S-Concept

Next-Generation Molding Machine to Achieve Even Higher Productivity, Labor Savings, and Environmental Friendliness

EC55SXIII to EC390SXIII ONLY

Save Time

Industry's Fastest Clamp Design Featuring Both High Productivity and Clean Environment

Moving platen linear guide support structure for smooth mold opening/closing motion and improved linearity paired with double rigid plates and link line toggle for uniform distribution of clamping force. The design includes dynamic acceleration/deceleration control (Shibaura Machine patented technology) for achieving both high-speed mold opening and closing and reduced shock.

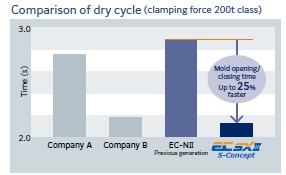

Fastest Dry Cycle Time

Enabling shorter cycle times without impact on the quality while maintaining the same molding conditions as before Compared to previous generation, cycle time can be shortened by up to 168 hours per year* *For the same injection conditions, 200 hours of production per month, and a cycle time of 10 s. *Adjustments may be required depending on the customer's production system.

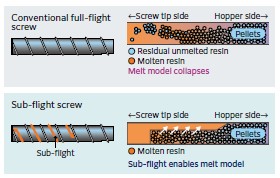

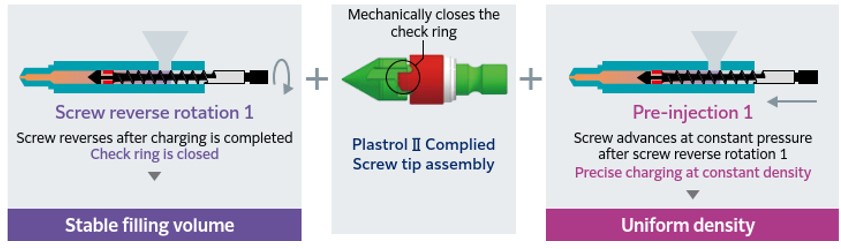

S-Cube Injection Unit for Stable Plasticization and Filling

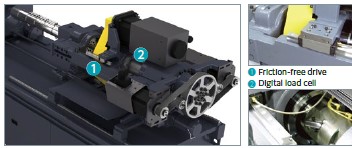

The S-Cube injection unit features a friction-free drive that minimizes sliding resistance, noise-resistant digital loads cell that improves pressure detection accuracy, linearization compensation that eliminates variation between machines, and a high-output motor that enables the industry's top pressure holding capacity.

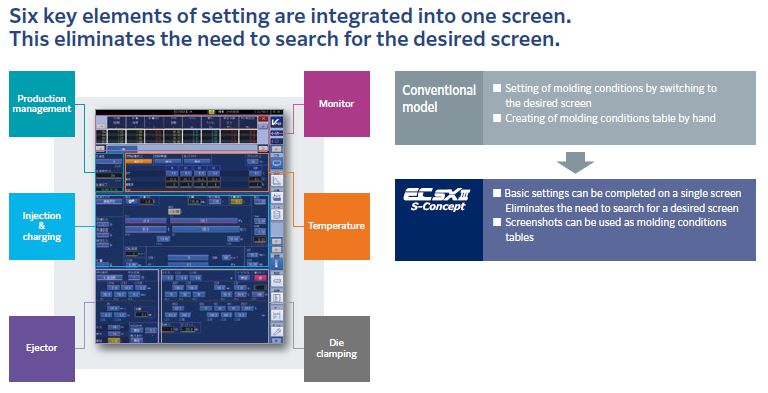

Save Labor

Environmentally Friendly

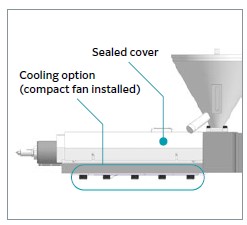

New Heater Cover with Both Heat Retention and Cooling Performance (Coming in 2025!)

Enclosed cover structure for improved heat retention and energy-saving performance reduces annual CO2 emissions by 24% while reducing the barrel cooldown time by 60% resulting in significant productivity increases. COMING IN 2025 FOR NEW MACHINE ORDERS. AVAILABLE IMMEDIATELY FOR RETROFITS OF EXISTING SXIIIV70 MACHINES.

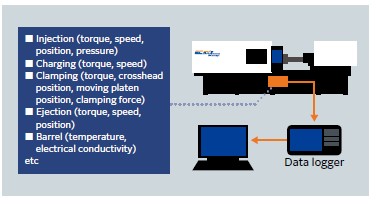

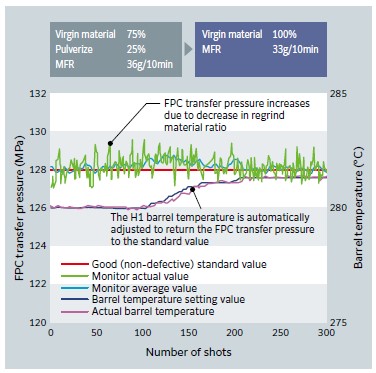

DST Fill for Automatic Material Viscosity Compensation

Viscosity changes caused by changes in the mixing ratio of regrind materials can lead to molding defects such as short shots and flash. Viscosity changes are detected by monitoring data such as FPC transfer pressure, and conditions such as barrel temperature and are automatically adjusted to keep the viscosity constant and prevent molding defects. This allows processors to use more regrind materials.

V70 Power Consumption Monitor

Displays power consumption (calculated value) of molding machine. It shows current and cumulative power consumption, trend graph for a specified period, electricity fees, etc. Power usage data can be saved to a USB flash drive. Backup data for the past year can be loaded.