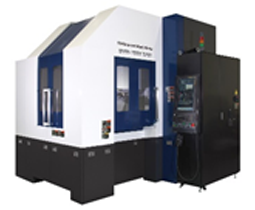

UVM-700E(5AD)

High Precision Machining Center UVM Machine

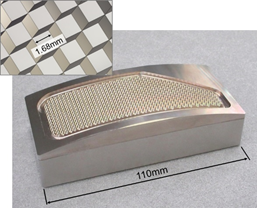

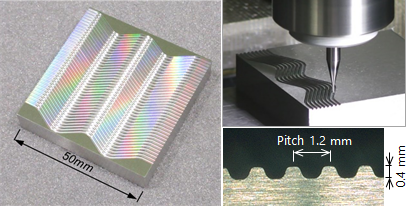

UVM Series has been developed with the concept of high speed and high quality machining, providing High Precision Aerostatic Bearing Spindle. This is a high precision machine and one of application targets is a precision mold.

X Stroke - US Standard (in)

Y Stroke - US Standard (in)

Table Size (WxL)- US Standard (in)

Max Load - US Standard (lbs)

| X Stroke inch(mm) | 31.8 (810) |

|---|---|

| Y Stroke inch(mm) | 31.5 (800) |

| Z Stroke inch(mm) | 13.8 (350) |

| A-axis (degree) | -90 ~ +90 |

| Spindle (rpm) | 60,000 |

| TABLE size inch(mm) diameter | 19.7 (500) |

| Max. load lbs (kg) | 440 (200) |

| Control | FANUC 30i-B |

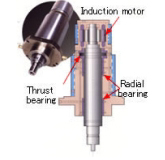

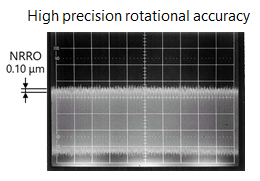

High speed aerostatic bearing spindle

Spindle speed: 60000 min-1

NRRO(*): 0.10 μm

TIR: 1 μm

(*) Measured with the method of Single Point Asynchronous Error Motion

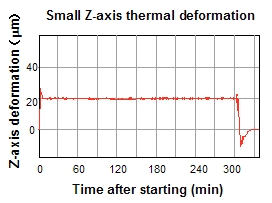

High speed and low heat generation

- Improvement of machining time

- Reducing in the types of tools and the processes (small diameter tool use)

- Low spindle thermal displacement (See the figure at right)

Virtually unlimited life of bearings

- Availability of high speed, continuous machining

- Reduction in the maintenance cost

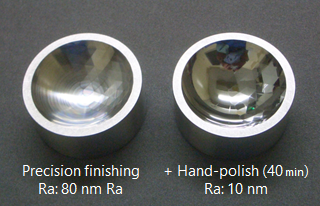

Low level vibration and noise

- Realization high quality machined surface

- Improvement of the working environment

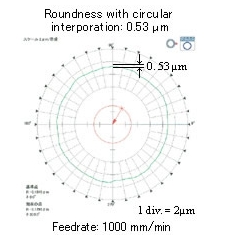

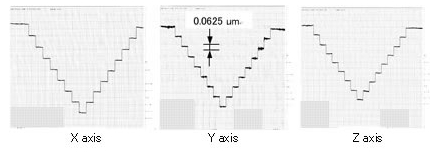

High precision contouring

High quality surface machined with high speed feedrate is realized, providing linear motor driving system for X, Y and Z axis.

- High quality and smooth machining around quadrant switching area realized, due to minimized lost motion.

- High quality flat surface realized, due to eliminating factors, for instance, influenced by a ball screw driving system.

Linear motor drive High precision positioning and smooth feed

Reliable step feed 0.1 μm realized, providing 0.01 μm of programming resolution for X, Y and Z of linear 3 axes.

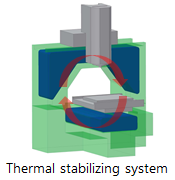

Efficient cooling system

UVM-450D(H), UVM-700E(5AD)

Thermal stabilizing system allows high-precision machining for long hours.

Circulates a temperature-controlled liquid through the structure.

FormEye

Tool profile measurement device: FORM EYE

Measurement function: Tool length measuring

Min. tool blade diameter: φ0.05 mm.

The extended function linked with UVM-TSA:

Tool diameter measuring, Measurement for spindle displacement, Measurement for tool shape.

The tool diameters where tool profile measurement is possible are 0.1 mm to 3 mm.

UVM-TSA

Integrated support software for UVM (UVM-TSA)

It is the software for to expand or setting automatic tool length measurement device (Dyna Line, FormEye) and touch sensor that is optional accessories.

Extended functions:

① Automatic tool length measurement device

Measurement for Tool length, diameter, tool shape, spindle displacement, dynamic run-out retry function

Note: This function reclamps the tool when dynamic run-out was detected.

② Touch sensor

Coordinate setting, shape measurement(circle, quadrilateral, groove, aspheric surface One-touch, multi-point)

Note: Depending on the workpiece shape, measurement may not be possible.

③ Tool management

Tool lifetime management, Tool Information management