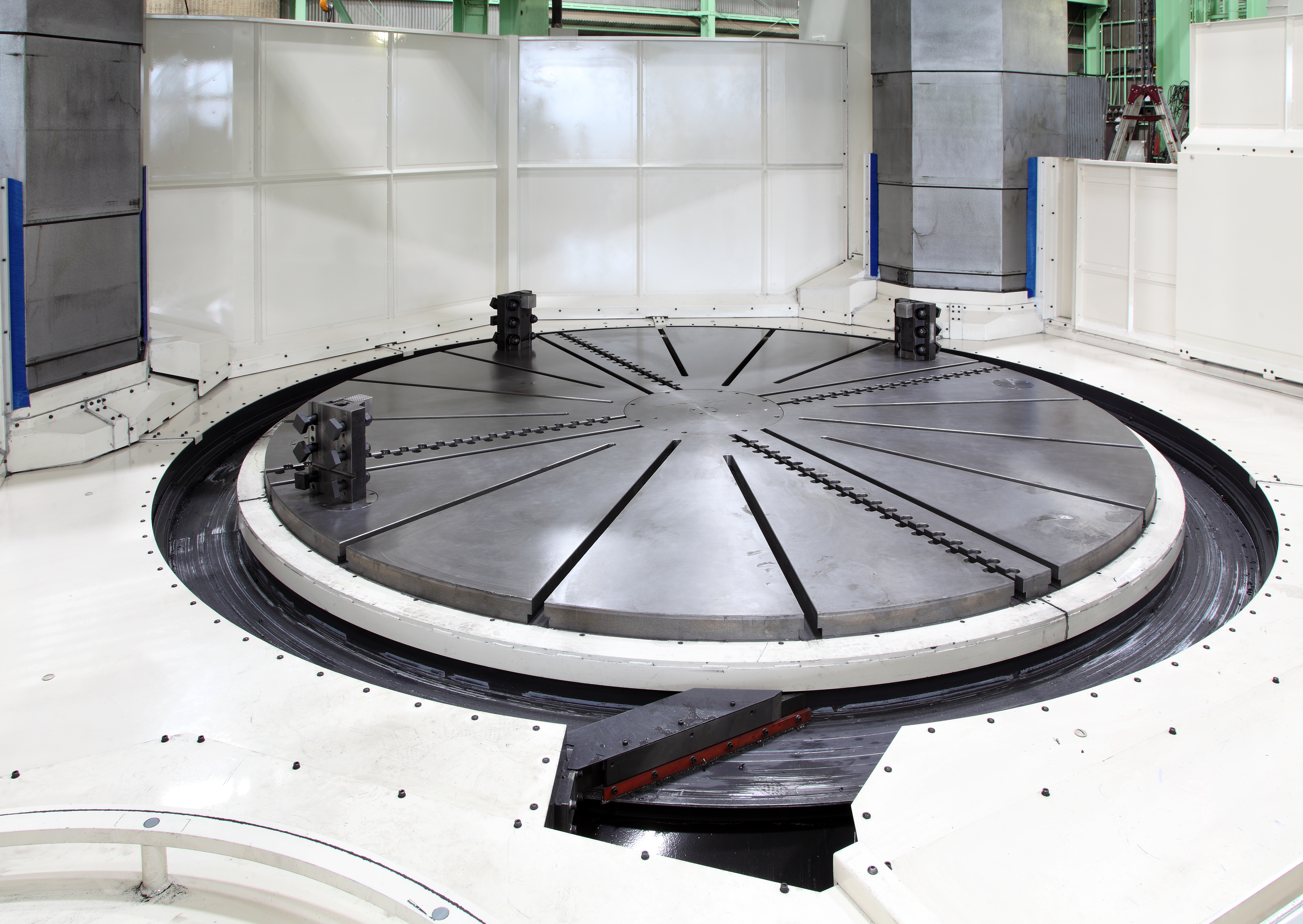

TDS-30/40(S)

Vertical Boring & Turning Mill TDS Machine

The TDS-30/40(S) Vertical Boring & Turning Mill is used to manufacture large diameter and heavy workpieces with exceptional accuracy and productivity.

Contact Shibaura today to learn more.

Swing/Cut - US standard (in)

Cut Height - US Standard (in)

Z Stroke - US Standard (in)

Table Size - US Standard (in)

Max Load - US Standard (lbs)

| Swing/Cut inch(mm) | 157.5 (4000) |

|---|---|

| Cut Height inch(mm) | 98.4 (2500) |

| X Stroke inch(mm) | -80.7 ~ 84.6 (-2050 ~ 2150) |

| Z Stroke inch(mm) | 59.0 (1500) |

| ARM/Crossrail Vertical Travel Not NC-Axis inch(mm) | 68.9 (1750) |

| Table size inch(mm) | 118.1 (3000) |

| Max. load lbs(kg) | 66000 (30000) |

| Table RPM | 150 |

| ATC Tool Pod | 24 |

| Control | FANUC 31iB |

RAM-type Spindle Head (Attachment change capable)

The thick, 14.96”-square (380mm-square), ram is hardened and ground with high accuracy on straightness, squareness and parallelism.

393 ipm (10,000 mm/min) X, Y and Z-axes Feed Rate

With a maximum feedrate of 393 ipm (10,000mm/min) for high-speed axis feed, actual idle time is minimized for greatly improved productivity.

Table Lubricant Oil Cooling unit

The bed is made of cast iron, having rationally arranged ribs to completely support the table. Additionally, a thermally symmetrical design and a standard equipped lubricant oil cooling unit contribute to minimize thermal distortion to realize a high thermal-rigidity structure

Automatic Attachment Changer (AAC) (Optional)

AAC function is Automatic Attachment Changer. AAC provides higher productivity for your operations.

Automatic Attachment Tool Changer (AATC) (Optional)

AATC function is designed for ATC for attachments. AATC provides higher productivity for your operations.

Automatic attachment indexing device (AAI - 5deg. -1deg.) (Optional)

There are two ways for program as bellow. Automatic indexing at every 5 degree or every 1 degree: M37C. When selected three-dimensional coordinate conversion in CNC: G37C.

Automatic measuring RENISHAW probe (Optional)

This unit consists of a radio touch probe made by Renishaw, a standard measuring software designed by Shibaura Machine and calibration block for checking compensation value of touch probe

Automatic Tool setting RENISHAW probe (Optional)

This unit consists of a Renishaw probe to measure tool length and compensate value of tool offset