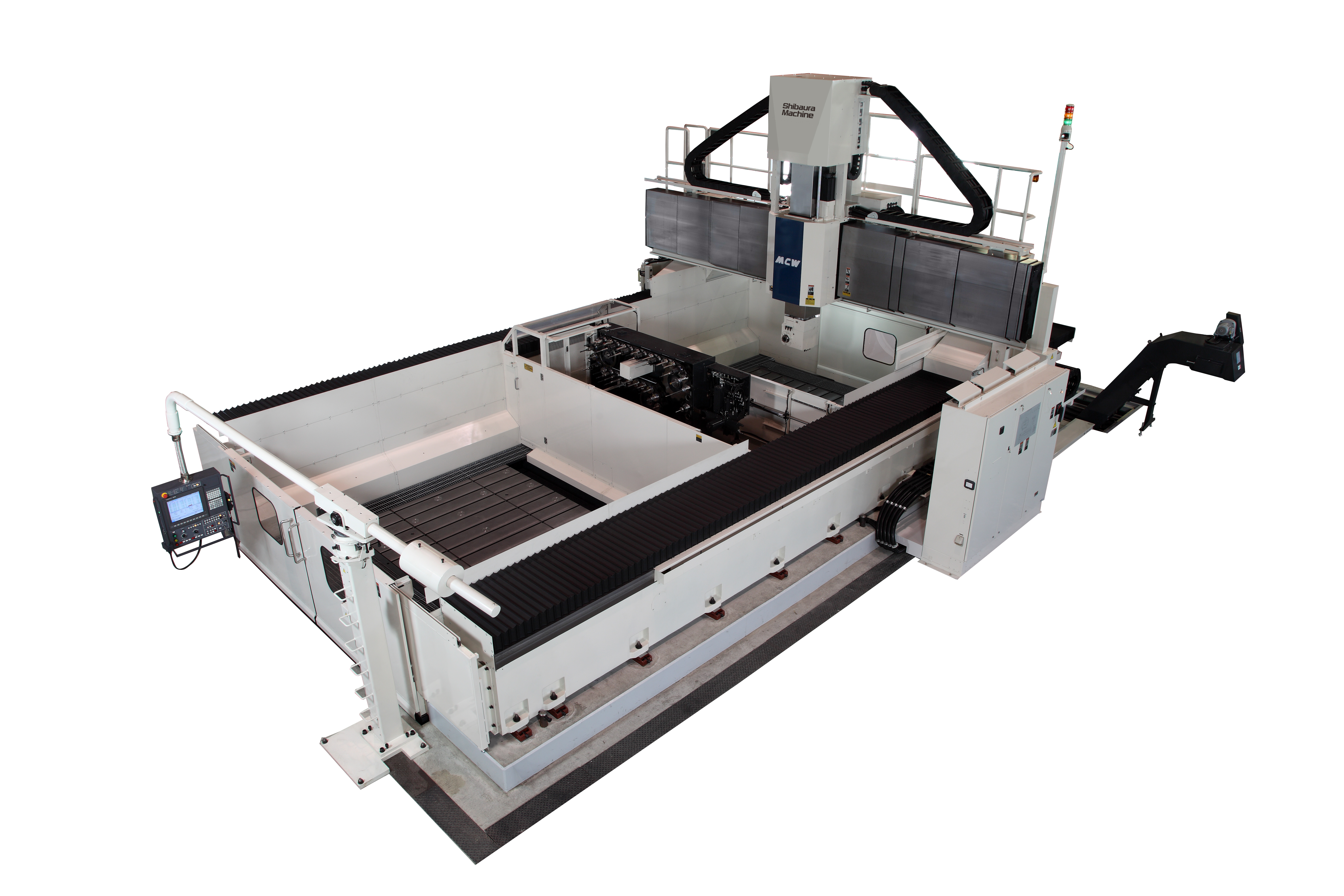

MCW-4624

Double Column Type Machining Center MCW Machine

The MCW-4624 is a new gantry double-column machine that assures higher productivity & performance in large heavy parts which require high stock removal in precision tooling for automotive and aerospace industries.

Contact Shibaura to learn more!

X Stroke - US Standard (in)

Y Stroke - US Standard (in)

Table Size (WxL)- US Standard (in)

Max Load - US Standard (lbs)

Spindle RPM US Standard

| Distance Between Column inch(mm) | 180.3 (4580) |

|---|---|

| Height inch(mm) | 53.5 (1354.8) |

| X Stroke inch(mm) | 137.8 (3500) |

| Y Stroke inch(mm) | 145.7 (3700) |

| Z Stroke inch(mm) | 35.4 (900) |

| Spindle (RPM) | 4000 |

| TABLE size inch(mm) | 126 x 94.5 (3200 x 2400) |

| Max. load lbs(kg) | 2,048lbs/sqft (10000Kg/m2) |

| ATC Tool Pod | 60 |

| Control | TOSNUC PX-100 |

BIG PLUS, 5-face cutter head designed for AATC

Standard 5-face cutter head is designed and manufactured for the tool shank of BIG-PLUS. (AATC, AAI compatible)

Automatic attachment indexing device (AAI - 5degee or -1degree)

There are two ways for program as bellow. Automatic indexing at every 5 degree or every 1 degree: M37C. When selected three-dimensional coordinate conversion in CNC: G37C.

Table Lubricant Oil Cooling unit

The bed is made of cast iron, having rationally arranged ribs to completely support the table. Additionally, a thermally symmetrical design and a standard equipped lubricant oil cooling unit contribute to minimize thermal distortion to realize a high thermal-rigidity structure

SHAPE recognition preview control function (CNC SHAPE)

Shape recognition preview positioning control (CNC shape II). Target are accurate shape and smooth surface in contouring surface machining.

Automatic measuring RENISHAW probe

This unit consists of a radio touch probe made by Renishaw, a standard measuring software designed by Shibaura Machine and calibration block for checking compensation value of touch probe.

Automatic Tool length measuring unit (BLUM) for vertical spindle only

This unit is located at the left corner of floor plate. Only vertical spindle center point tools correspond. Reference tool for calibration is excluded.

Automatic measuring RENISHAW probe (Optional)

This unit consists of a radio touch probe made by Renishaw, a standard measuring software designed by Shibaura Machine and calibration block for checking compensation value of touch probe

Automatic Tool setting RENISHAW probe (Optional)

This unit consists of a Renishaw probe to measure tool length and compensate value of tool offset

Download

1.40 mB