting innovative solutions that enhance productivity and efficiency. Auxiliary equipment offers a way to enable precise and automated handling of materials...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools