Looking Beyond Standard Maintenance to Improve Machine Tool Life

ELK GROVE VILLAGE, IL, June 14, 2022 -

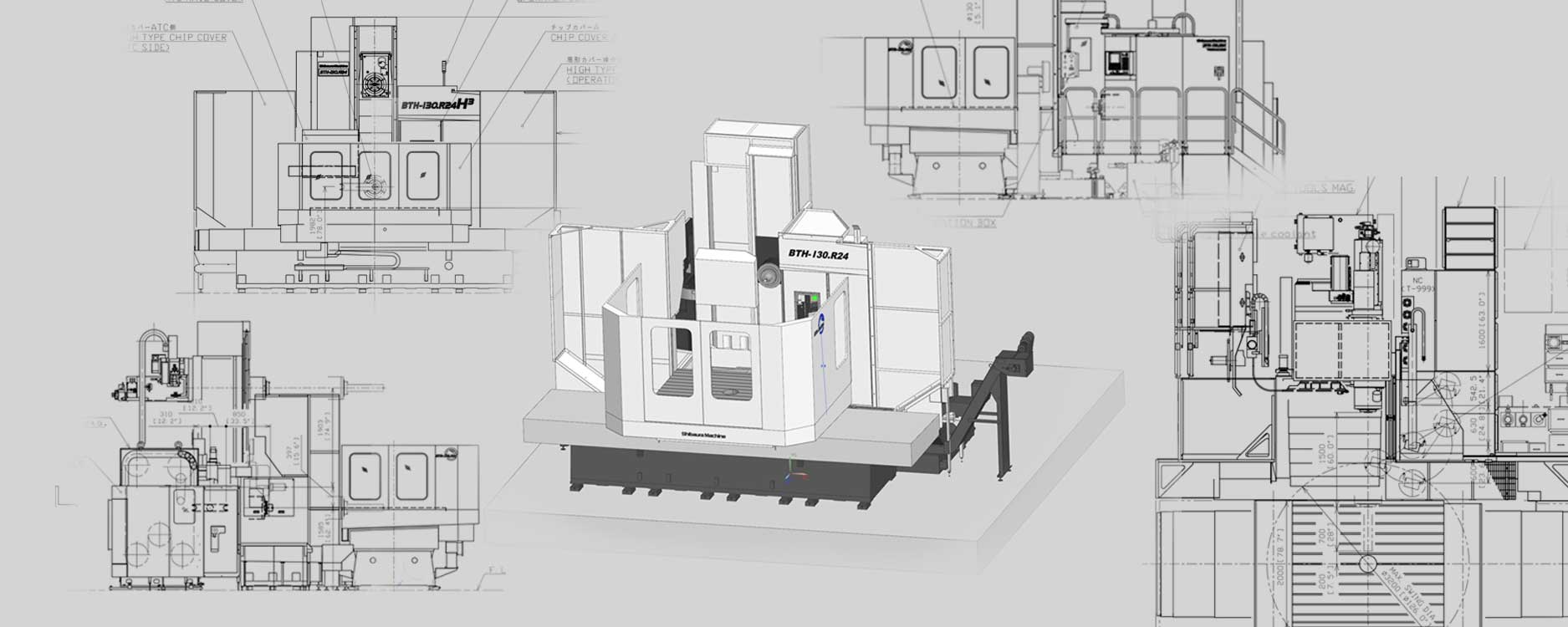

Your machine tool is a major investment and with that, you expect a long service life. While Shibaura Machine takes extensive measures to engineer world-class equipment, some still in use after 30+ years, it is also critical for machine owners to engage in maintenance to enable the machine tool to operate properly, produce quality parts, and continue running through the years.

Beyond standard maintenance, what else can owners do to ensure machine tool longevity?

Conditional monitoring is an increasingly popular option to get a clear picture of your machine tool’s health. Being able to aggregate accurate machine tool data 24/7 enables your team to make data-driven decisions when it comes to preventative maintenance. Specifically, vibration monitoring offers a simple way to strengthen your maintenance and machine tool reliability.

Prevent Issues Before They Arise

Being able to avoid unplanned downtime and improve machine tool operating performance starts with knowledge. Vibration sensors offer factories key insight into the wear of machine tool components, imbalances, and other changes early on. Plant personnel can then analyze the vibration data and make decisions to enable early problem diagnosis and prioritize maintenance efforts.

This type of data acquisition has been reported to:

- Improve downtime response

- Move teams away from reactive maintenance

- Save costs on prematurely changing machine parts

Start Improving Uptime

The addition of vibration sensors is just one way to understand your machine tool’s health and provide early identification of issues. This can not only extend the life of the machine tool but further enhance its operational benefits.

Contact the Machine Tools team to learn more about improving the life of your machine tool.

Related Articles View All Machine Tools Articles

Simplifying Machine Tool Importation For Our North American Customers

ELK GROVE VILLAGE, IL, June 6, 2022 - Shopping for the right machine tool can be complex.From choosing a machine tool to meet production and budgetary requirements to ensuring importation procedures are met and machinery is compliant with North American re...

Read moreHow We’re Helping You Create a World Class Manufacturing Facility

ELK GROVE VILLAGE, IL, May 31, 2022 - Is it worth the time to review and put together a facility layout? The answer is a resounding yes. From being able to speed up your process, improve productivity, and even maximize square footage your facility layout c...

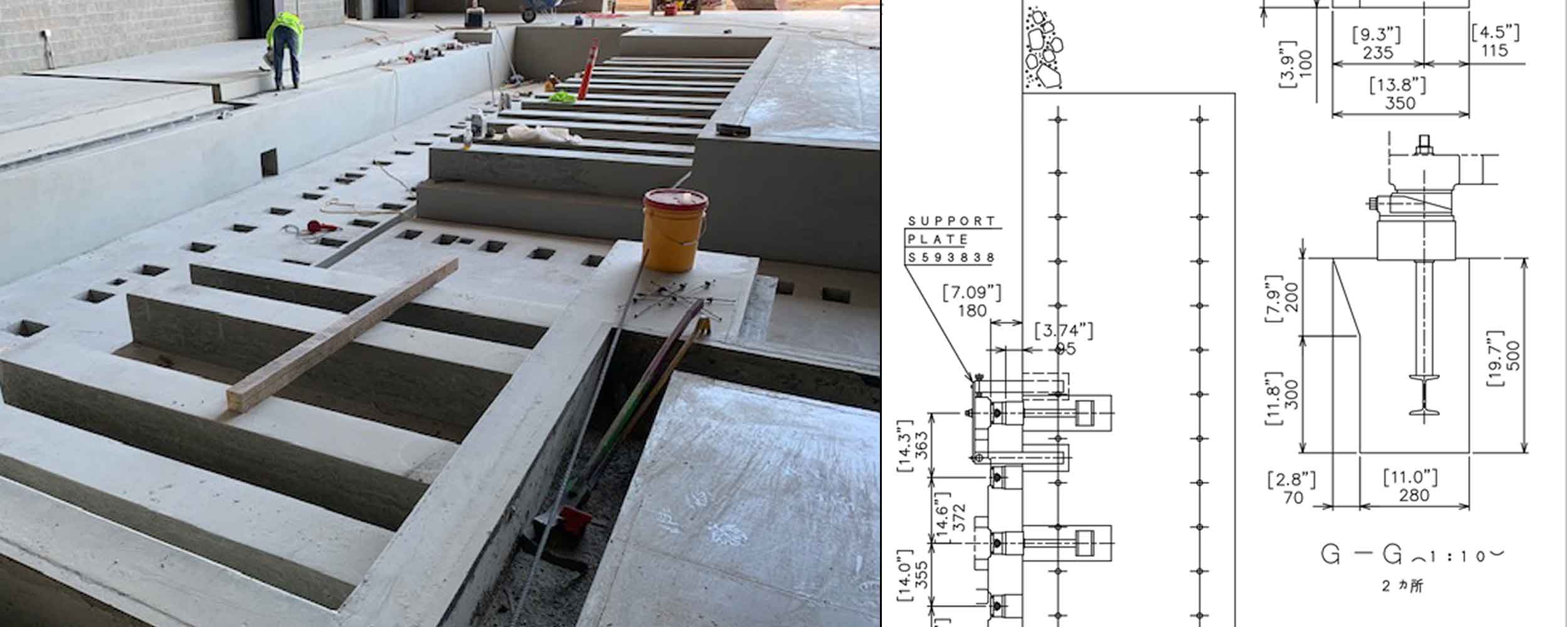

Read moreUnderstanding the Importance of Foundations for Precision Machine Tools

ELK GROVE VILLAGE, IL, May 23, 2022 - Would a contractor ever build a house without a solid foundation? The answer is a resounding no. Without a solid foundation not only will the home be unstable, but will likely bring in unwanted outside elements. The sa...

Read moreConsider High-Pressure Coolant to Improve Chip Management

ELK GROVE VILLAGE, IL, May 16, 2022 - Managing machine tool cutting variables such as feeds, speeds and depth of cut play a key role in eliminating unpredictable cutting tool wear and poor chip management. Incorporating a high pressure coolant system will ...

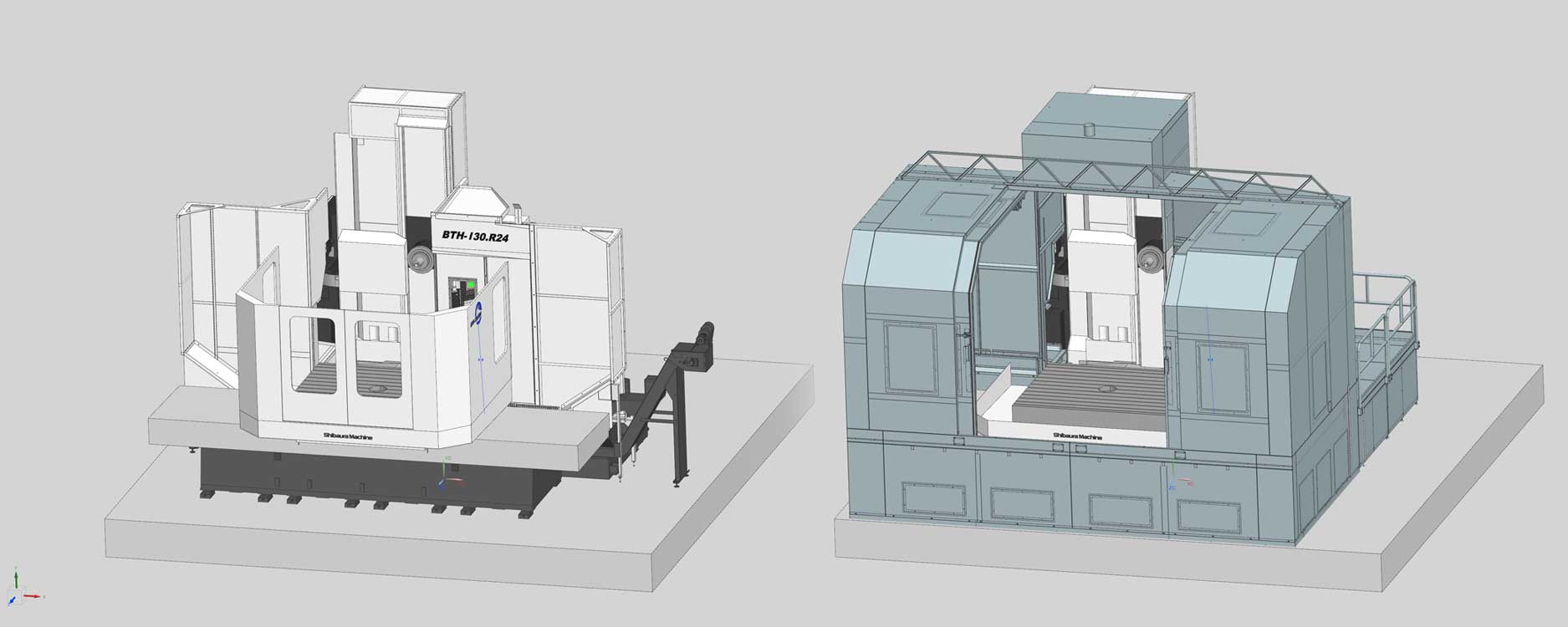

Read moreUnderstanding the Design Principals of Machine Enclosures

ELK GROVE VILLAGE, IL, May 9, 2022 - Machine enclosures have quickly become mainstream as a way to ensure your machine is operating as efficiently as possible and improve your work zone environment. The enclosure not only contains chip and coolant but dete...

Read moreThe Future of Machining in the EV Market

ELK GROVE VILLAGE, IL, May 2, 2022 - The Electric Vehicle (EV) market continues to shake up the entire supply chain of the automotive industry with its unprecedented growth rates. Between 2020 and 2026, the size of the global EV market is expected to incre...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools