Exploring The Benefits of On-Machine Measuring with Machine Tools

ELK GROVE VILLAGE, IL, September 9, 2022 -

Incorporating on-machine measurement on machine tools has increasingly become a way for shops to drastically reduce the time required to measure parts and reduce production lead time. As technology has evolved, it has also improved the quality of cutting work and reduced process waste, bringing shops a true competitive advantage.

Of course, this does not mean that 3D measurement is unnecessary but repeating machining and measurement while maintaining the same setup alleviates setup errors by humans and reduces errors in the machining process. On-machine measuring is an effective choice for low-volume, high-mix productions, and mass productions.

Drive Efficiency and Productivity in Your Production

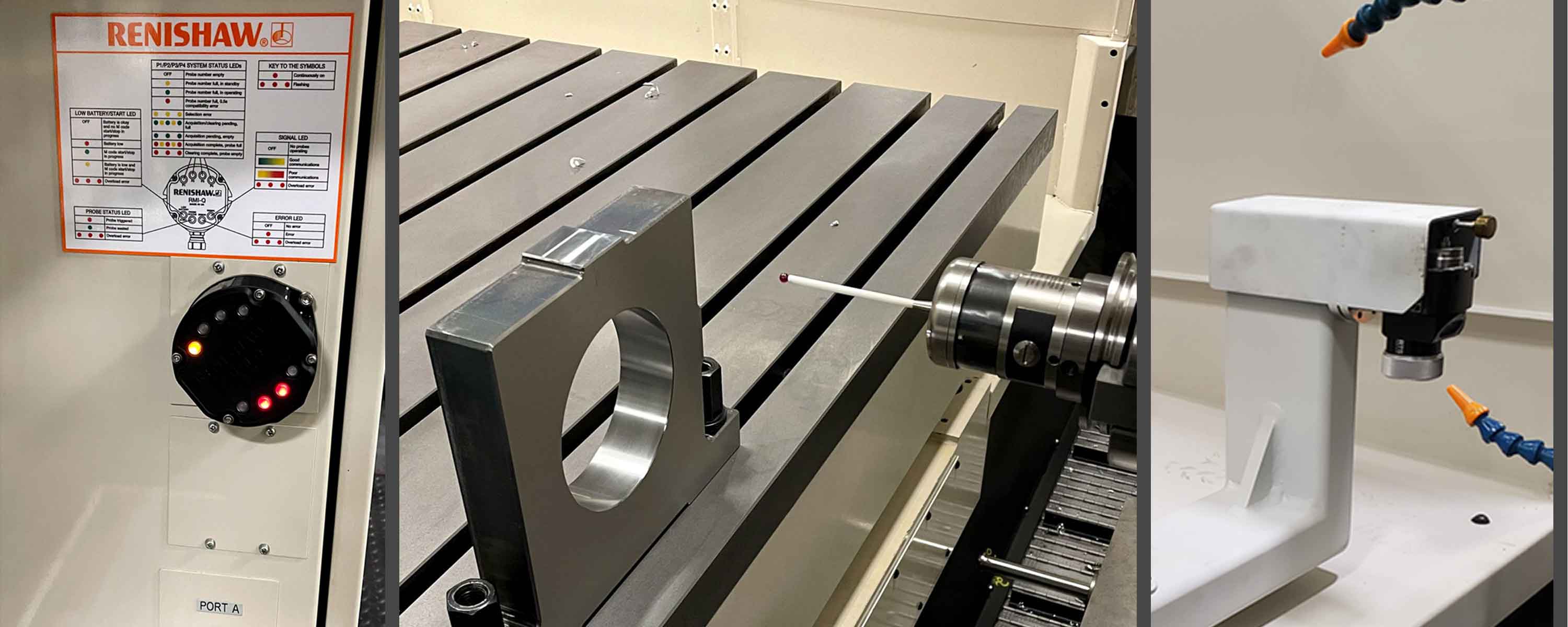

Measuring on the machine tool provides a valuable source of information in the machining process if done properly. Using its data allows for workpieces to be aligned before or in between the process, improve part quality, or even improve the overall production process. However, the time required for measurement directly affects the machine's operating rate so it is important to ensure machine tools' geometric accuracy to measure parts within all tolerances specified for the part, otherwise, the on-machine measurement will be unusable and the parts may not be machined to tolerance.

With the voice of the customer in mind, Shibaura Machine’s Automatic Measurement and Automatic Tool Length Measurement functions allow our customers the option to easily and reliably perform on-machine measurements. It is now possible to automatically create programs for measurement and then monitor and follow their progress to ensure part tolerances are maintained. This not only improves the machining accuracy of workpieces, but increases productivity, reduces machine stoppages, and provides valuable data to optimize the process.

Learn More

As shops continually work to improve quality and speed up productivity, on-machine measuring is a great function to consider. Our team recommends comparing the processing and measurement time while considering the size, shape, and machining cost of the workpiece in order to decide if on-machine measuring is the best option for your machine tools.

If your shop is looking to shorten work time and improve part quality, contact our Machine Tool Team to learn more about how the Automatic Measurement and Automatic Tool Length Measurement functions can help.

Related Articles View All Machine Tools Articles

See How machiNetCloud IIoT Solution is Improving Machine Tool OEE at IMTS 2022

ELK GROVE VILLAGE, IL, September 2, 2022 - As the Industrial Internet of Things (IIoT) continues to grow and evolve, shops can more accurately and easily create leaner operations. Shibaura Machine’s IIoT solution, machiNetCloud, will be on display and avai...

Read moreIMTS 2022 Special Financing Opportunity for the BTH-130.R24 Horizontal Boring Machine

ELK GROVE VILLAGE, IL, August 26, 2022 - With the International Manufacturing Technology Show (IMTS 2022) less than a month away (September 12-17 in Chicago), Shibaura Machine Company, America is gearing up to meet the attendees. Booth 339430 in the South ...

Read moreShibaura Machine Showcases the TUE-200(S) Extended Column and Ram Travel at IMTS 2022

ELK GROVE VILLAGE, IL, August 18, 2022 - The upcoming International Manufacturing and Technology Show will showcase the latest machining technologies and processes. Shops looking to streamline their CNC machining processes are invited to visit us at Booth ...

Read moreOptimize Your Shops Macro Programs to Boost Productivity

ELK GROVE VILLAGE, IL, August 18, 2022 - When talking about machine tool maintenance the first thing that comes to mind is often the mechanical aspects. From adjusting accuracy, changing oil and filters, and even cleaning the machine. With most machine too...

Read moreVisit Us at IMTS 2022 & See The FANUC Control on the BTH-130.R24 Horizontal Boring Machine

ELK GROVE VILLAGE, IL, August 2, 2022 - When it comes to carrying out the machining process, machinists want a control system that is both efficient and reliable in order to get the job done with high quality and consistency. In order to maintain high perf...

Read moreGlobal Aerospace Market Outlook for Manufacturers

ELK GROVE VILLAGE, IL, July 26, 2022 - As the aerospace industry continues to recover from the pandemic, companies will look toward leveraging digital solutions, increasing production, and expanding MRO activity. Trends in commercial air travel have shown ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools