Easily Transition to Multi-Shot Molding with Shibaura Machine

ELK GROVE VILLAGE, IL, September 13, 2023 - Two-shot molding has long captured manufacturers' interest for its ability to produce complex, multi-material components in a single cycle. With two-shot molding, designs that were once considered too intricate or costly to manufacture can now be realized. In an era where products are expected to do more, from smart automotive components to multifunctional medical devices, it allows for the integration of multiple features into a single component, enhancing the component's functionality.

Curious how this technology could fit into your production line? This article will explore some practical examples of incorporating two-shot molding into your operations and how manufacturers can implement the technology with Shibaura Machine without a massive overhaul.

Elimination of Secondary Processes and Reduced Errors

The manufacturing sector knows costs involved with secondary processes like welding, adhesive bonding, or fastening. Two-shot molding eliminates the need for many post-molding processes by creating multi-material or multi-colored components in a single cycle. This not only speeds up the production cycle but also reduces the chances of human error, ensuring a higher level of consistency and quality in your products.

Material and Cost Savings

By eliminating secondary processes and manual assembly, you'll save material and reduce labor costs. For example, two-shot molding can be used to produce complex parts that require multiple material properties or varying colors, in a single step. Plus, a more streamlined process means less waste, aligning well with the sustainability goals many manufacturers aim to achieve.

Enhanced Product Integrity and Durability

Creating a product using multiple materials usually involves separate molds and manual assembly. This can introduce weak points and a more costly product. Two-shot molding value streams the process by reducing part handling and optimizing machine capacity. By creating a strong bond between the different materials during the molding process itself, thereby enhancing the structural integrity and durability of the product. For instance, two-shot molding can be used to create a product with a rigid plastic under mold and an over mold of soft touch material, creating a strong fusion between the different materials in one single cycle.

Regulatory Compliance Made Easier

Many industries, particularly medical and automotive, have stringent quality standards. The precision that two-shot molding offers by reducing part handling and eliminating additional processes can make meeting these rigorous requirements more achievable. Producing a more reliable and consistent product helps adhere to industry-specific regulations, giving you one less thing to worry about.

The Seamless Transition to Two-Shot Molding

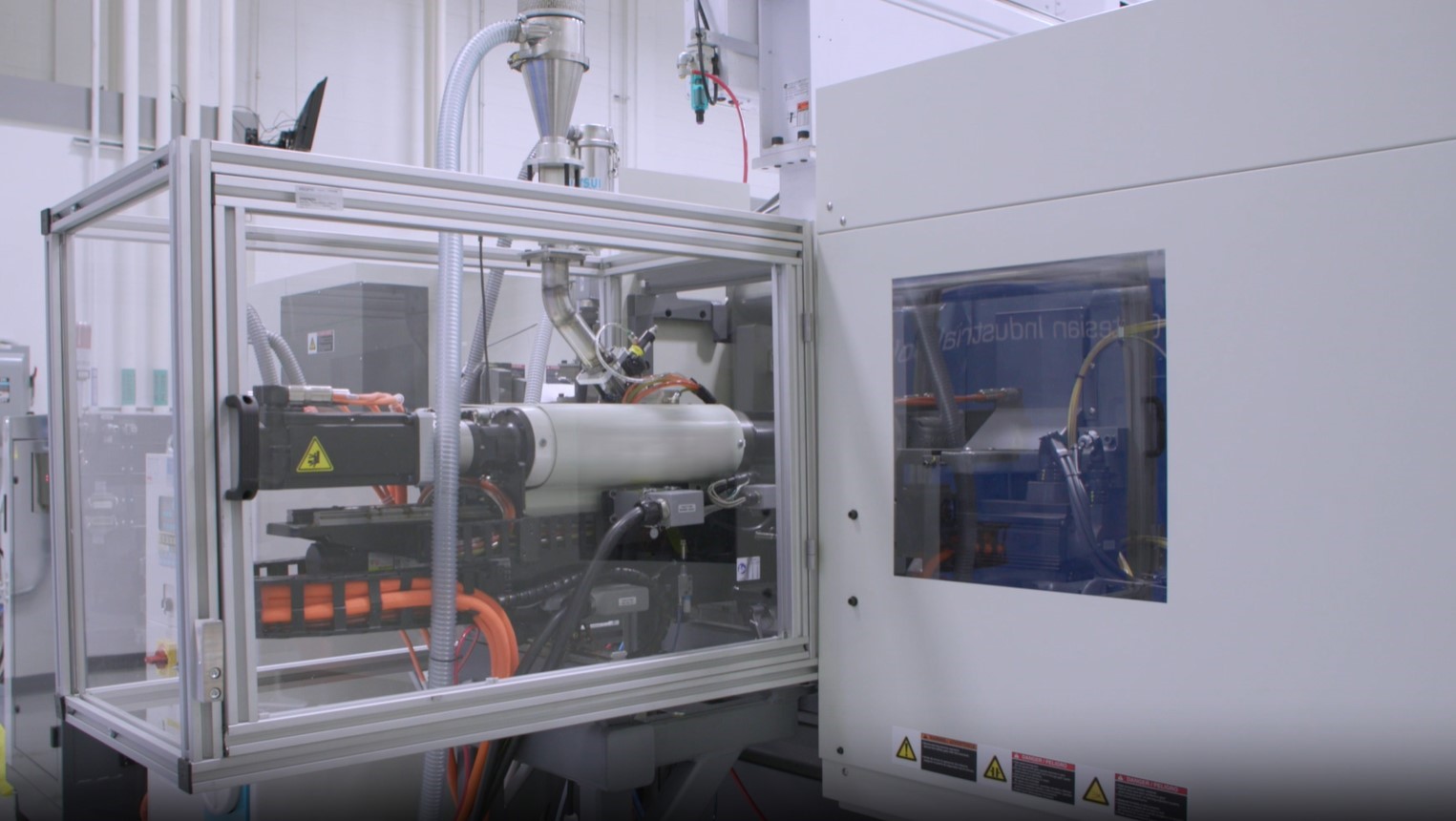

With consumer demands ever-changing, manufacturing flexibility is invaluable. Multi-Shot Systems by Shibaura Machine can be customized to your specifications, even designed to be moved from one machine to another giving you the ability to adapt to market changes swiftly. A secondary injection unit can be easily retrofitted to your existing Shibaura injection molding machine to handle multi-shot molding. This means you can tap into these benefits without needing to purchase an additional specialized two-shot molding machine.

Check out this video to learn more about our Multi-Shot injection molding systems: CLICK HERE

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Improve Your Injection Molding Process with Barrel Temperature Shift Mode

ELK GROVE VILLAGE, IL, August 23, 2023 - To ensure optimal product quality, consistency, and operational efficiency, precise temperature control plays a critical role in the injection molding process. One essential feature that can significantly impact inj...

Read moreMastering Material Changeovers in Injection Molding

ELK GROVE VILLAGE, IL, August 8, 2023 - Optimizing efficiency and minimizing costs are crucial to success in the fast-paced world of injection molding. However, one aspect that often poses difficulties for molders is the purging process. The traditional me...

Read morePartnering for Success: Shibaura Machine's Technical Sales Support Services

ELK GROVE VILLAGE, IL, July 20, 2023 - As the manufacturing landscape continues to evolve, having a reliable technical sales support team becomes increasingly important. With inefficiencies in injection molding processes translating into financial losses, ...

Read moreInvest in Your Success: Shibaura Machine's Training Programs for Injection Molding Professionals

ELK GROVE VILLAGE, IL, July 5, 2023 - When it comes to injection molding, having a well-trained team is crucial for maximizing machine performance and achieving optimal results. Training ensures that all personnel understand not only the machine's capabili...

Read moreAchieving Injection Molding Excellence with Integrated Auxiliary Equipment

ELK GROVE VILLAGE, IL, June 21, 2023 - Staying ahead of the competition in manufacturing requires adopting innovative solutions that enhance productivity and efficiency. Auxiliary equipment offers a way to enable precise and automated handling of materials...

Read moreDriving Sustainable Development: The Rise of All-Electric Injection Molding Machines

ELK GROVE VILLAGE, IL, June 7, 2023 - As sustainability becomes an increasingly important focus worldwide, industries are seeking innovative solutions to align their operations with the United Nations' Sustainable Development Goals (SDGs). In the world of ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools