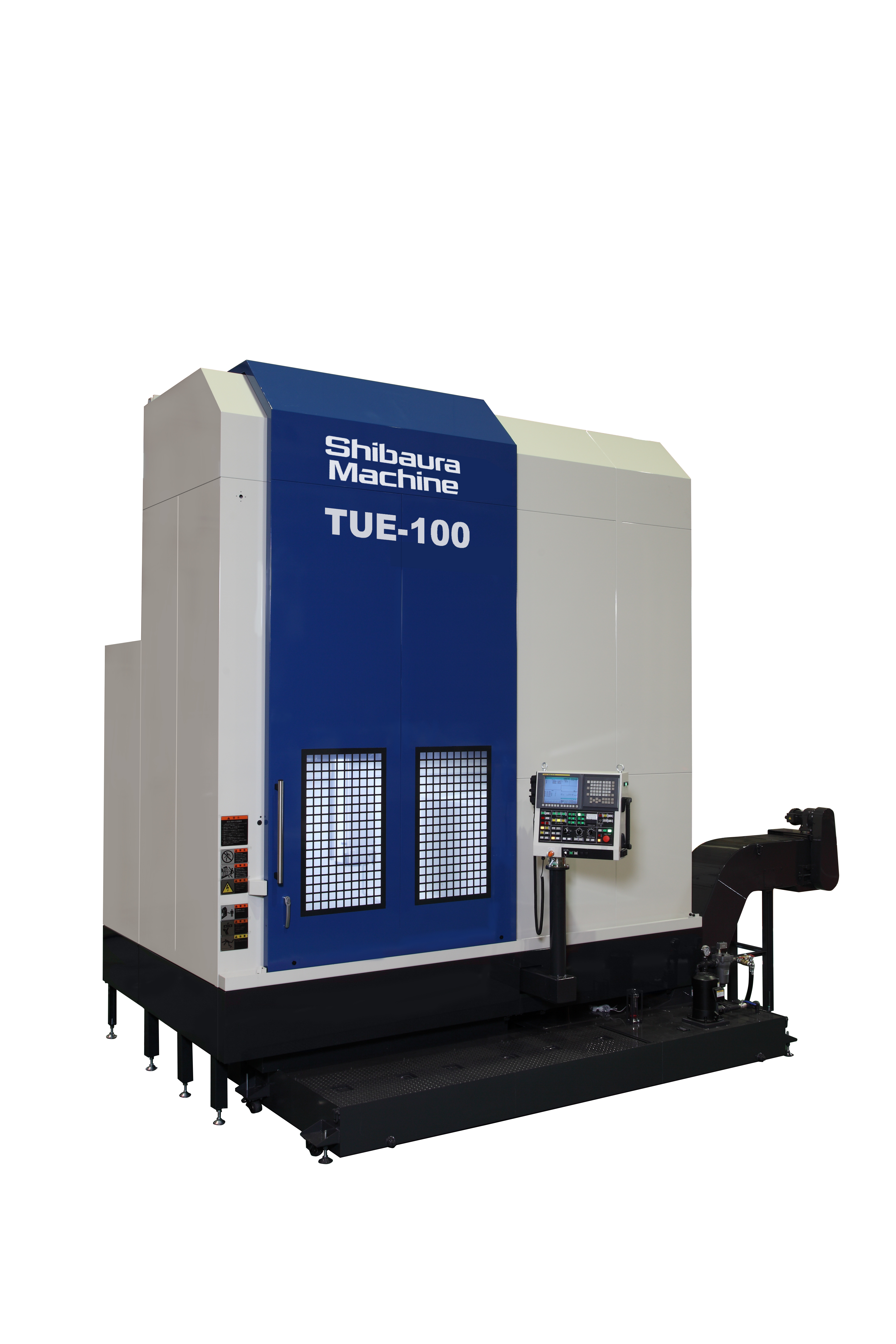

TUE-100(S)

Vertical Boring & Turning Mill TUE Machine

Workpieces made of various kinds of material can be machined using the TUE-100(S) Vertical Boring & Turning Mill. The TUE-100(S) Vertical Boring & Turning Mill can be machined on the wall-type column with its high rigidity and wide table speed.

Alesatrice e tornio verticale – Diametro max / Capacità di taglio (pollici)

Alesatrice e tornio verticale – Altezza di taglio (pollici)

Z Stroke - US Standard (in)

Alesatrice e tornio verticale – Dimensione del piano (pollici)

Alesatrice e tornio verticale – Carico massimo (lbs)

| Swing/Cut inch(mm) | 47.2 (1200) |

|---|---|

| Cut Height inch(mm) | 33.5 (850) |

| X Stroke inch(mm) | -20.0 ~ 29.5 (-510 ~ 750) |

| Z Stroke inch(mm) | 31.4 (800) |

| Table size inch(mm) | 40 (1016) |

| Max. load lbs(kg) | 4400 (2200) |

| Table RPM | 600 |

| Live Spindle RPM | 3,000 |

| ATC Tool Pod | 18 |

| Control | FANUC 0i-TF |

Dual Face Contact, Coolant Through Spindle (CTS)

Dual face contact with coolant through spindle function is standard feature

Linear Scale Feedback (X-axis)

X-axis linear scale feedback in order to achieve high accuracy

Table Lubricant Oil Cooling unit

The bed is made of cast iron, having rationally arranged ribs to completely support the table. Additionally, a thermally symmetrical design and a standard equipped lubricant oil cooling unit contribute to minimize thermal distortion to realize a high thermal-rigidity structure

Live Spindle (15 ~ 3000 RPM)

Live spindle head, AC 25/20 HP, 15 ~ 3,000 RPM

7/24 taper No. 50

Type of tool shank, 7/24 taper No. 50

Half cover style enclosure (Optional)

Half cover style enclosure also available to lower the machine height dimension

Automatic measuring RENISHAW probe (Optional)

This unit consists of a radio touch probe made by Renishaw, a standard measuring software designed by Shibaura Machine and calibration block for checking compensation value of touch probe

Automatic Tool setting RENISHAW probe (Optional)

This unit consists of a Renishaw probe to measure tool length and compensate value of tool offset

Download

0.95 mB