EC390SXIII All-Electric Injection Molding Machine

- In Stock

All-Electric SXIII Series Machine

With the EC390SXIII All-Electric Injection Molding Machine, molders get an all-electric injection molding machine that delivers fast injection speeds and dry cycle times, ensures longer mold life and provides more uniform clamping force, for greater productivity, flexibility, and versatility, job after job.

Tonnage - US Standard (US Tons)

Tie Bar Distance (HxV) - US Standard (in) 1

Platen Dimensions (HxV) - US Standard (in)

Injection Capacity (PS) - US Standard (oz)

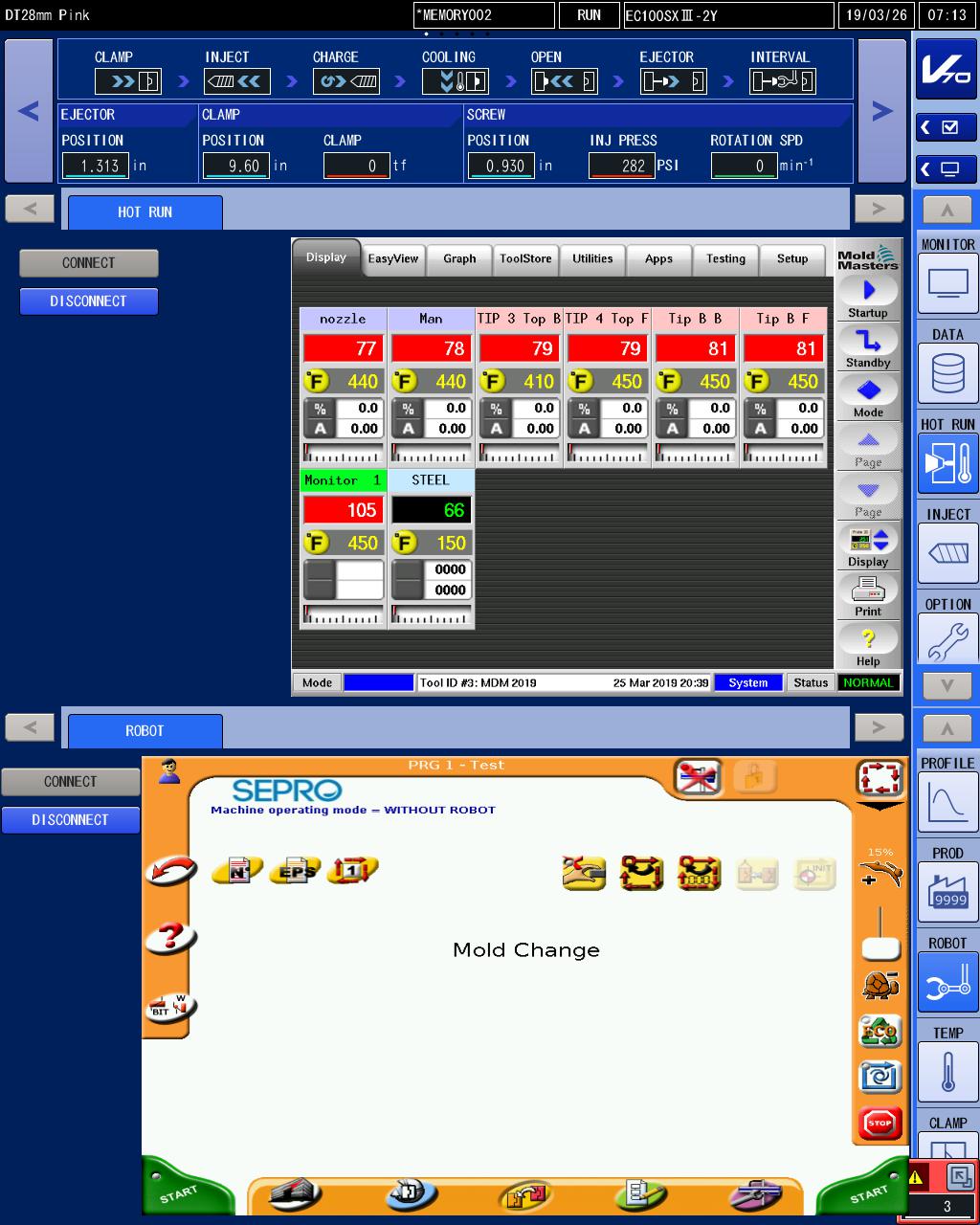

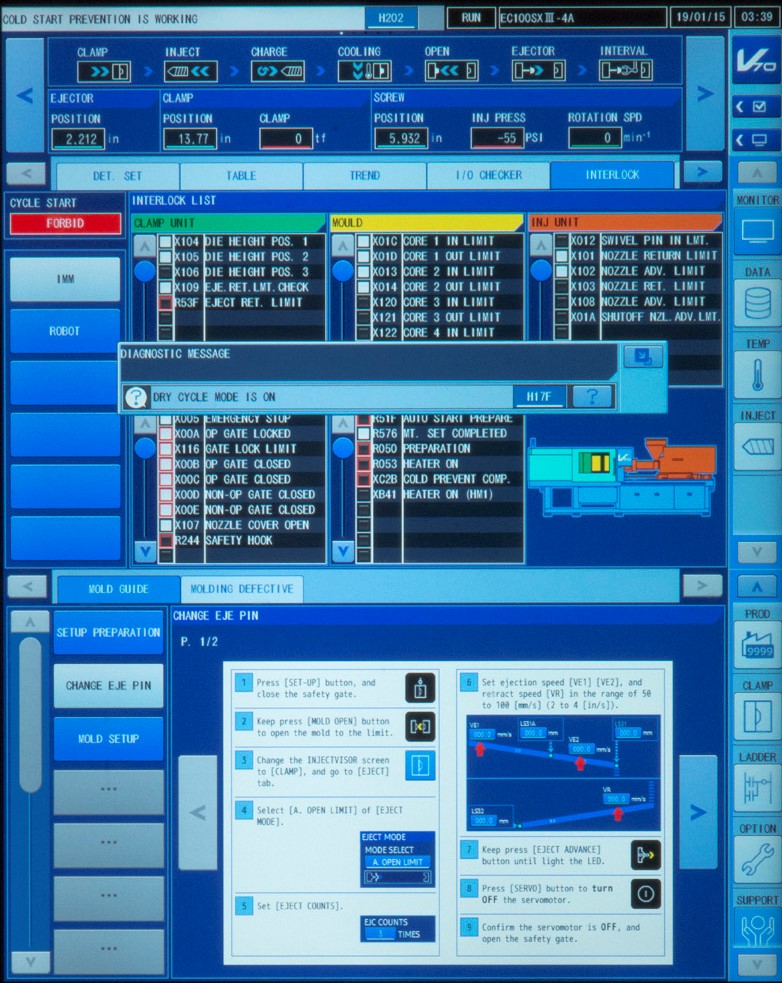

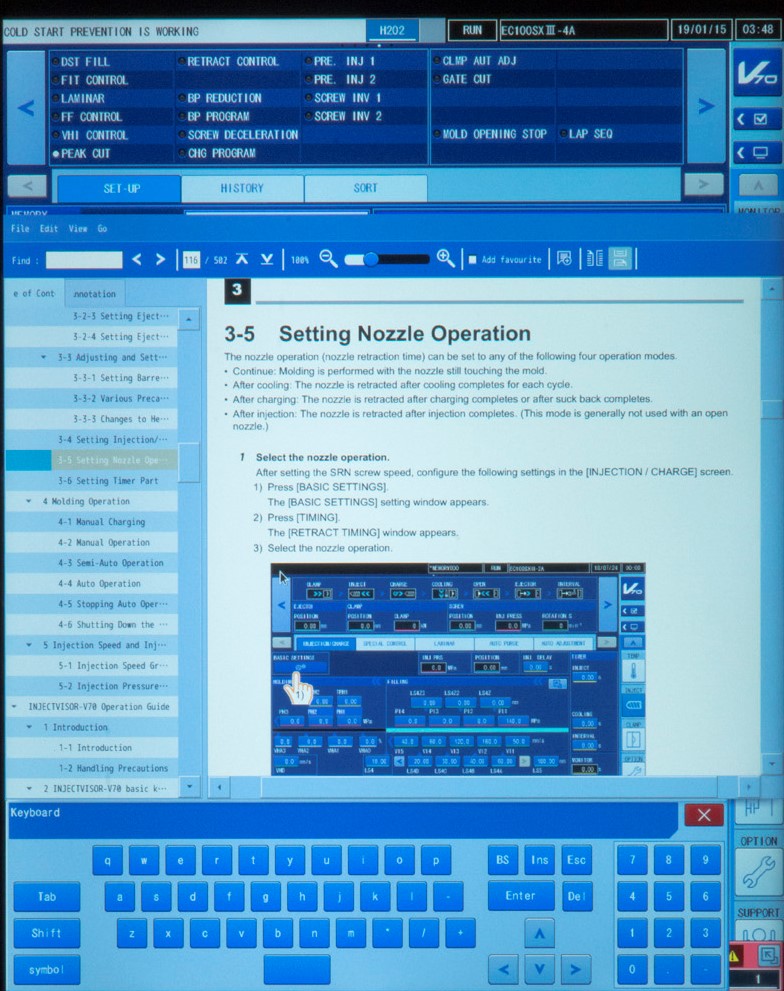

V70 Controller - 19" True Split Screen with Touch/Swipe Functionality

With the new Injectvisor V70, you get a controller designed with the smart factory in mind, one that’s capable of integrating with auxiliary equipment via OPC-UA communication. Packed with new tools for speeding up mold set ups, optimizing cycle times, analyzing part defects, troubleshooting molding defects and more, giving you a faster payback on your machinery investment.

Dual Hydraulic Core Pull Program & Electrical Interface

Our machines come equipped with dual core pull programming and interface. Portable hydraulic power units are sold separately, but can be added at any time. Our portable hydraulic units simply plug into the standard interface, for easy, "plug and play" use.

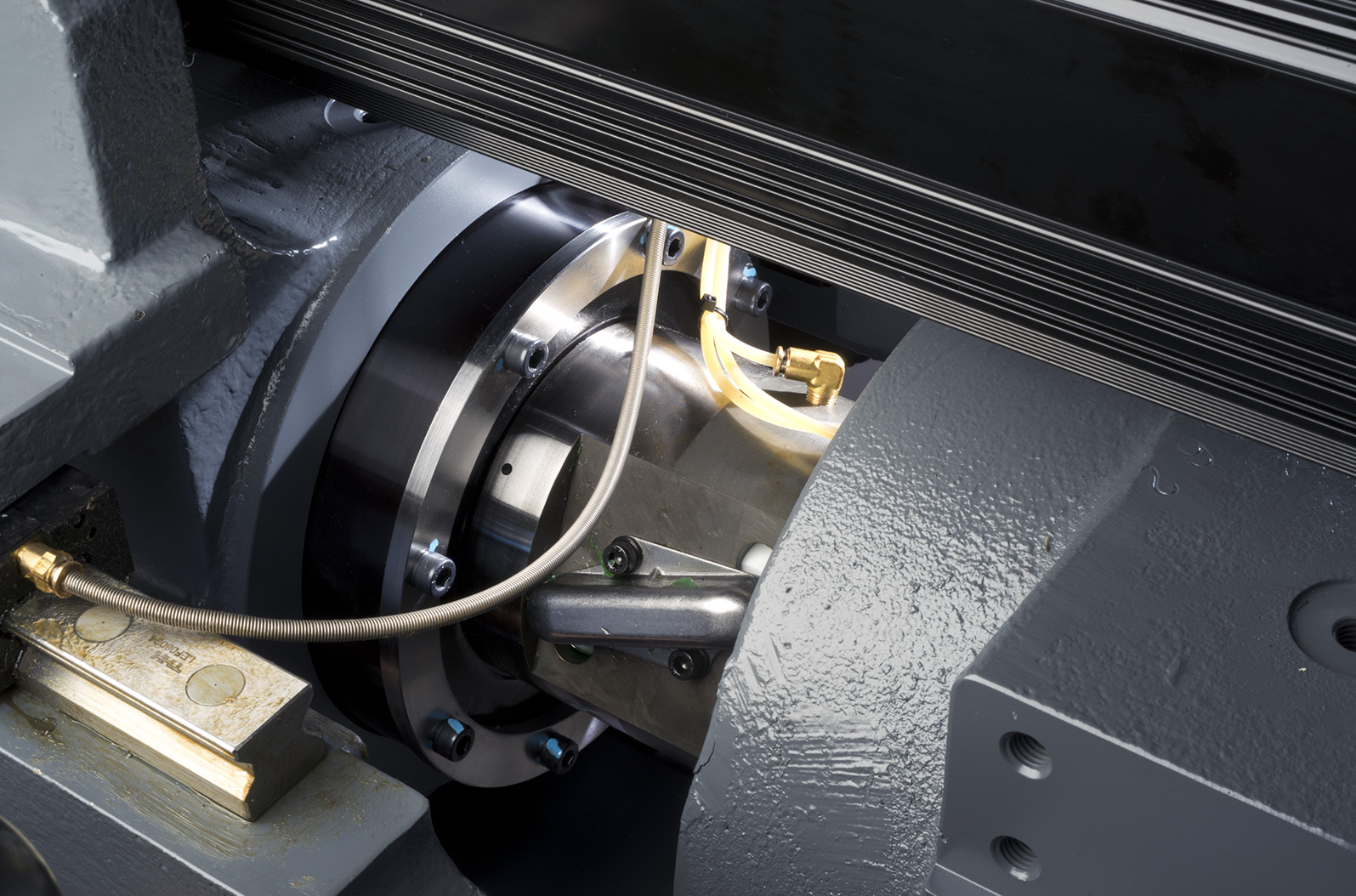

Bushing Free, Grease Free Tie Bars

With bushing-free, grease-free tie bars, there's less chance of contaminating molded parts, increasing your shop's quality.

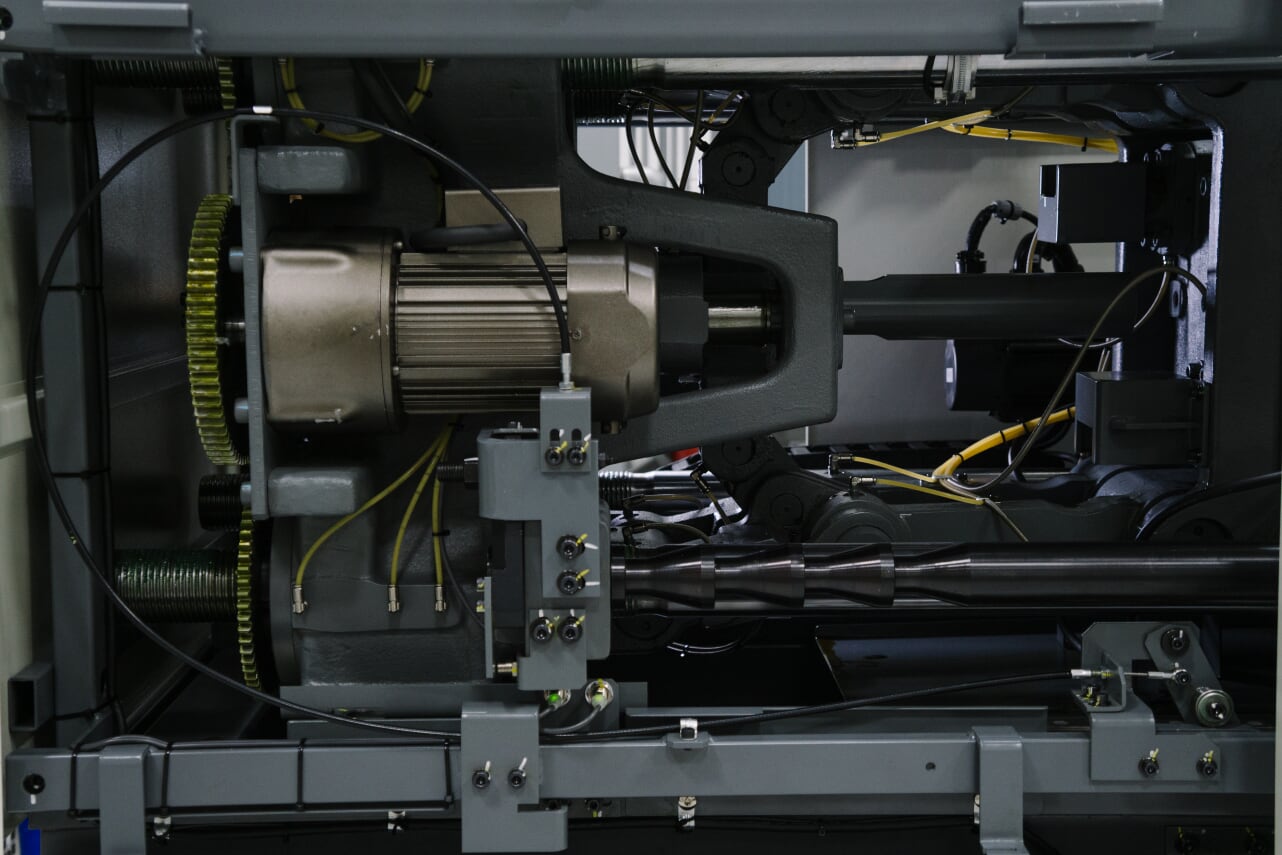

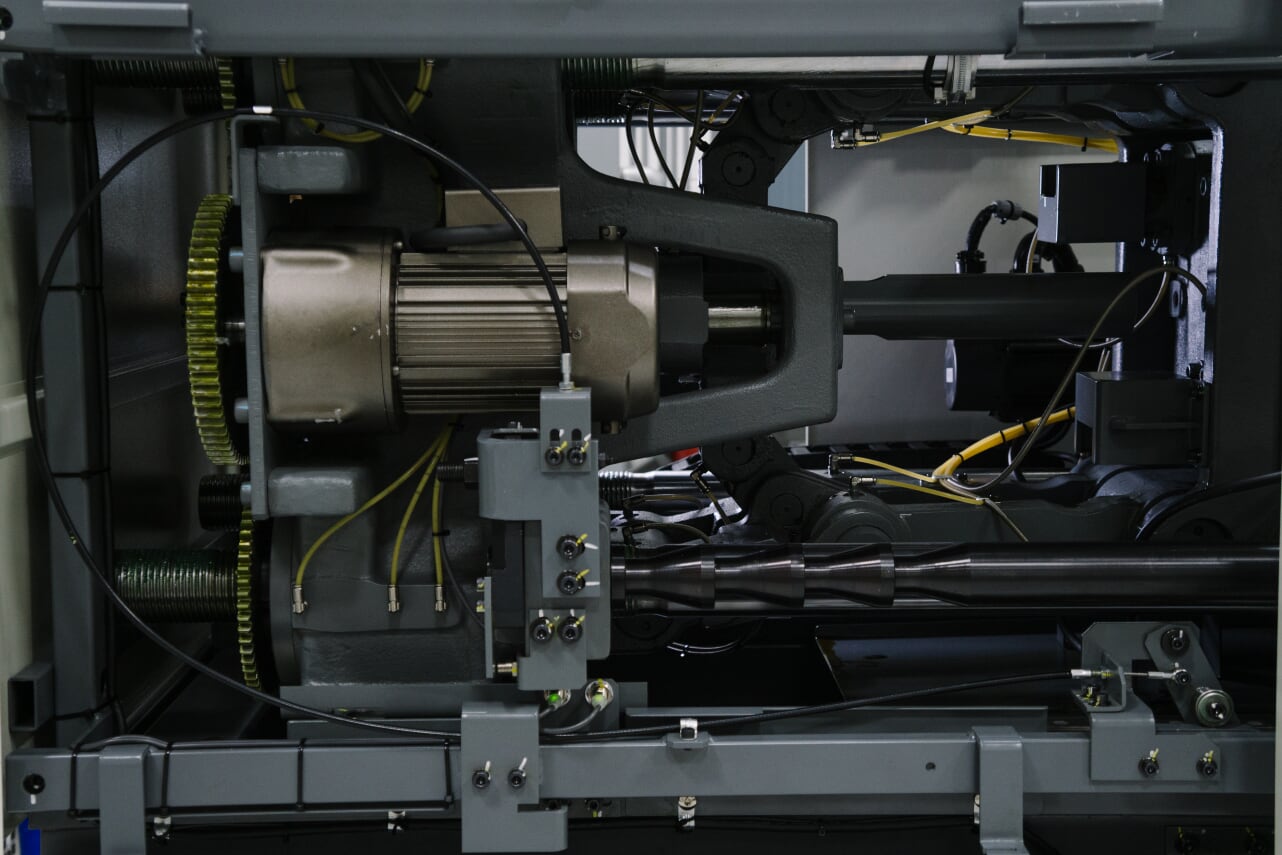

Linear Guides for Rigid, Precise Machine Movements

On the moving platen, linear guides are used instead of tie bar bushing to ensure steady, precise movement. This friction free drive system is also used on the injection unit to ensure more accurate injection speed and back pressure control. This ensures shot-to-shot repeatability over the life of the machine.

SPI Robot Interface Receptacle

Shibaura ECSXIII machines come equipped with a Euromap 67 (50 pin) robot interface receptacle. Euromap 12 (32 pin) robot interface is also available.

Auto Tonnage Adjustment via Strain Gauge on Tie Bar

This feature utilizes a strain gauge on the tie bar to monitor actual tonnage. Tonnage can be automatically adjusted on-the-fly to ensure accurate tonnage at all times. This prevents over-tonnage as the mold heats up and expands, helping to prevent mold damage and early tool wear.

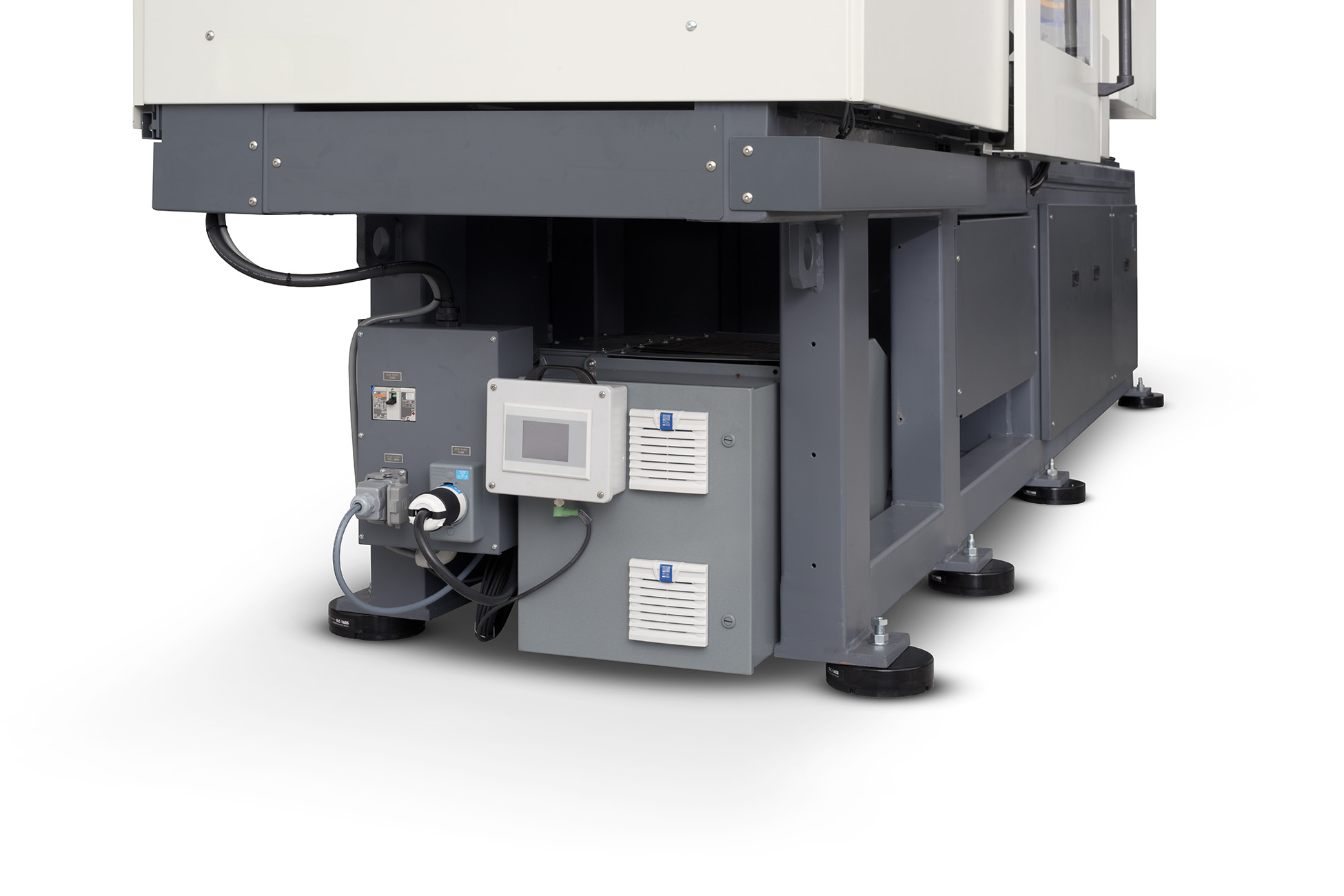

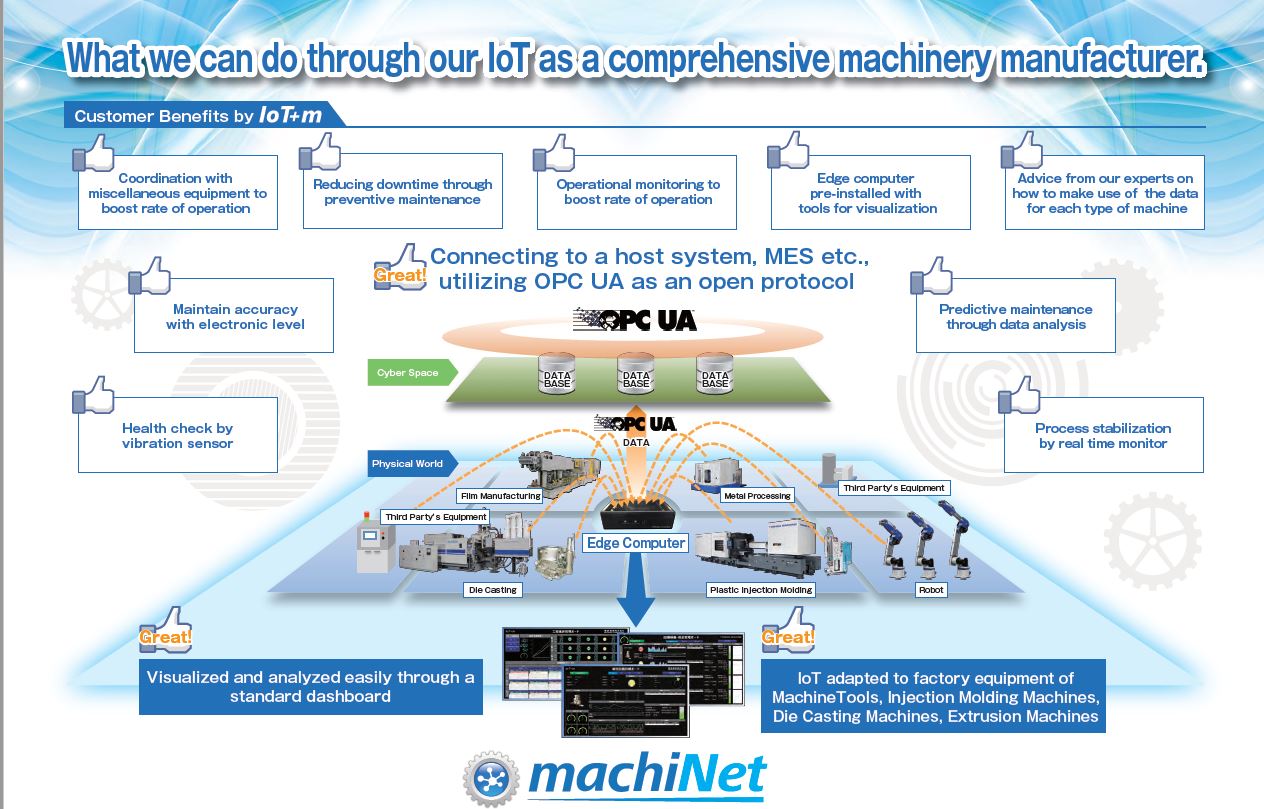

Auxiliary Equipment Integration Available

The OPC-UA architectures of our V70 controller allows the possibility of integration with ancillary equipment as well as potential data communication with plant ERP and MES systems.

5-point Linkline toggle mechanism - even force distribution, extended mold life, and reduced maintenance

The ECSXIII's 5-point Linkline toggle mechanism is angled to distribute force evenly across the platen, increasing quality and minimizing defects. It has the added benefit of extending mold life and reducing machine maintenance.

Dual Air Blow

Shibaura machines come equipped with dual air blow for help with ejecting difficult parts.

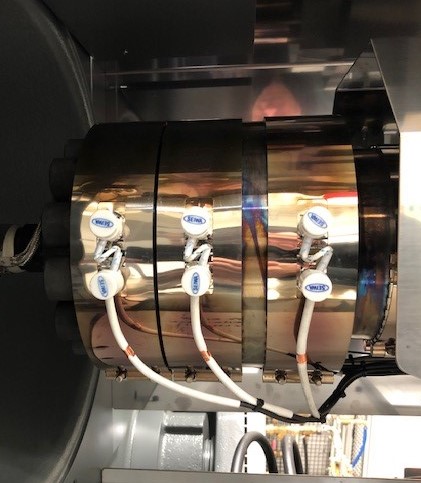

Heater Band Failure Alarm

This feature allow you to quickly identify a failed heater band and replace it quickly. With competitor's machines, first the process suffers as a particular heat zone struggles to maintain temperature. Once someone recognizes that there is likely a failed heater band, they must then test each band within that zone to determine which one is bad.

Single Pneumatic Core Pull (timer only) and Single Pneumatic Valve Gate

Single Pneumatic Core Pull, timer only & Single Zone Pneumatic Valve Gate

OPC-UA Communication

With its OPC-UA open architecture supporting Euromap 63 and Euromap 77 communication, wide range of auto-correcting functions and more, the V70 is the most powerful, flexible tool on the market for achieving your vision of Industry 4.0..

Molding Support Function

On-screen help functions for inexperienced molders to assist with setting a new tool as well as diagnosing and overcoming common processing defects.

On Screen PDF Manual

The machine manual is now located in the on-board PDF library. It is easily access and is searchable.

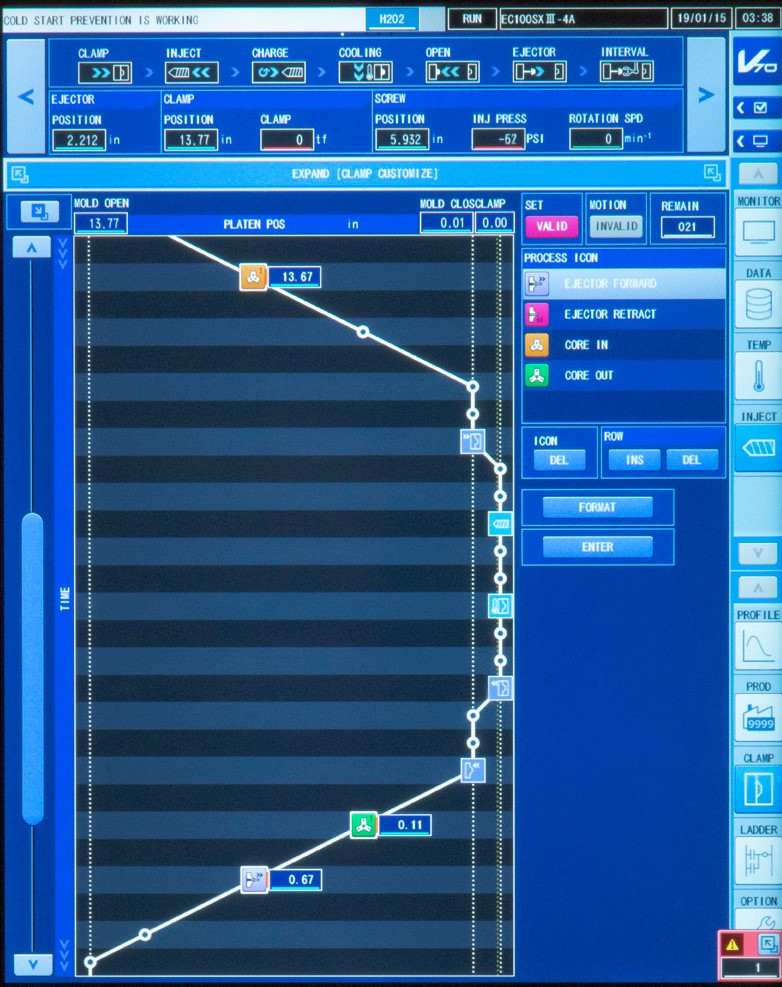

Drag/Drop Clamp Sequence Customization

New graphic interface allows you to drag and drop icons to create a custom clamp open and close sequence. Data is saved and confirmed at set-up, resulting in fewer errors, less mold damage, and increased productivity.

I/O Checker & Machine Interlocks

I/O Checker - This screen shows all machine inputs and outputs, each of which are labeled with a description for easy troubleshooting.

Machine Interlock Screen - This page shows all of the machine interlocks, color coded by section of the machine and the current status of each. There is also a section showing the robot interlock in detail with current status.

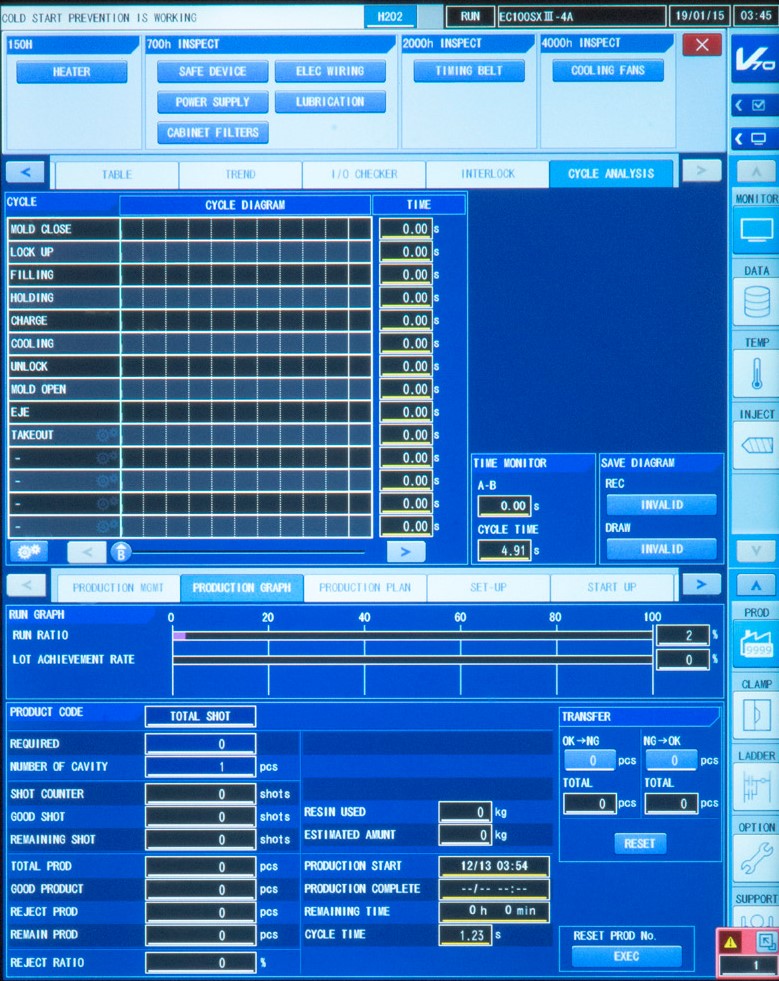

Cycle Time Analysis

Cycle Time Analysis tool creates a template of each segment of your cycle. Each shot overlays each segment so you can visually see where you might be losing time or if there are opportunities to save cycle time.

History Screen

The V70 features a history screen with tabs for Set History, Alarm History, and Stop History.

- Set History - Used in conjunction with the user log-in feature, You can see the last 1,000 changes made - the old setting, the new setting, and who made the change.

- Alarm History - The last 1,000 machine alarms

- Stop History - The last 1,000 time the machine stopped, and why.

Specifications

0.08 mB