Bring Real-Time Quality Monitoring to the Injection Molding Floor with Shibaura Machine

ELK GROVE VILLAGE, IL, November 2, 2022 - How efficiently and effectively are you able to control your quality processes? When quality management is running smoothly it not only maintains quality but is focused on maximizing productivity creating the best result for your investment.

However, you cannot improve the injection molding process without knowing where it continuously stands and in turn having the ability to adjust. Being able to provide real-time alerts to process inefficiencies, monitoring mold performance, and proactive quality assurance is just not feasible to accurately and efficiently perform manually. In order to create a competitive advantage, it is key to have an intuitive, real-time quality monitoring and measurement tool that automatically creates reports and alerts.

Use Quality Monitoring to Track and Control Your Process

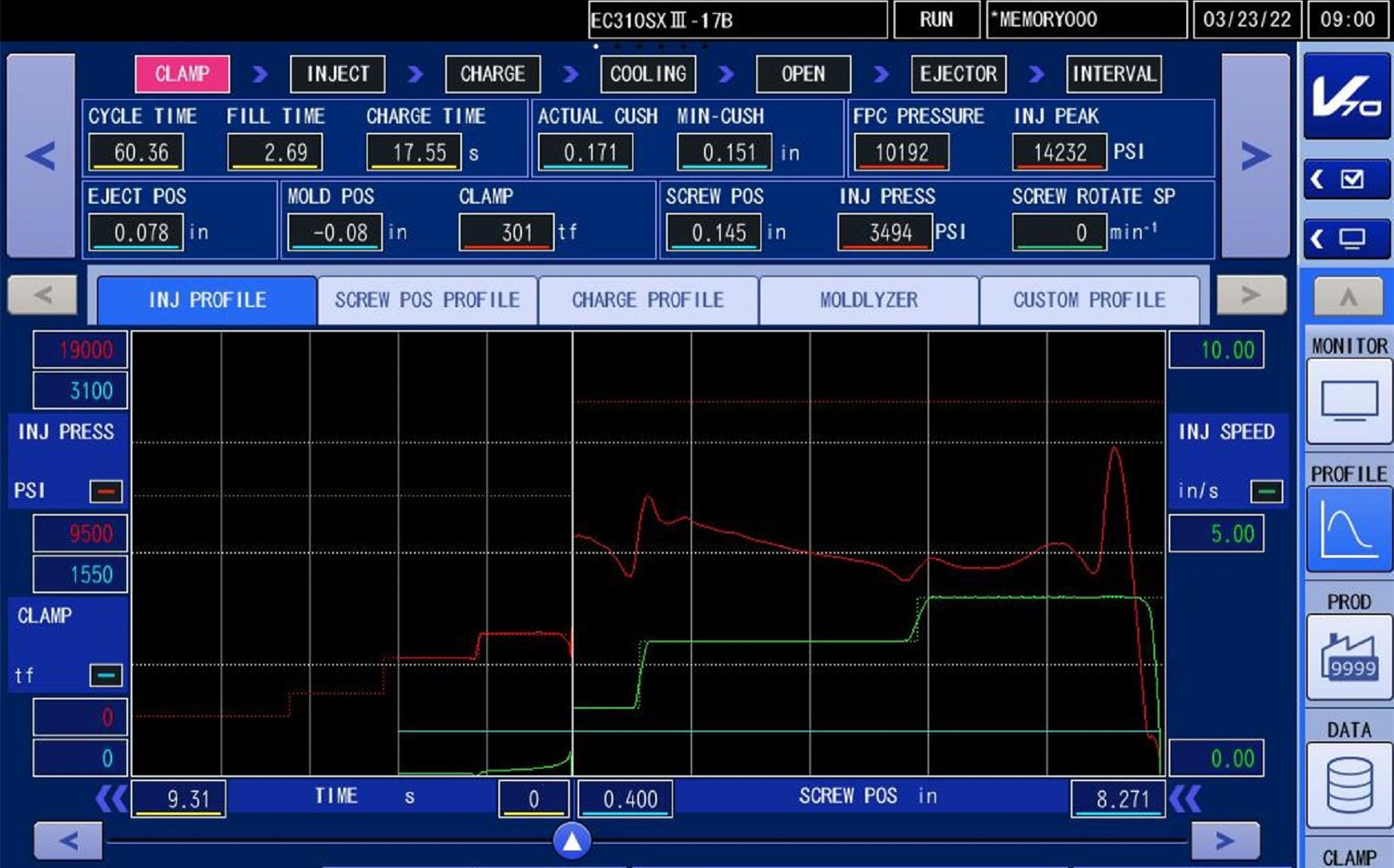

The Quality Monitoring functions on Shibaura Machine’s V70 controller allows production departments to comply with specific quality standards through monitoring the molding process in real time. This means being able to capture and track quality monitoring data for 50+ items including charge time, cushion position, and FPC (transfer) pressure. If the shot does not match the preset tolerance the machine will stop so adjustments can be made.

Working Towards Improving Overall Equipment Efficiency

These types of quality management tools help to streamline the process and not only boosts overall factory effectiveness but is held as a key metric to improving overall equipment efficiency. For example, when the process is running well the user can take a reference sample of each of the process parameters, putting a +/- tolerance around the reference points. In addition, they can set up alarms, show trends, and calculate quality statistics for the production run.

Contact the Injection Molding Team today to learn more about how your shop can gain a competitive advantage by utilizing the Quality Monitoring functions on the V70 controller.

Tel: (888)593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Now Enrolling for In-Person Injection Molding Training Courses

ELK GROVE VILLAGE, IL, August 3, 2022 - Shibaura Machine is pleased to announce our popular in-person injection molding training courses are resuming for the remainder of 2022. Customers can join us at our tech centers in Elk Grove Village, IL, Charlotte, ...

Read moreRobot Integration Simplified With Shibaura Machine

ELK GROVE VILLAGE, IL, June 29, 2022 - Automating tasks with robots has become an increasingly popular option for injection molding manufacturers. From placing inserts into molds to moving parts through post-mold processes, robots provide process stability...

Read moremachiNetCloud Industrial IoT Now Included on New Injection Molding Machines

ELK GROVE VILLAGE, IL, June 22, 2022 - As the landscape in manufacturing continues to rapidly change due to digitalization, the Industrial Internet of Things (IIoT) brings a great opportunity to gain a competitive advantage in every form of production, inc...

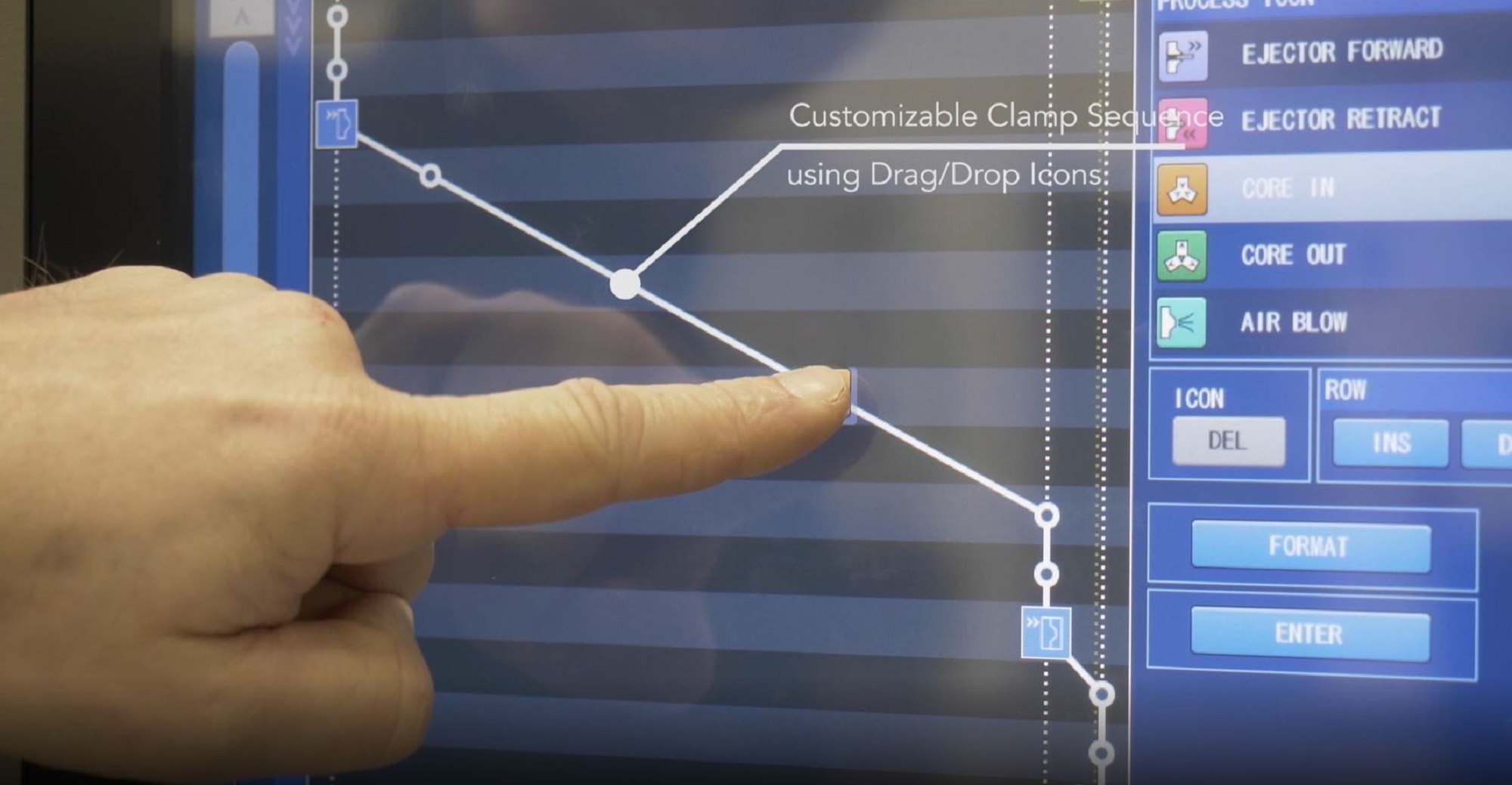

Read moreCustomize Your Clamping Sequence at a Touch

ELK GROVE VILLAGE, IL, June 17, 2022 - One of the steps to get the best results from injection molding requires the operator to properly set up the clamping sequence. Without an intuitive and visual experience, setting this up can be a time-consuming and d...

Read moreRegistration is Open For Our Injection Molding Smart Factory Open House

ELK GROVE VILLAGE, IL, April 28, 2022 - Merging existing technologies with new innovations can be challenging for manufacturers. To help injection molding factories envision the future of manufacturing, Shibaura Machine has partnered with key industry part...

Read more4 Ways to Ensure Precision Filling Transfer Using Final Pack Control

ELK GROVE VILLAGE, IL, March 24, 2022 - The more you can control your production conditions in injection molding the more repeatable your results. When it comes to transfer from the filling stage to packing it might be considered the most crucial element o...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools