DC350R-H/EH

- (New version, DC400R2 in 2025)

Small DC-R Machine

The DC350R-H/EH series uses a technologically advanced interchangeable modular method.

By changing the combination of four proven technologies on the injection end; R-M machines=standard servo hydraulic + hydraulics die locking, R-EM machines=standard servo hydraulic + optional servo die locking, R-H machines=super high-speed servo hydraulic injection + hydraulics die locking, R-EH machines=super high-speed servo hydraulic injection +optional servo die locking, along with the appropriate base frame we can support the production of a complete R-series line of very productive and reliable machines.

SHIBAURA MACHINE believes it should always continue to be innovative while preserving technologies of proud and proven traditions.

Contact Shibaura to learn more about our DC 350 machine!

Machine Die-Locking Force - Metric (Metric Tons)

Tie Bar Clearance Distance (HxW) - Metric (mm)

Injection Speed - Metric (m/sec)

Die Thickness - Metric (mm)

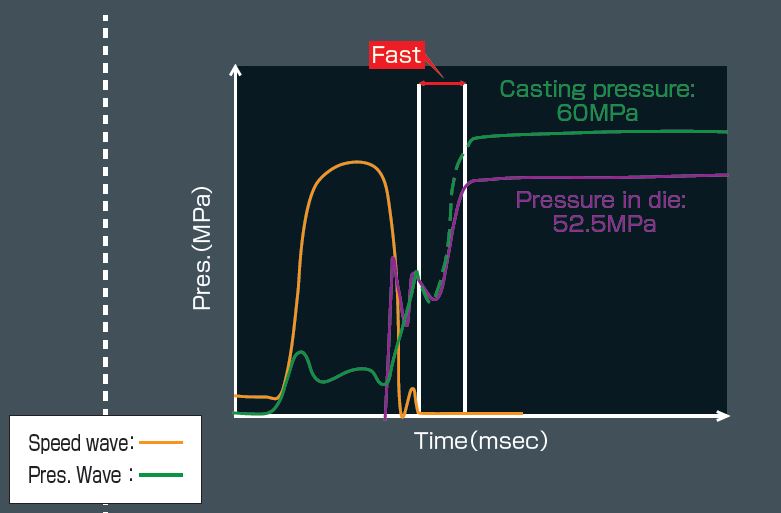

Better Pressure Buildup

Shibaura Machine has succeeded in reducing the pressure buildup time by improving the hydraulic intensification circuit.

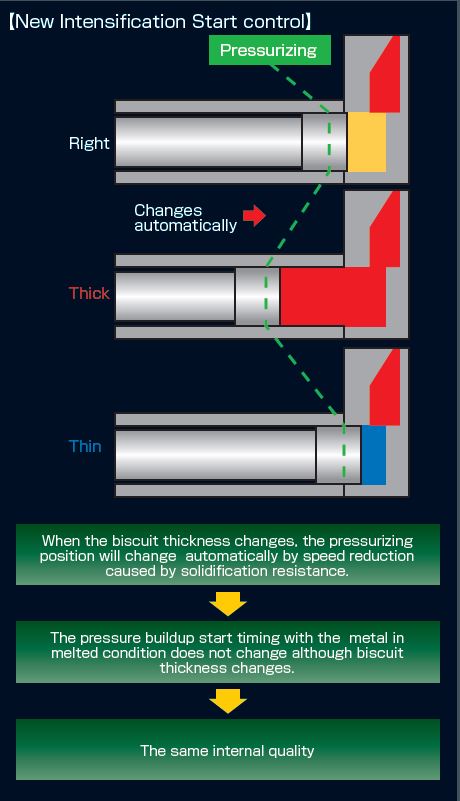

Intensification start control

Compared with the conventional position-based start control, the new control system has been developed to start the intensification always at the same timing even with the ladling volume variation. It is effective in case of higher fast shot speeds and/or using the slowdown control.

Acceleration ability

Shibaura Machine worked on improvement of short time filling and short time intensification, which mostly improves the quality of cast products.

In the R- series, the standard injection and high grade servo injection are realized for performance improvement of the conventional machine.

We propose an optimal injection mechanism for each required quality.

- 100G represents the capability to accelerate to 10 m / sec at 10 msec.

Increased Die-Locking Rigidity

While the production bases are getting globalized, even in a different manufacturing environment, the same production efficiency is required as in the main plant.

Based on the know-how obtained from tours of many customers domestic and international, the conventional die-locking rigidity was changed and the new die-locking system that enables high productivity even under harsh environments was developed and put on the R-series.

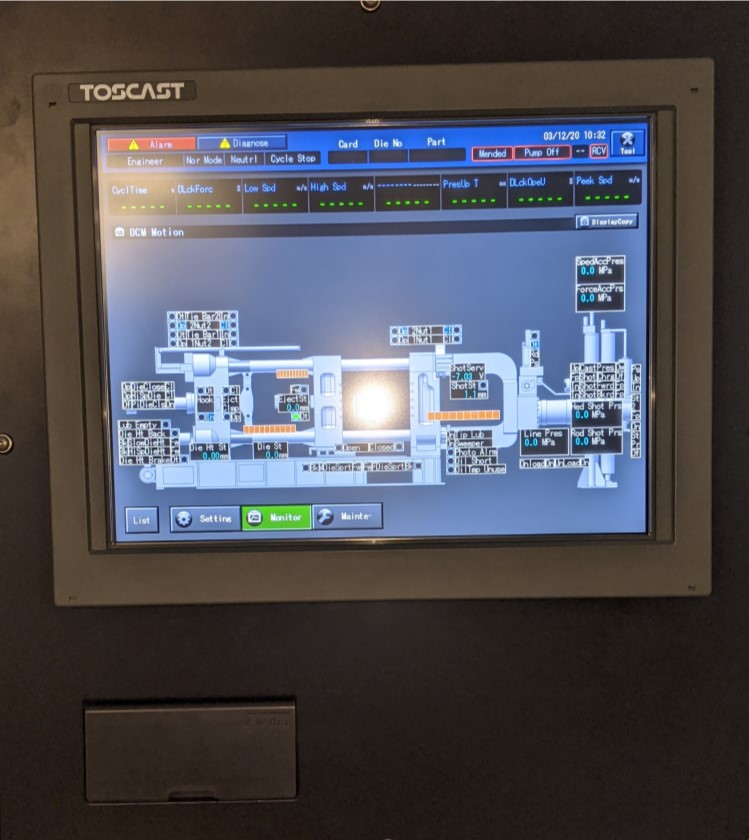

Controller (TOSCAST-888)

All machine models come with an advanced controller (TOSCAST-888) as a standard feature. Thanks to the large 15-inch screen, the human-machine interface based on ergonomics, the operator’s maintenance/management environments are improved. The multilingual capability and input restriction control are possible to help improve the global production control efficiency.

In addition, it includes as standard the trouble diagnostic functions by the SHIBAURA MACHINE’s own technology, and together with the host communication (optional) helps improve the maintenance ease and production efficiency.

Operator’s touch panel layout

To improve the operational ease on R series machines, a 12-inch touch-screen display is situated at the operator’s station.

The buttons and switches control all machine functions, making the operational user friendly.

Line display

Besides the standard 48, selected from a list of over 200, items can be viewed on the Line Display, 16 temperature points can be monitored and viewed.

All of these contribute to your quality control and help increase acceptance rate.

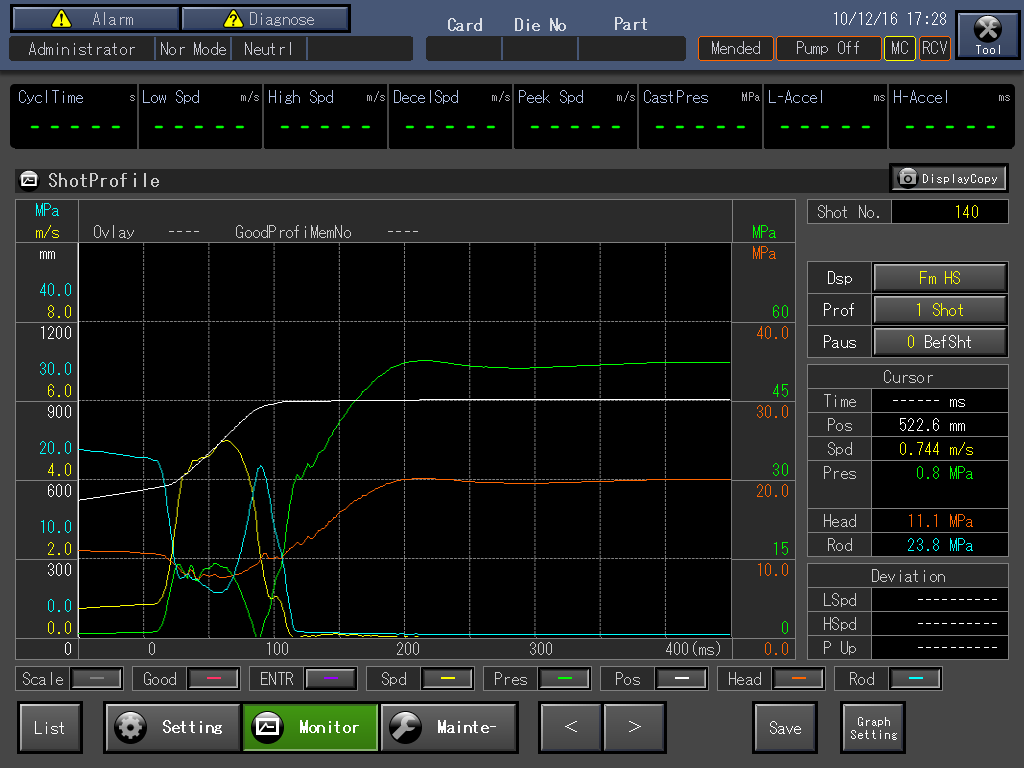

Injection waveform

Possible to view vacuum and position waveform simultaneously.

In addition to the vacuum, a different waveform can be added.

All of these contribute to your casting analysis and help improve your casting technology and acceptance rate.

Password function

Passwords assigned to individuals will limit the pages and information that can be accessed.

Control alarm occurrence

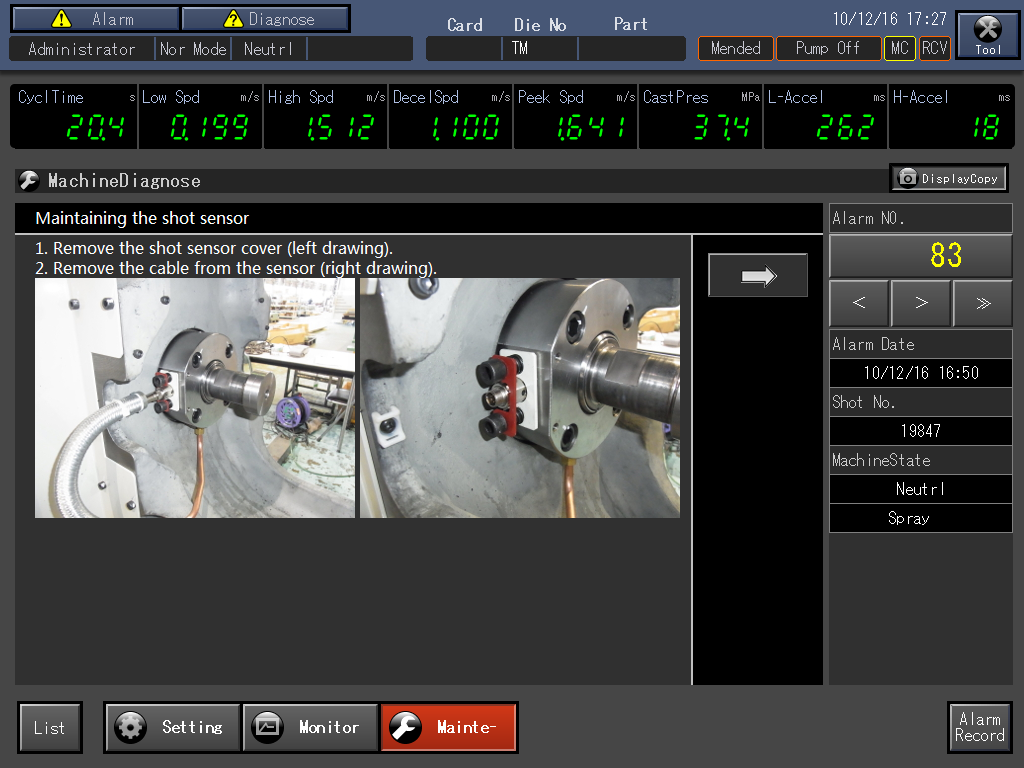

On alarm occurrence the causes are made visible to save time of restoration. ・On alarm occurrence the causes are indicated including the location (by photograph/drawing), what to check and how to check.

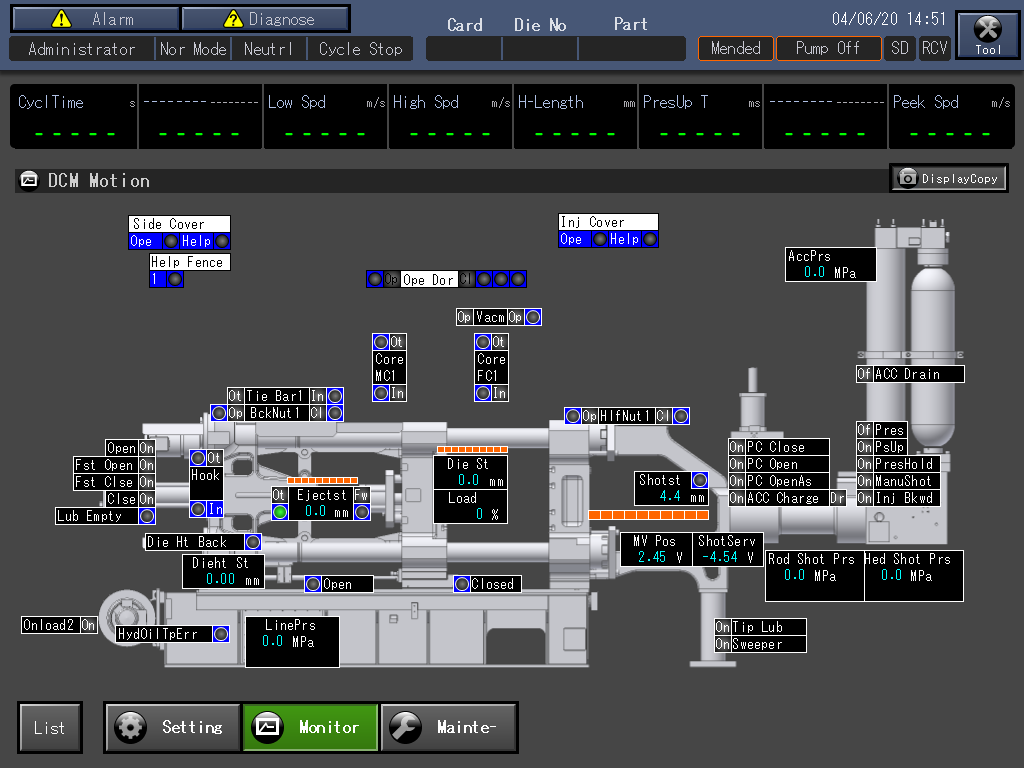

On / Off Status display of the sensors, solenoids, and limit switches

This TOSCAST-888 display shows an operation monitor screen of the die cast machine showing the current ON / OFF status of the sensors, solenoids, and limit switches.

PLC circuit-monitoring function

PLC circuit can be monitored in real time, on TOSCAST screen; effective in trouble shooting.

●This is available on Shibaura Machine's advanced TC200 Sequencer

●Real-time monitoring is possible without connecting to a PC.

●Designations of contacts are written in Japanese or English.

●For safety’s sake the values and/or logic cannot be changed.

Automatic Ladle Device

HIGH ACCURACY LADLE DEVICE

Responsive to the growing needs for the importance of quality control, we have perfected the servo controlled ladle device that has increased the ladling quantity accuracy.

The servomotor drive both for the traveling and pouring axes achieves excellent stop position

accuracy and stable motions.

The use of a timing belt for the upper part of pouring drive transmission, and a double-roller

chain for the lower part achieves a smooth motion.

Maintenance and Trouble shooting are simplified because this device is controlled and monitored by the same control as the machine. This eliminates the need for an additional or external PLC to maintain.

Automatic Spray Device

SPRAY DEVICE FOR NEXT GENERATION, READY FOR HIGH QUALITY CASTING

Responsive to the growing needs for the importance of quality control, we have perfected the servo controlled Automatic Spray Head DBS*LR promotes die casting quality improvements and cost reduction!

Driven by the epoch-making fast cycling servomotor;loaded with the optimum spray head!!

The servomotor drive both for the traveling and positioning achieves excellent stop position accuracy and stable motion.

Maintenance and Trouble shooting are simplified because this device is controlled and monitored by the same control as the machine. This eliminates the need for an additional or external PLC to maintain.

Automatic extractor

FAST-CYCLE TAKE-OUT DEVICE

Being simple and sturdy with speed and stability.

The simple operation enables easy presetting of the operational positions for each die.

The take-out device of a horizontal robot type with high performance has come into existence!!

High Accuracy and Speed with this Servo controlled Device.

The SCARA robot technology developed in our company achieves the excellent stop position accuracy, speed, and stable motion.

Maintenance and Trouble shooting are simplified because this device is controlled and monitored by the same control as the machine. This eliminates the need for an additional or external PLC to maintain.

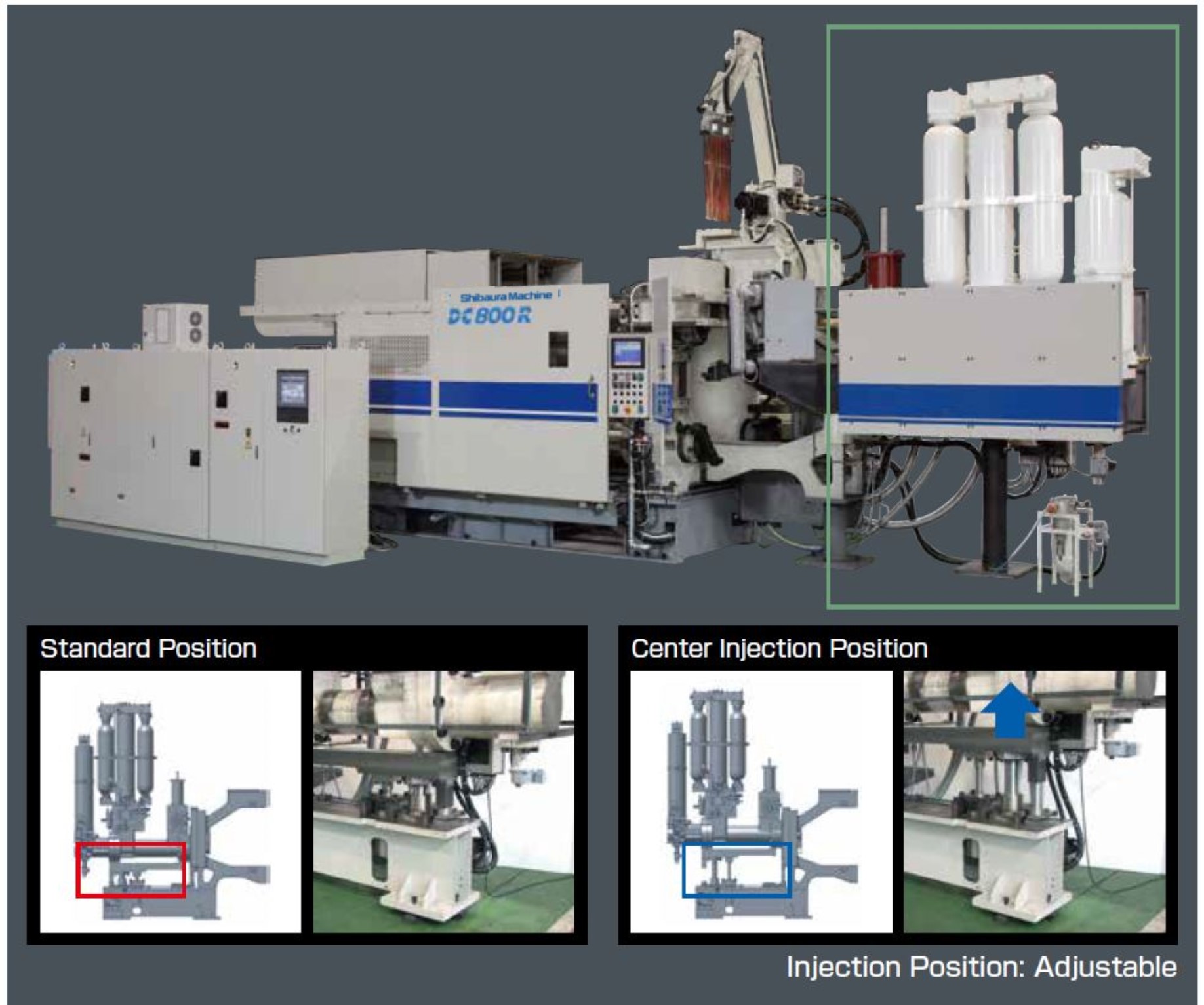

Multi Injection position system

The Multi Injection position system is available for various purposes:

Able to reduce flow distance to enhance die filling ability.

Easy to design your die with Multiple cavity.

Even small die can be run setting it on the center of platen.

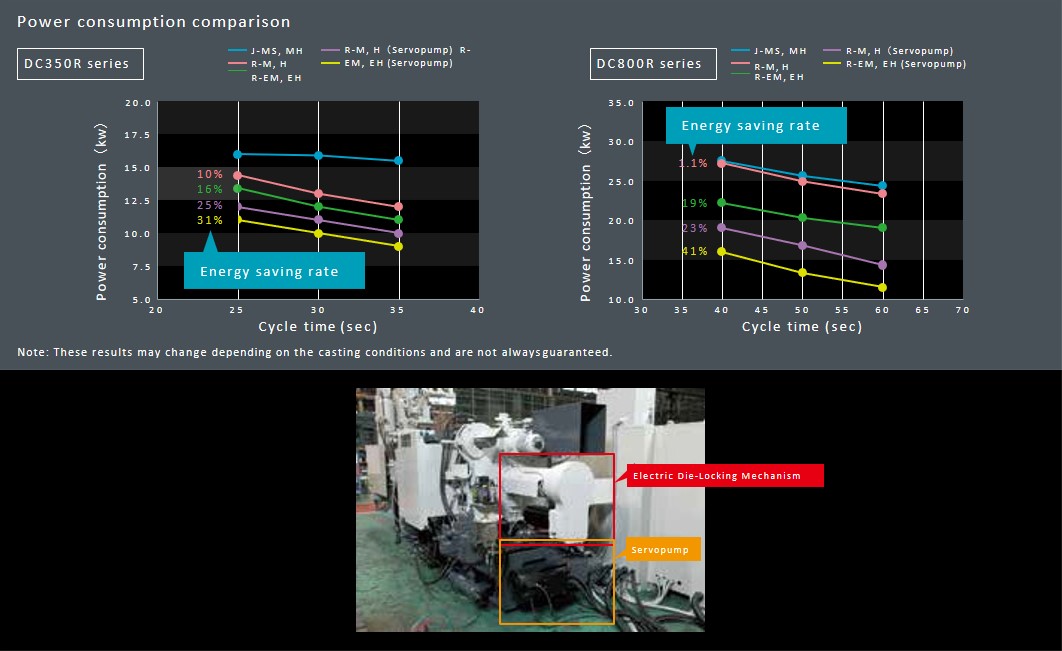

Improvement of Power Consumption

SHIBAURA MACHINE worked on the reduction of the power consumption, which is one of the measures for the environmental activities. Of the R-series, the R-E machine electric die locking system, the hybrid injection, the energy saving circuit, and the optional servo pump can be chosen according to the customer’s needs.

Squeeze Master(SQM-3)

Our Squeeze Master gives full control and high pressure to squeeze targeted location of die tooling of molten metal while solidifying to reduce porosity in a critical location.

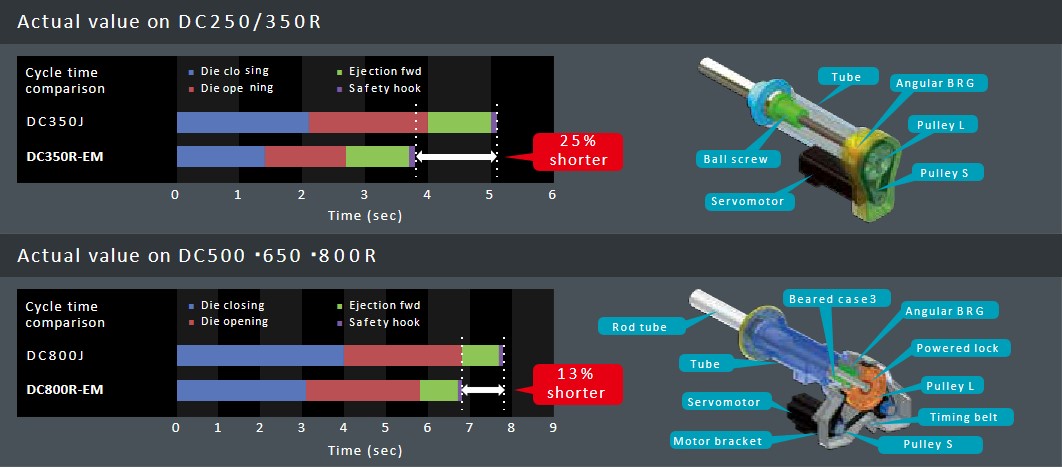

Electrical Die locking System R- E model machines

SHIBAURA MACHINE developed the electric die-locking system in 2000, the first in the industry.

Of the R-series, the R-E models have the electric die-locking system to achieve cycle time reduction, increase control, and help customers improve their productivity.

Specifications

0.17 mB