Using Programmable Outputs to Improve Injection Molding Productivity

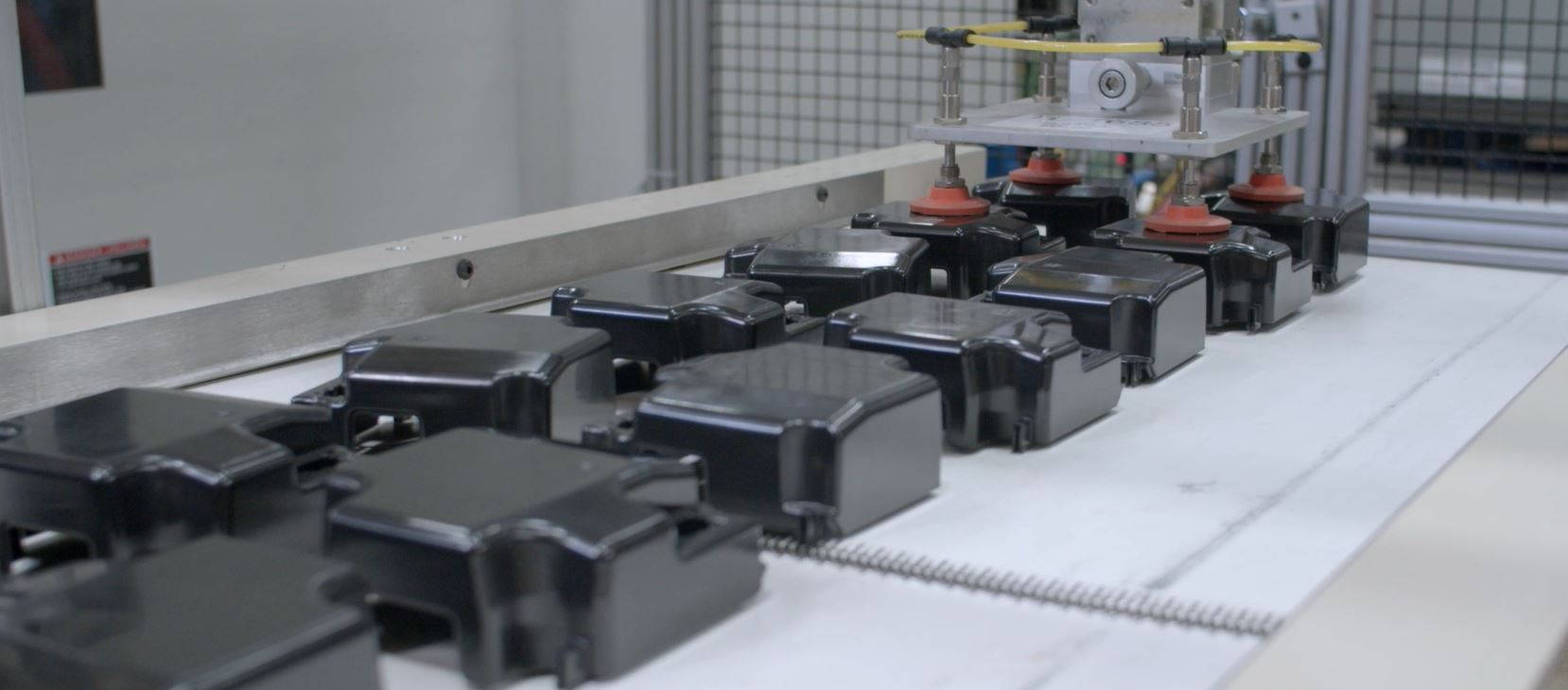

ELK GROVE VILLAGE, IL, May 12, 2021 - The demand for quality parts quickly continues to grow. Shop floors are working to meet customer requirements and being able to boost efficiency in production is key. Having the flexibility of connecting auxiliary equipment easily into your injection molding machine to streamline communication can prove to be a major contributor to improving both cost effectiveness and productivity.

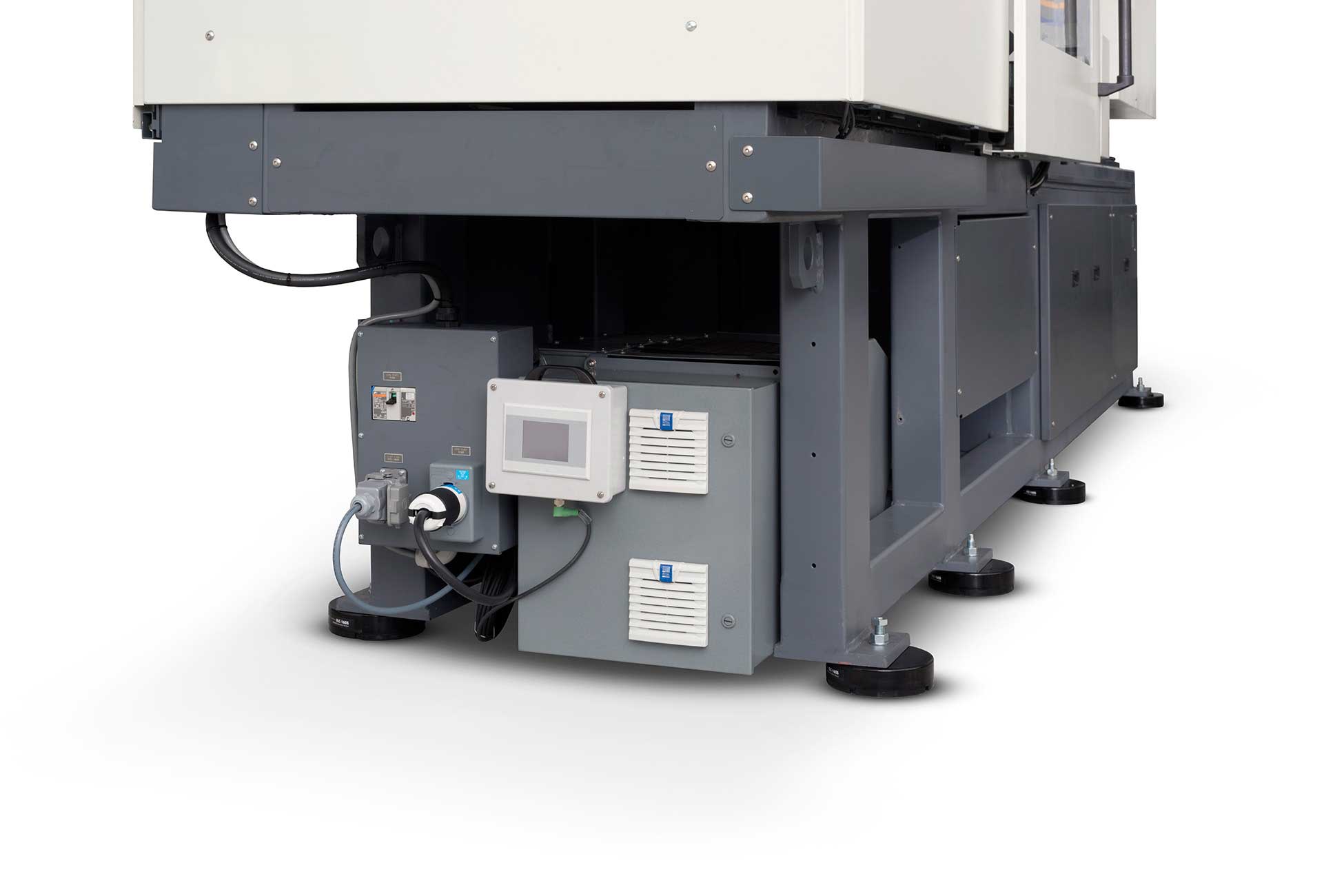

Shibaura Machine’s ECSXIII all-electric injection molding machines come standard with 6 freely programmable outputs (with the option to add additional as needed) in order to help facilitate communication between the machine and auxiliary equipment.

Operating Made Smarter

When utilized, programmable outputs not only afford your technicians freedom to perform other operations, but allow for a more efficient production with less stop and go in the process. Utilizing programmable outputs is one of the most cost effective options to automate auxiliary controls.

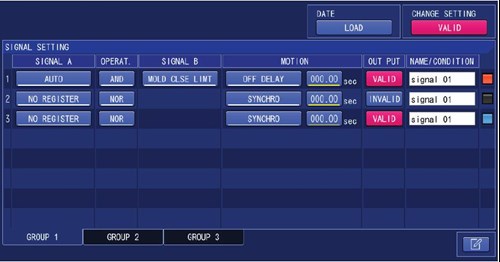

The programmable outputs on the ECSXIII all-electric machines allow users to freely customize a signal output from the molding machine that can be sent to an external piece of equipment via a dry contact in the machine control cabinet. This feature comes into play whenever an external piece of production equipment needs a signal from the injection molding machine in order to perform its intended operation. The efficiency of the injection molding process is able to be significantly improved by automating various programs of the machine.

Examples include:

- Sending the screw charging signal to a color feeder so color can be dosed into the material stream

- Sending a reject shot signal to a reversing conveyor or part diverter chute so suspect parts are separated from good parts

- Sending a shot count complete signal to a box filling system

- Sending a temperature standby signal to a hot runner controller to prevent resin degradation

A Solution to Save Time

Are you wondering how you can improve your efficiency in production while still being able to consistently produce quality parts? The ECSXIII all-electric injection molding machine's programmable outputs offer a solution to save time, and ultimately money, by removing the need for technicians to step in and program various operations.

Contact our injection molding team to learn more about how your shop floor can utilize the programmable outputs on our ECSXIII all-electric injection molding machines.

Contact us today to learn how the ECSXIII series machines can make your shop more productive!

Related Articles View All Articles

Shibaura Machine Makes Core Pull on All Electric Injection Molding Machines Simple

ELK GROVE VILLAGE, IL, May 5, 2021 - Many molds rely on core pull in order to produce their final product successfully. Whether it’s a hollowed out container, unscrewing features in the tool, or ejecting parts- the core pull feature provides shops a way to...

Read moreIntroducing Injection Molding “Tech Talk Thursday” Webinar Series

ELK GROVE VILLAGE, IL, April 22, 2021 – Profitability and competitive advantage. These are two things factories strive for when it comes to their injection molding operation. Owners and operators alike are continually working to be as efficient as possible...

Read moreServices to Keep Your Injection Molding Machines Running Efficiently

ELK GROVE VILLAGE, IL, April 14, 2021 – High quality parts come from high quality machinery. In order to keep your injection molding machines running efficiently with minimal downtime it's important to have the backing of a strong service team. Most moldin...

Read moreMinimize Injection Molding Downtime with a Good Parts Partner

ELK GROVE VILLAGE, IL, April 8, 2021 – Even with impeccable maintenance, your injection molding machine will find itself needing spare parts at some point. When that time comes, having a machine partner that can get you the correct part easily and efficien...

Read moreHow Injection Molding Training Maximizes Your Machine ROI

ELK GROVE VILLAGE, IL, April 1, 2021 – Having a comprehensive understanding of your injection molding machine will not only improve your production processes, but overall profitability. Setting this type of foundation is not only a smart investment in your...

Read moreThree-Stage Mold Protection Saves Time and Money

ELK GROVE VILLAGE, IL, March 24, 2021 – Mold protection often goes overlooked, but mold damage and downtime can be prevented by utilizing this feature properly. Each mold has its own requirements, so having a machine that makes input and monitoring easy is...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools