BTH-150.R35

Horizontal Boring Machine BTH Machine

With the experience of over 8,000 machines including continual technical improvements, the BTH-150.R35 series Horizontal Boring Mill has been developed to provide horizontal boring operational ability with machining center productivity and flexibility.

Spindle Diameter - US Standard (in)

X Stroke - US Standard (in)

Y Stroke - US Standard (in)

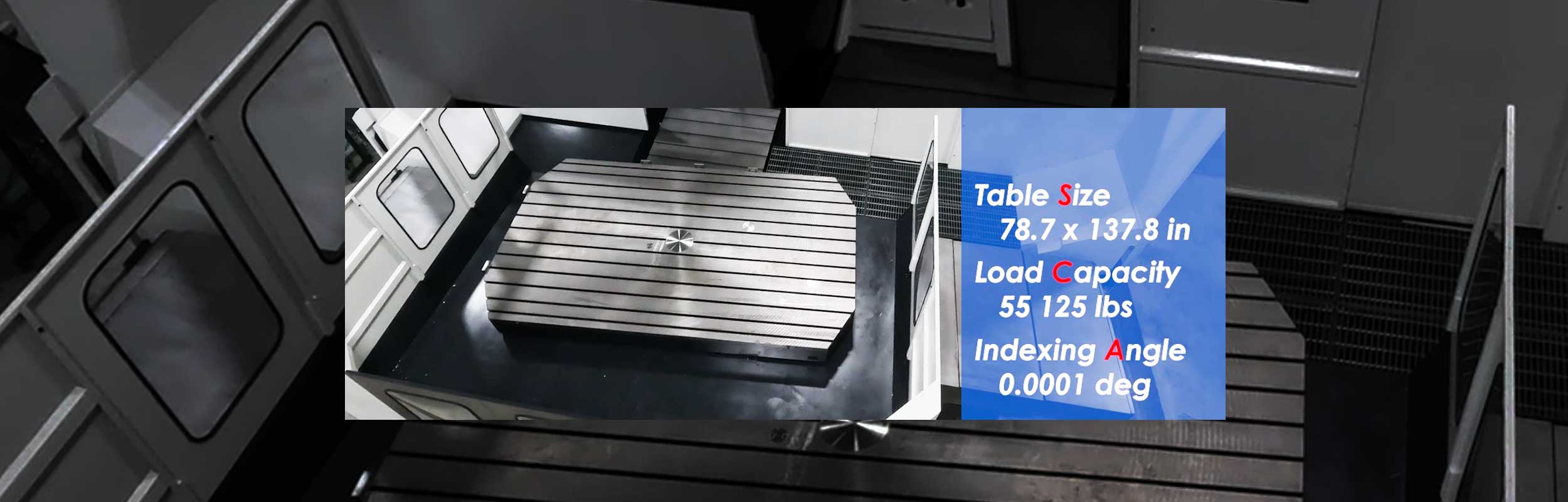

Table Size (WxL)- US Standard (in)

Max Load - US Standard (lbs)

| Spindle Dia. inch(mm) | 5.9 (150) |

|---|---|

| X Stroke inch(mm) | 157.5 (4000) |

| Y Stroke inch(mm) | 137.8 (3500) |

| Z Stroke inch(mm) | 86.6 (2200) |

| W Stroke inch(mm) | 27.5 (700) |

| Spindle (rpm) | 2500 |

| TABLE size inch(mm) width x length | 79 x 137.8 (2000 x 3500) |

| Max. load lbs (kg) | 55,000 (25,000) |

| ATC Tool Pod | 60 |

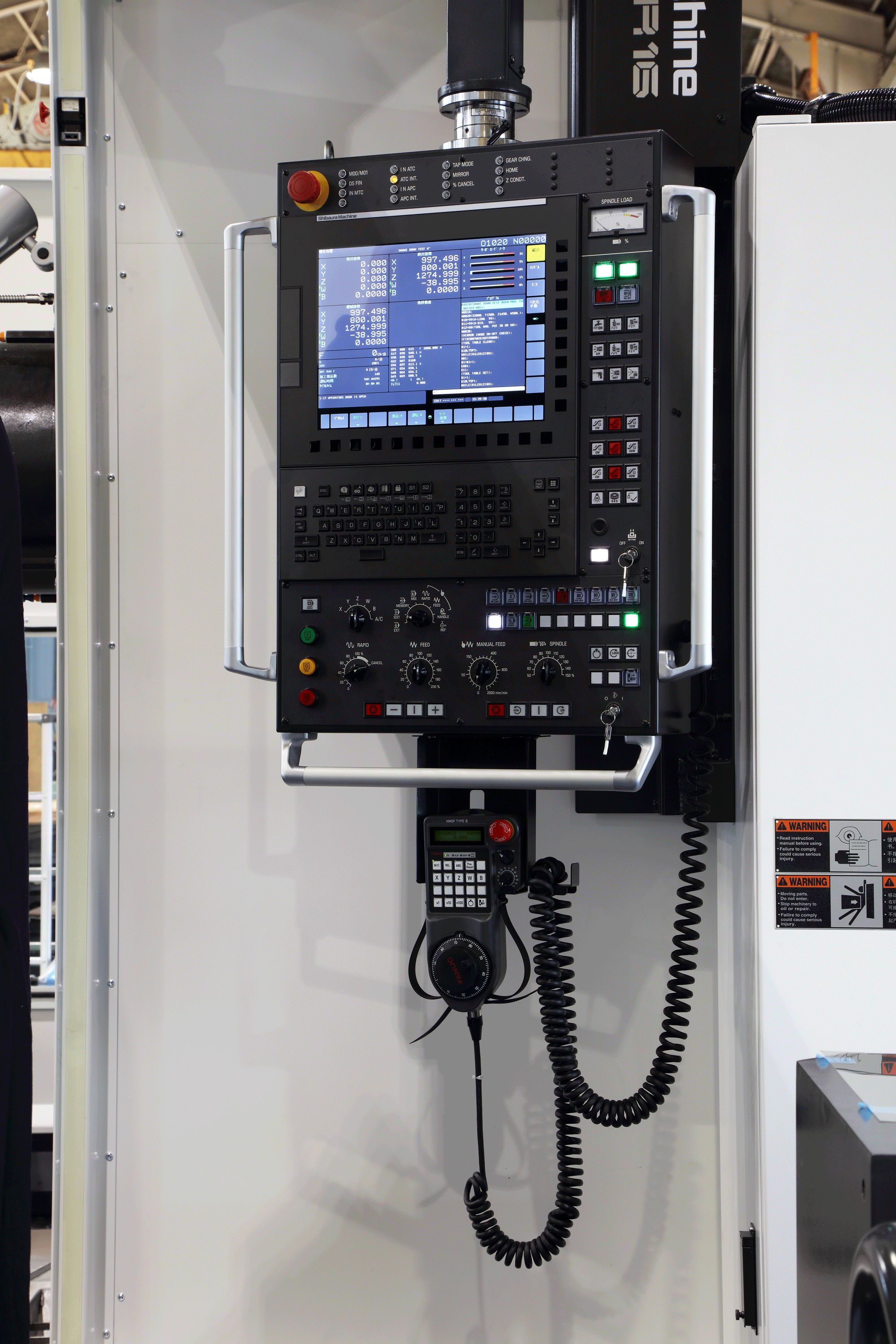

| Control | FANUC 31i-B Plus |

Rotary Milling Function

Cylindrical and end surfaces can be machined continuously by the B-axis continuous indexing function, eliminating the need for an optional independent-type NC rotary table. Cylindrical surface machining is easily programmed in the manual programming by the cylindrical interpolation function

Portable Handwheel feed unit (X, Y, Z, W, B-axes)

Manual operations relating to machine movements are separated from the NC operation unit and centrally arranged on the pendant operation box. Thus, combined NC and manual machining operations can be performed smoothly

Scale feedback on X, Y and Z Linear axes, and B Rotary axis.

All linear axes and rotary axis are designed with servo drive mechanism in order to achieve high rigidity and high accuracy

Automatic measuring RENISHAW probe and calibration block (Optional)

This unit consists of a radio touch probe made by Renishaw, a standard measuring software designed by Shibaura Machine and calibration block for checking compensation value of touch probe

Automatic Tool setting RENISHAW RTS probe (Optional)

This unit consists of RTS probe made by Renishaw to measure tool length and compensate value of tool offset