VDI Manufacturing: Overcoming Challenges with Shibaura Machine's machiNetCloud

VDI Manufacturing is a veteran-owned company whose primary mission is Production Injection Molding, Assembly, and Tooling. In addition, offers a full complement of prototyping services including: design assistance, 3D printing, quick-turn aluminum tooling, and prototype molding. VDI also offers an on-site ISO/IEC 17025:2017 Accredited Metrology Lab to certify quality and dimensions on every project. VDI’s collective experience dates back to the 1980s and is backed by state-of-the-art, Shibaura Machine all-electric molding machines, and automated processes.

machiNetCloud - A Game-Changer for Our Business

The Challenge

Before implementing Shibaura Machine’s machiNetCloud, VDI Manufacturing struggled with several critical issues.

- Capacity Estimation: Without real-time data, VDI often miscalculated their actual capacity, leading to inefficient operations.

- Productivity Tracking: They lacked a reliable way to quickly output Key Performance Indicators (KPIs).

- Tool Lifecycle and Downtime Management: Tracking the life cycles of tools, downtime, and scrap was a major hurdle, especially for a lean team.

"Before we had machiNetCloud, we looked busy, but to what degree? We'd sit there and try to estimate what our capacity was or how much of our capacity we were using, and we were off."

Jeff Becker

Owner

The Solution

After thorough research, VDI Manufacturing chose Shibaura Machine for their proven reliability and innovative solutions. The launch of machiNetCloud was a game-changer for VDI.

Implementation:

Shibaura Machine worked closely with VDI to integrate machiNetCloud with their existing machinery. This included customization to fit their production lines and comprehensive training for their operators. The smooth integration ensured minimal disruption to VDI’s ongoing operations.

Key Metrics:

- Capacity Utilization: Becker explains, “machiNetCloud made it very clear. I didn't need more machinery. I needed to sell 60% to 70% of the capacity that I had available on the floor right now."

- Efficiency Improvement: VDI experienced a tenfold improvement in efficiency due to real-time data accessibility.

- Decision Making: The ability to quickly evaluate capacity and productivity enabled better business decisions and optimized resource utilization.

Results

The implementation of machiNetCloud had an immediate and profound impact on VDI Manufacturing’s operations.

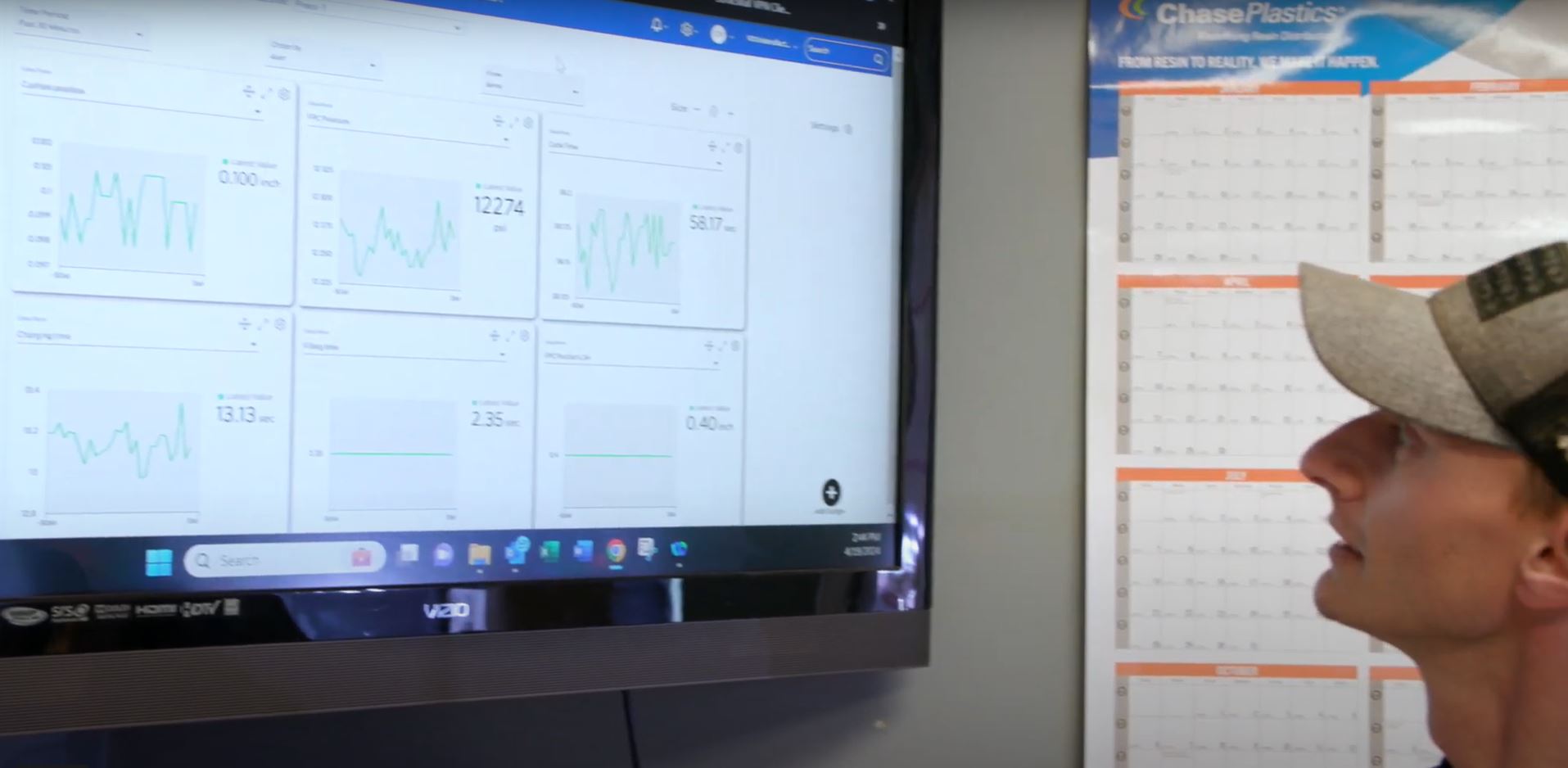

- Real-Time Data: Access to real-time data allowed VDI to make informed decisions quickly. "Our efficiency has improved with machiNetCloud tenfold, just being able to grab the data that I need to make decisions,” explains Chad VanHaun, General Manager of VDI Manufacturing

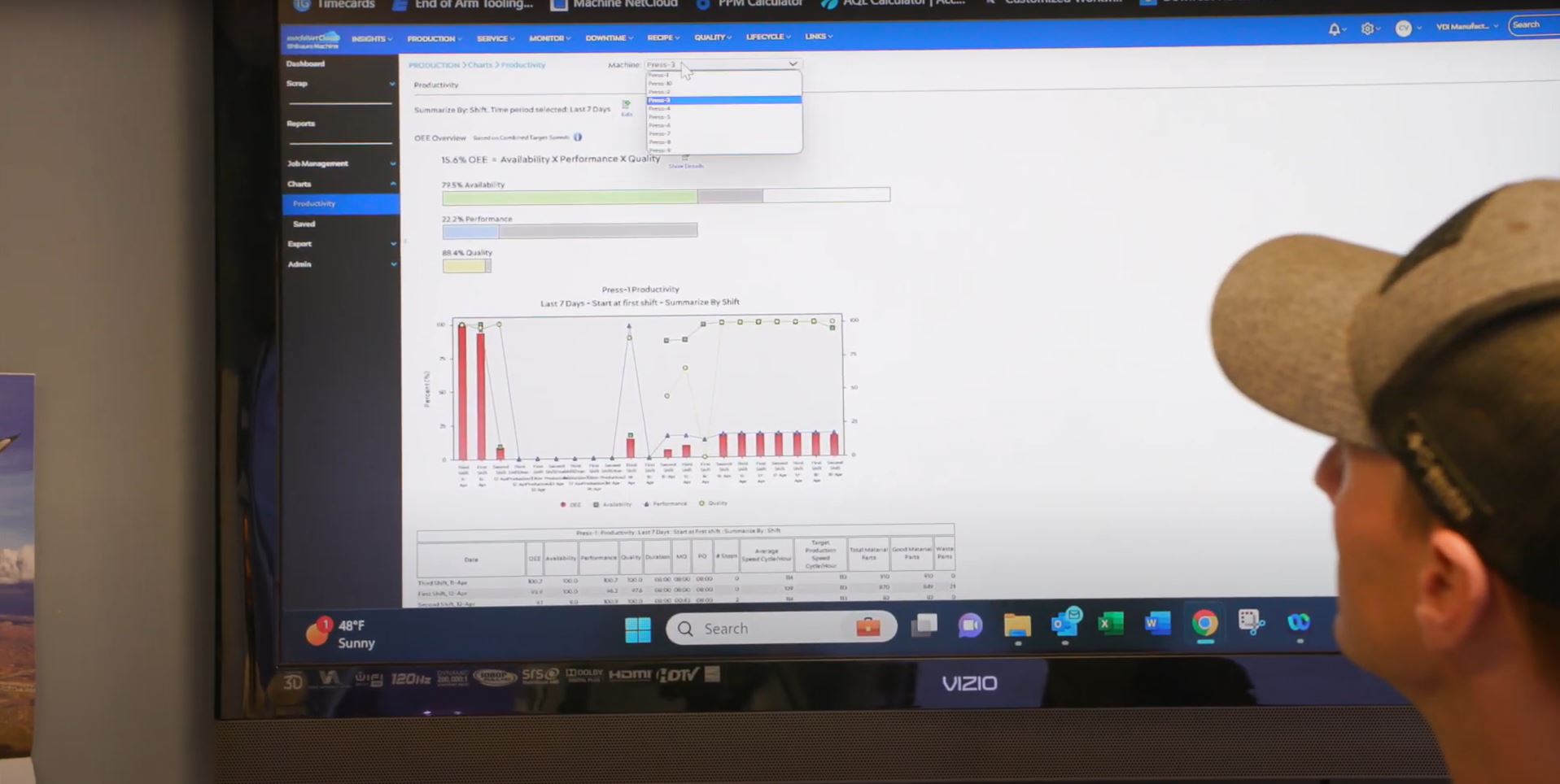

- Productivity: The ability to evaluate OEE in weekly management meetings helped identify and address productivity gaps swiftly.

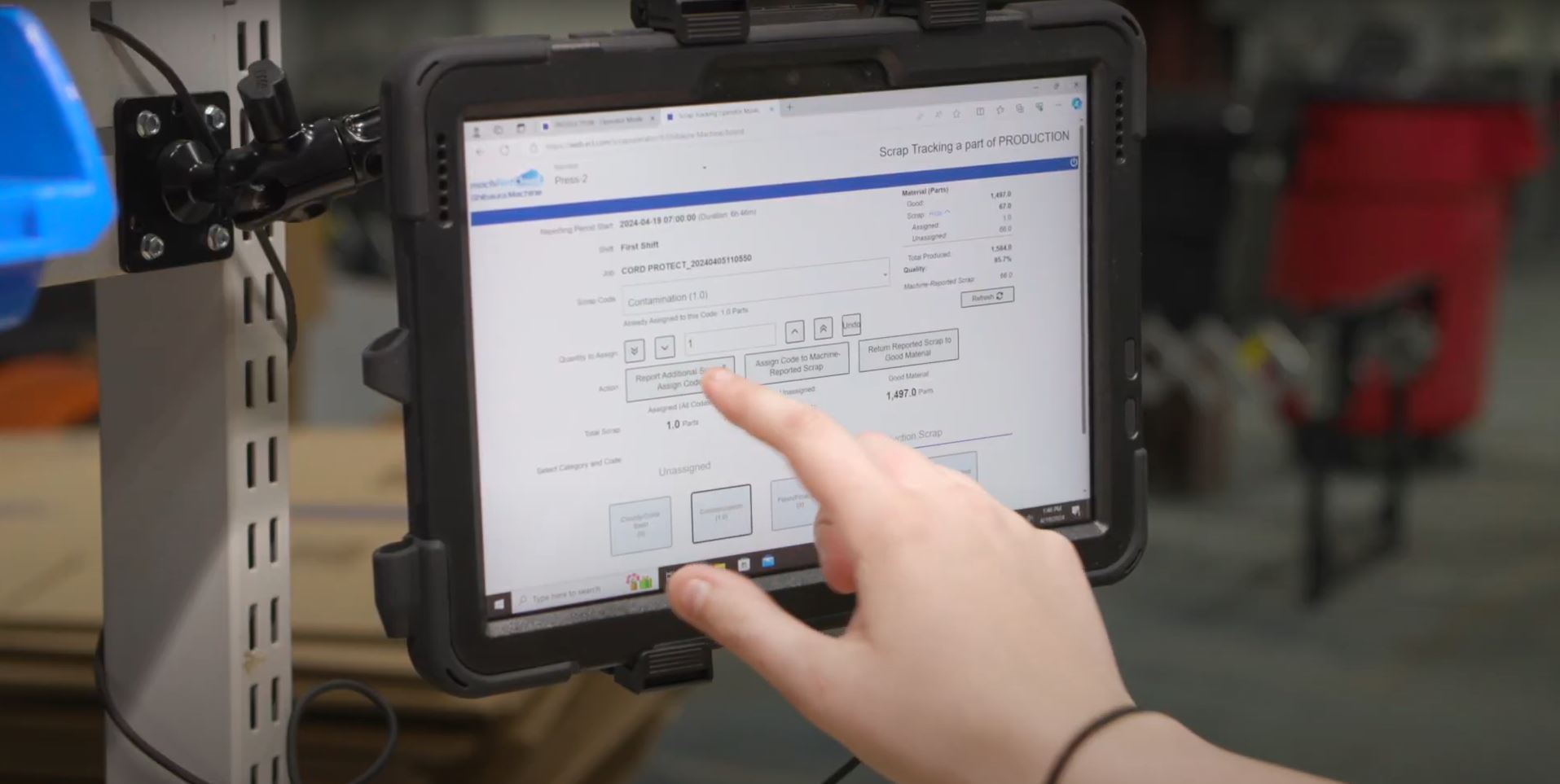

- Scrap Management: Real-time scrap alerts significantly reduced response times to issues, enhancing overall quality control.

“Manufacturing has a lot of challenges in and of itself, and machiNetCloud enabled us to overcome a lot of those.”

Chad VanHaun

General Manager

VDI Manufacturing now enjoys sustained improvements in productivity and operational efficiency. The real-time tracking and data analysis capabilities of machiNetCloud have positioned VDI for future growth and success.

"Being able to evaluate our OEE in a weekly management meeting, we're able to quickly analyze and understand where any gaps might be in our productivity or our manufacturing process," Chad noted. "It's extremely powerful and it makes it a no-brainer for me to choose Shibaura."

Future Plans for Innovation and Growth:

VDI Manufacturing continues to collaborate with Shibaura Machine to optimize their production processes further. Plans include leveraging more machiNetCloud capabilities and upgrading additional production lines.

With the support of Shibaura Machine, VDI Manufacturing is excited about exploring advancements in automation and AI to enhance their production capabilities further. This ongoing innovation is expected to maintain their competitive edge in the custom injection molding industry.