Unlocking Efficiency and Security: Best Practices for Remote Troubleshooting in IIoT-enabled Manufacturing

ELK GROVE VILLAGE, IL, May 26, 2023 -

In today's rapidly evolving manufacturing landscape, remote troubleshooting and security have become critical aspects of operational efficiency and resilience. Manufacturers face the challenge of resolving issues promptly while ensuring the highest level of security for their industrial systems.

Remote troubleshooting for industrial equipment maintenance has come in to provide a variety of benefits for the manufacturer.

- Minimized downtime: Prompt issue identification and resolution reduce production interruptions, ensuring minimal downtime and swift recovery.

- Cost savings: Elimination of on-site visits reduces travel expenses and logistics-related costs, optimizing resource allocation.

- Rapid response: Remote troubleshooting enables faster assistance, preventing extended production delays and maintaining high productivity.

- Access to specialized expertise: Remote access connects manufacturers with skilled technicians and engineers regardless of location, enhancing problem-solving capabilities.

- Reduced repair time: Real-time troubleshooting speeds up the repair process, minimizing equipment downtime and improving operational efficiency.

- Global support: Centralized technical assistance provides consistent and efficient problem-solving across multiple locations, overcoming geographical limitations.

However, not all remote access methods are equal in terms of security and ease of deployment. Companies need to carefully assess the values and review different options to establish a secure and effective remote access strategy.

Developing a 3-Step Remote Access Plan

Developing a comprehensive remote access plan is crucial for organizations seeking to streamline operations, enhance safety, minimize production disruptions, and maintain quality standards.

Below is a 3-step guide to help you establish a robust remote access plan while considering key factors such as personal safety, verification, risk management, equipment safety, technical problems, quality assurance, and the need for local assistance. By integrating these considerations into your plan, you can optimize remote access procedures and foster a secure, efficient, and high-quality working environment.

Step 1: Identify and Classify Remote-Accessible Activities

Start with a review of current on-site operations and determine which activities can be performed remotely. Closely examine each function and assess the feasibility of remote execution. Consider factors such as personal safety, risk management, and equipment safety to determine if a particular task can be safely conducted from a remote location. Classify these activities based on their compatibility with remote access, ensuring a clear understanding of what can be done remotely and what requires on-site presence.

Step 2: Define Access Rules Based on Machine States

To ensure a smooth and controlled remote access process, establish access rules that are tied to machine states. For example, differentiate between access permissions for machines in production and those that are not currently running. Align your remote access rules with the existing rules for on-site equipment access to maintain consistency. Additionally, incorporate safety rules to regulate access to hazardous areas and equipment, promoting a secure working environment for both remote and on-site personnel.

Step 3: Develop a Manual Process and Mutual Agreement

To facilitate effective remote access, it is essential to establish a manual process that outlines the steps, protocols, and responsibilities involved. This process should be developed in collaboration with all relevant stakeholders, including third-party experts, to ensure a mutual understanding of expectations and limitations. Emphasize the importance of obtaining approval before accessing any equipment, whether on-site or remotely. By adhering to a clear manual process, you can ensure accountability, compliance, and a seamless remote access experience.

Challenges and Limitations of Traditional Remote Access

Traditional remote access methods often rely on username and password authentication, which may not provide sufficient security for manufacturers. Multiple external operators requiring remote access can lead to weak authentication practices, leaving the shop floor vulnerable to attacks and exploits. Moreover, granting access to the Virtual Private Network (VPN) often results in unrestricted visibility and access to all shop floor network assets, posing a high degree of vulnerability.

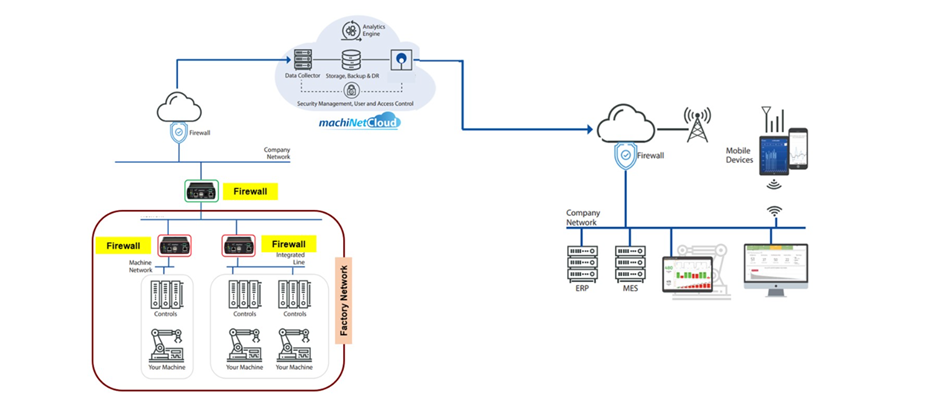

Direct VPN

In this method, the customer's firewall requires the customer to grant permission to the OEM for access to the network that contains the production operations control devices. This establishes a secure VPN connection.

Converged Network

This approach involves the customer's firewall and an additional secure switch(s). The customer grants permission to the OEM for access to a segmented section of the network where the production operations control devices are located. This creates a secure connection for remote access.

Both the Direct VPN and Converged Network methods require dedicated IT staff with a high level of IT skills. These staff members are responsible for maintaining security updates, firmware updates, and other related tasks.

A Structured Approach to Remote Access Design

To address the security concerns and limitations of traditional remote access methods, a structured approach to remote access design is crucial. An external managed secure network allows the OEM to provide a third-party cloud service and device that establishes a dynamic secure VPN tunnel through the customer's firewall. This method includes software features that allow customers to grant individual access to a segmented section of the production operations control devices.

This option can be more cost-effective compared to the other approaches, as it doesn't require changes to the existing network infrastructure. It also provides the same or even higher level of security as the Direct VPN or Converged Network methods, designed to ensure both IT and OT (Operational Technology) requirements are met.

Ensuring IT Approval

IT approval is vital for the successful implementation of a remote access solution. IT teams are responsible for maintaining data infrastructure, security, and integrity. To gain IT acceptance, a remote access solution must provide fine-grained access control, manageable configuration options, and verifiability through independent auditing. Robust encryption methodologies and user authentication mechanisms are essential for securing data transmission across non-trusted networks.

Easily OT Managed

OT teams play a crucial role in managing and securing industrial operations. They require controlled access and privileges, enabling them to optimize asset utilization and reduce machine downtime while maintaining data security. A centralized control platform that offers granular access controls and provides auditability of user actions ensures accountability and secure operation.

Future-Readiness

A remote access solution must go beyond crisis management and offer continuous data collection, trend analysis, and support for future needs. Organizations should prepare for evolving cybersecurity threats by implementing a solution that supports remote access as a means of operation and provides comprehensive data analysis capabilities.

The design of Shibaura Machine’s machiNetCloud accommodates the needs of both IT and OT, fostering a seamless connection between the two. It ensures IT approval through its secure two-tier access solution, with the green Amphion handling encryption and data consolidation, and multiple red Amphions isolating individual machines. The unified machiNetCloud Customer Portal allows both teams to manage users, security credentials, and access rights.

Start Driving Productivity and Protection

Remote troubleshooting best practices and security are paramount in the age of IIoT. By adopting a structured approach to remote access design and leveraging solutions like Shibaura Machine's machiNetCloud, organizations can ensure secure and efficient remote access while meeting the requirements of both IT and OT teams.

Embracing the future-readiness of industrial networking and evaluating remote access solutions based on key questions will empower organizations to unlock the full potential of their operations, deliver value to customers, and stay ahead of new challenges.

Contact the Digital Services Division to learn more.

Related Articles View All

Bring Quality Management to New Levels with Digital Six Sigma

ELK GROVE VILLAGE, IL, August 17, 2022 - A streamlined quality management process not only boosts overall factory effectiveness but as a key metric to improving overall equipment efficiency (OEE), is extremely important to maintaining a competitive advanta...

Read moreHow to Bring Digital Six Sigma Process to Your Factory to Reduce Downtime

ELK GROVE VILLAGE, IL, July 28, 2022 - What strategies has your factory taken on to reduce the amount of unplanned downtime due to machine issues? From preventative maintenance to redundancy, and even increasing planned downtime to reduce unplanned downtim...

Read moreHow IIoT is Improving Six Sigma

ELK GROVE VILLAGE, IL, July 15, 2022 - Over the years, Six Sigma practices have created billions of savings for the manufacturing world. Working towards the fundamental goal of creating the most efficient system possible and eliminating waste, Six Sigma pr...

Read moreA Better Way to Track Downtime in Manufacturing is Finally Here

ELK GROVE VILLAGE, IL, May 18, 2022 - Avoiding unplanned downtime and minimizing planned downtime is the golden ticket to manufacturing success. Through the years, manufacturers have implemented various strategies to maximize machine utilization and suppor...

Read moreRemote Troubleshooting is Less Complex Than You Think

ELK GROVE VILLAGE, IL, April 29, 2022 - Industrial machinery is the lifeblood of manufacturers. As many begin to recover and restart in the next normal, many see it as an opportunity to reimagine a future with increased digitization to create more resilien...

Read moreCreate a True Path Forward to Improving Your OEE with machiNetCloud

ELK GROVE VILLAGE, IL, April 14, 2022 - When it comes to operation optimization many manufacturers are still left wondering the best ways to move forward. Utilizing spreadsheet and clipboard methods are still commonplace, but unfortunately lacks the detail...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools