How Mold Movement During Charging Can Reduce Cycle Times in Injection Molding

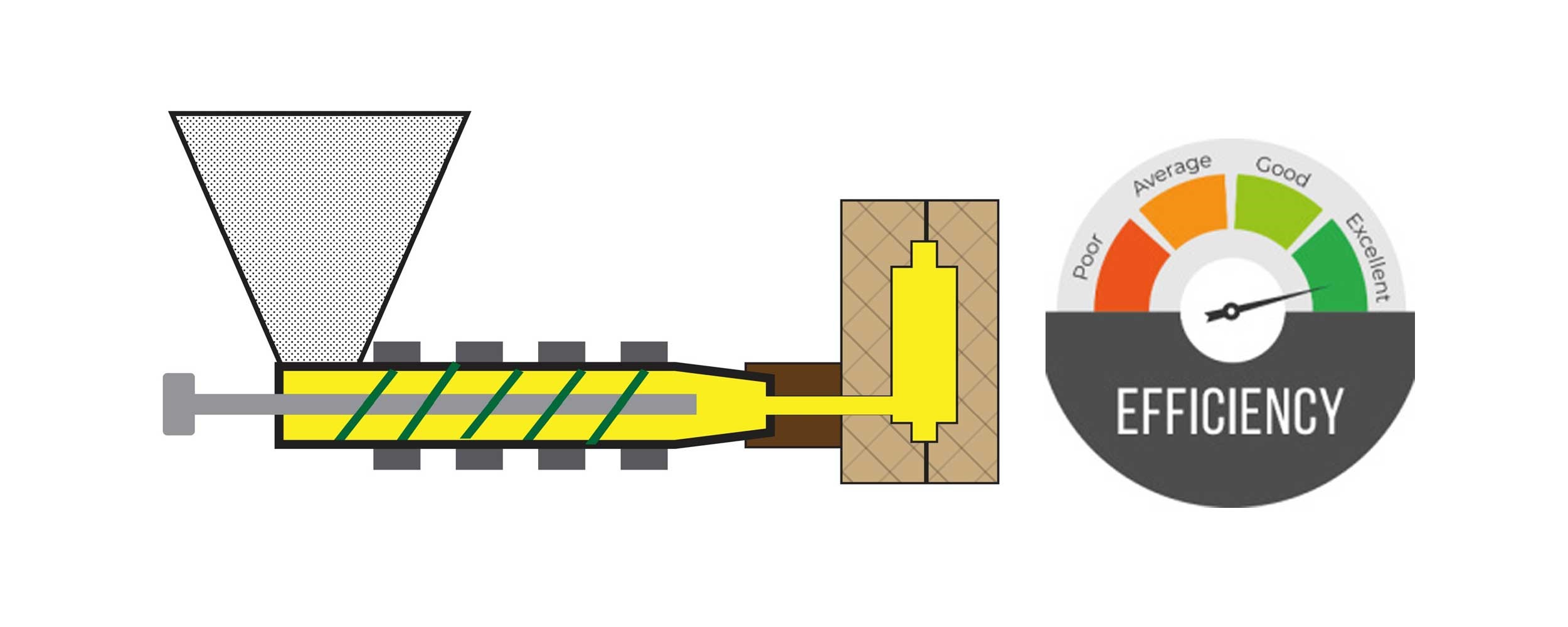

ELK GROVE VILLAGE, IL, November 7, 2023 - As the injection molding industry continues to grow at a rapid pace, efficiency is paramount. The capability of simultaneously charging during mold movement has become a game-changing innovation, setting new standards for cycle times, energy savings, and product quality.

Traditional Methods: Sequential Operations

Traditionally, screw charging and mold movement were executed separately and sequentially in hydraulic injection molding machines. This meant that the mold movement would not begin until the screw charging process was completed. Since the machine couldn't move on to the next step until the previous one was finished this creates increased cycle times.

The Modern Approach: Simultaneous Operations

Using all-electric machines like the Shibaura Machine SXIII all-electric series, screw charging and clamping can be performed simultaneously. By overlapping these processes, the machine can produce parts faster, increasing throughput. This can offer a significant advantage in high-volume production settings.

The Shibaura Machine All-Electric Advantage

By allowing simultaneous screw charging and mold movement, the SXIII series takes efficiency to a whole new level. With independent servo motor control of each axis, screw charging can be done during mold movement, reducing cycle time and increasing efficiency.

The SXIII series of all-electric injection molding machines are not just fast; they're smart. By allowing simultaneous screw charging and mold movement, these machines set a new standard in efficiency and quality.

Contact the Injection Molding team to learn more.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

The Rise of All Electric LSR Injection Molding Machines

ELK GROVE VILLAGE, IL, September 29, 2023 - Are you looking for a way to produce high-quality, intricate silicone components at unprecedented speeds? You're not alone. In a manufacturing landscape where efficiency, versatility, and precision are pivotal, t...

Read moreImprove Your Injection Molding Process with Barrel Temperature Shift Mode

ELK GROVE VILLAGE, IL, August 23, 2023 - To ensure optimal product quality, consistency, and operational efficiency, precise temperature control plays a critical role in the injection molding process. One essential feature that can significantly impact inj...

Read moreMastering Material Changeovers in Injection Molding

ELK GROVE VILLAGE, IL, August 8, 2023 - Optimizing efficiency and minimizing costs are crucial to success in the fast-paced world of injection molding. However, one aspect that often poses difficulties for molders is the purging process. The traditional me...

Read morePartnering for Success: Shibaura Machine's Technical Sales Support Services

ELK GROVE VILLAGE, IL, July 20, 2023 - As the manufacturing landscape continues to evolve, having a reliable technical sales support team becomes increasingly important. With inefficiencies in injection molding processes translating into financial losses, ...

Read moreInvest in Your Success: Shibaura Machine's Training Programs for Injection Molding Professionals

ELK GROVE VILLAGE, IL, July 5, 2023 - When it comes to injection molding, having a well-trained team is crucial for maximizing machine performance and achieving optimal results. Training ensures that all personnel understand not only the machine's capabili...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools