Precise Machining on the MP-(U) for Challenging Materials with the Grinding Attachment

ELK GROVE VILLAGE, IL, April 05, 2023 -

Multi-tasking machine tools have revolutionized the manufacturing industry, providing a versatile and efficient solution to various machining requirements. These machines are designed to perform several functions all in one setup.

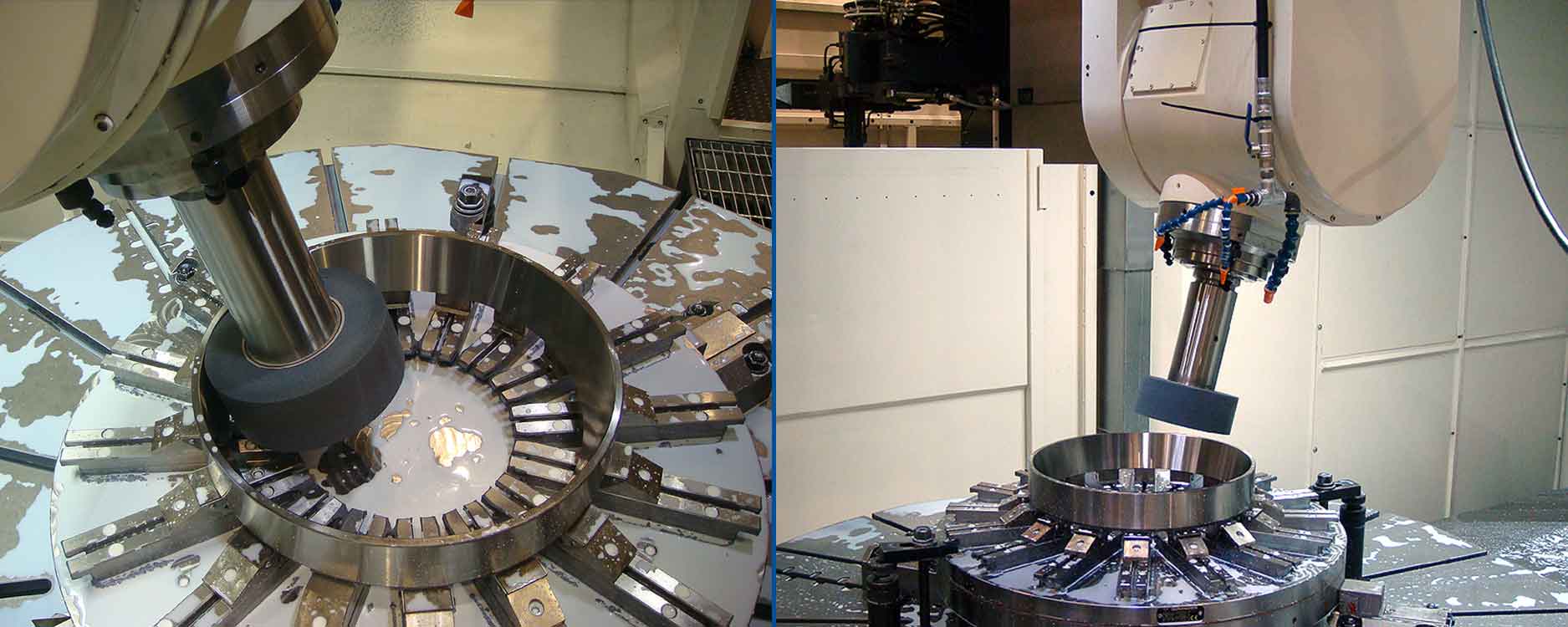

Shibaura Machine’s double column machining center MP-(U) series is a versatile multi-tasking machine that can be used for a variety of applications, including milling, drilling, and grinding. The grinding attachment is one of the key features of the MP-(U), allowing users to easily perform high-precision grinding operations, even with the most challenging materials.

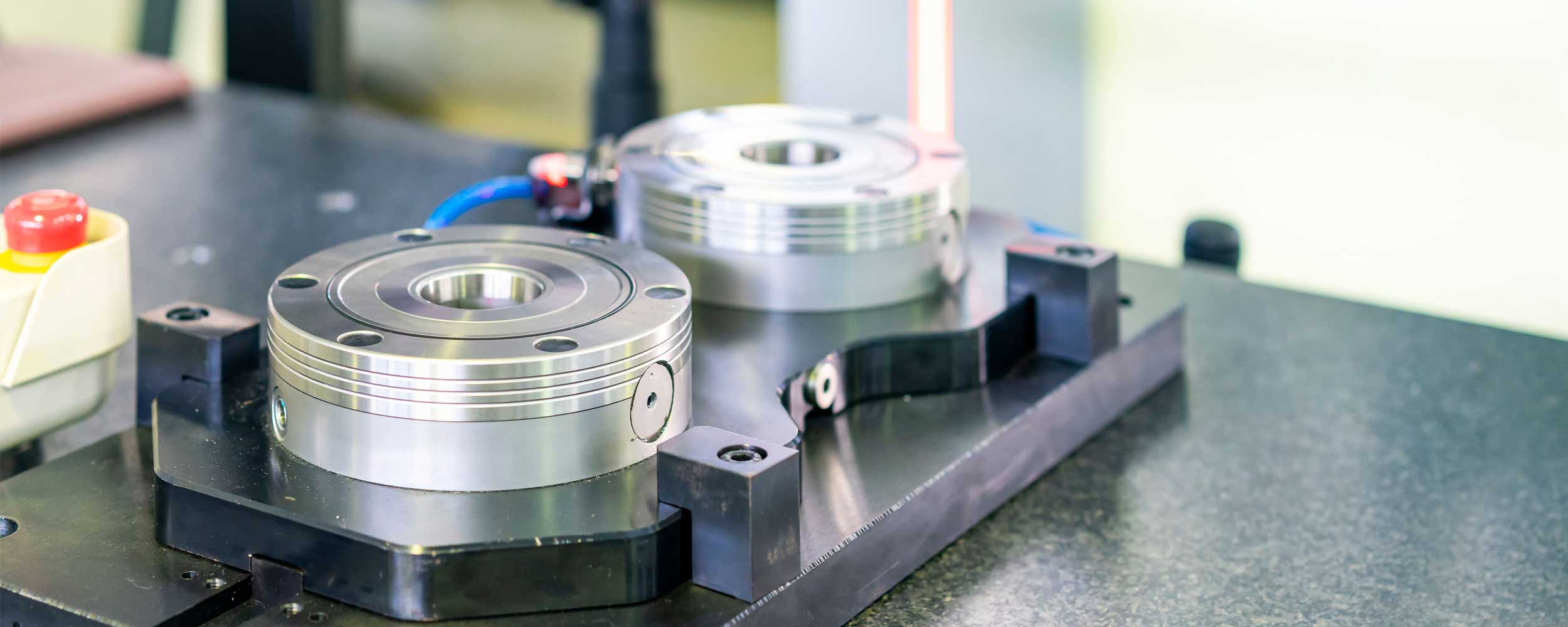

The grinding attachment on the MP-(U) is designed to be user friendly and highly precise. It consists of a grinding spindle, which is mounted on a special adapter that attaches to the machine's main spindle. The adapter is designed to be interchangeable, allowing machinists to quickly switch between different grinding applications.

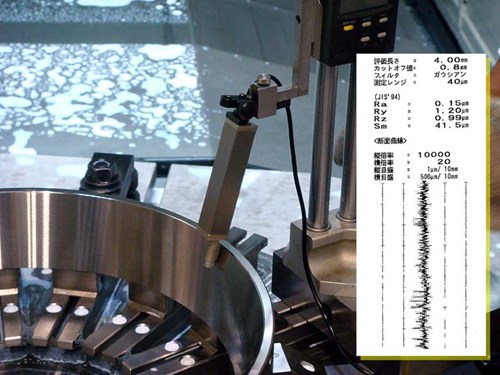

The grinding spindle is driven by a high-speed motor, which provides the power necessary to grind even the toughest materials. The spindle is also equipped with precision bearings and a dynamic balancing system, which ensures that it operates smoothly.

The grinding attachment on the MP-(U) is managed by the TOSNUC CNC control, which allows users to program the machine to perform a wide range of grinding operations. The TOSNUC includes a user-friendly interface that allows machinists to easily input the necessary parameters, such as the grinding speed, feed rate, and depth of cut.

Applications for Grinding

In addition to its precision and ease of use, the grinding attachment is highly versatile. It can be used for a variety of situations when a machining operation requires the removal of material from a workpiece with high precision and a fine surface finish.

Grinding cylindrical surfaces

Most commonly, the attachment can grind cylindrical surfaces, such as the outside diameter of a shaft or the inside diameter of a bore. When a high level of precision is required, such as in the manufacturing of automotive parts or precision components for machinery, this is a preferred method.

Grinding flat surfaces

Machinists can use the attachment to grind flat surfaces, such as the top of a workpiece or the surface of a block. Where a smooth and flat surface is required, such as in the manufacturing of precision components for machinery or aerospace parts this can be especially useful.

Machining Hard Materials With Precision

By adding a grinding attachment to the MP-(U), machinists can perform grinding operations on workpieces without the need for a separate grinding machine. This can help to reduce costs, increase productivity, and improve overall efficiency in manufacturing.

Contact the Machine Tool team and learn more about how the grinding attachment for the double column machining center MP-(U) series helps you achieve the precise results you need.

Related Articles View All Machine Tools Articles

Maximizing Horizontal Boring Machine Performance with TOSNUC and FANUC CNC Control Systems

ELK GROVE VILLAGE, IL, March 28, 2023 - Horizontal Boring Machines (HBM) have quickly become a critical component in the manufacturing process of various industries, and their precision and efficiency are vital for achieving high-quality results. One of th...

Read moreStart Improving Production With the Help of a Quick Change Workholding

ELK GROVE VILLAGE, IL, March 22, 2023 - In the world of manufacturing, time is money. Any downtime or delay in the production process can have a significant impact on a company's bottom line. This is where quick change workholding comes into play. Also kno...

Read moreMaximizing Efficiency in Machining with the Right Angle Head Attachment on your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 14, 2023 - As a machine tool operator, you know that there are many challenges involved in performing precision cutting, drilling, and other operations. Machining complex workpieces with multiple surfaces often require numerous...

Read moreBoost Your CNC Machining Confidence: On-Site Training Explained

ELK GROVE VILLAGE, IL, March 7, 2023 - As the manufacturing industry continues to grow and evolve, it's becoming increasingly important for companies to invest in their workforce through proper training programs.In the world of machine tools, on-site train...

Read moreMachine Tool Automation Options for Shibaura Machine's TMD Series

ELK GROVE VILLAGE, IL, February 28, 2023 - Efficiency and productivity are critical factors for success in today's fast-paced manufacturing industry. To maintain a competitive edge, manufacturers must continually seek new ways to optimize their processes a...

Read moreCritical Factors to Consider With Your Machine Tool Foundation

ELK GROVE VILLAGE, IL, February 15, 2023 - Machine tools are the backbone of the modern manufacturing industry and play a critical role in the production of goods and services. While the machine tools themselves are the main focus, their foundation is a cr...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools