Does Your Injection Molding Machine Offer Easy Visibility into Diagnostics and History?

ELK GROVE VILLAGE, IL, February 23, 2021 – Troubleshooting and maintenance can become tedious and time-consuming tasks on the manufacturing floor. What would it mean to your business if you were able to more efficiently understand your machine and have quick visibility into the history of its operations? Probably improved uptime, employees being able to focus on other revenue-generating operations, and increased overall efficiency could be achieved.

In the development of the V70 controller for our injection molding machines, Shibaura Machine’s focus was on an intuitive design that allowed for ease of use. That meant when developing the experience around the diagnostic and history functions we wanted the screens to be clearly arranged, convenient, and without a time-consuming learning curve. We believe that putting all the machine’s movements in the palm of the user’s hand is key to being able to improve overall efficiency.

Clean Design Creates Easy Visibility into Diagnostics & History

The V70 controller offers highly-efficient navigation that many compare to their smartphone. The design of the diagnostic and history screens takes into account a typical user journey of the controller which allowed us to develop a fast and simple-to-understand interface.

Several highlights to the diagnostic and history screens include:

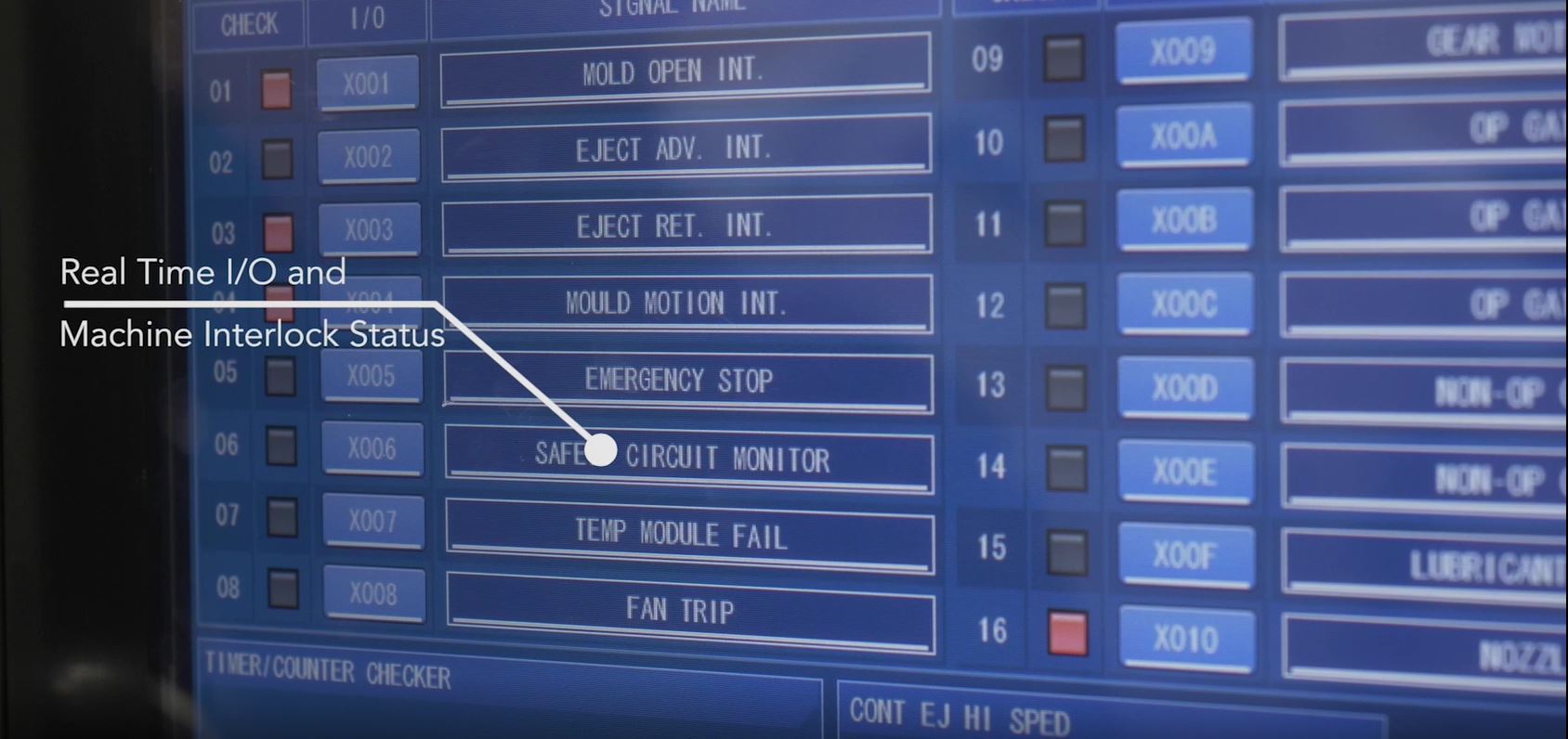

I/O Checker

The checker screen shows all machine inputs and outputs, each of which is labeled with a description for easy troubleshooting.

Ladder Logic Display

The ladder logic display allows the user to view the entire machine sequence in real-time.

Machine Interlock Screen

This page shows all of the machine interlocks, color-coded by section of the machine and the current status of each. There is also a section showing the robot interlock and other integrated auxiliaries in detail with the current status.

History Screens

Tabs are clearly displayed on the V70 controller for the user to access the Set History, Alarm History, Stop History, and Operation History screens.

- Set History - Used in conjunction with the user log-in feature, the user can see the last 1,000 changes made - the old setting, the new setting, and who made the change.

- Alarm History - View the last 1,000 machine alarms

- Stop History - View the last 1,000 times the machine stopped, and why.

- Operation History - View the last 1,000 changes to the machine operation mode.

In addition, whenever a machine setting is touched, the setting window shows the last 7 changes made to this setting so you can quickly view changes that have affected recent operations.

The Shibaura V70 controller was designed with the user in mind through and through. Learn more about all the features that allow for a more efficient manufacturing operation by contacting our team of experts today.

Contact us today to learn how the diagnostic and history features of our V70 controller can benefit your operation!

Related Articles View All Articles

Why Injection Molding Machine Design Matters - And What to Look For

ELK GROVE VILLAGE, IL, February 19, 2021 – When you have a well-designed injection molding machine there are no limits to what types of molded parts you can create. Whether it's automotive, packaging, medical, or custom plastics - an injection molding mach...

Read moreMinimizing Injection Molding Complexity without Compromising Capability

ELK GROVE VILLAGE, IL, February 10, 2021 – The convenience of your injection molding machine controller correlates directly with your factory production efficiency. A controller that is not only powerful but offers intuitive operation, simple navigation, ...

Read moreAll-Electric Injection Molding Machines Offer More Than Energy Savings

ELK GROVE VILLAGE, IL, February 3, 2021 – Did you know energy spending in most injection molding plants is one of the highest costs month after month? At the end of the day, it is often costing more to run old machines then it would to invest in new, energ...

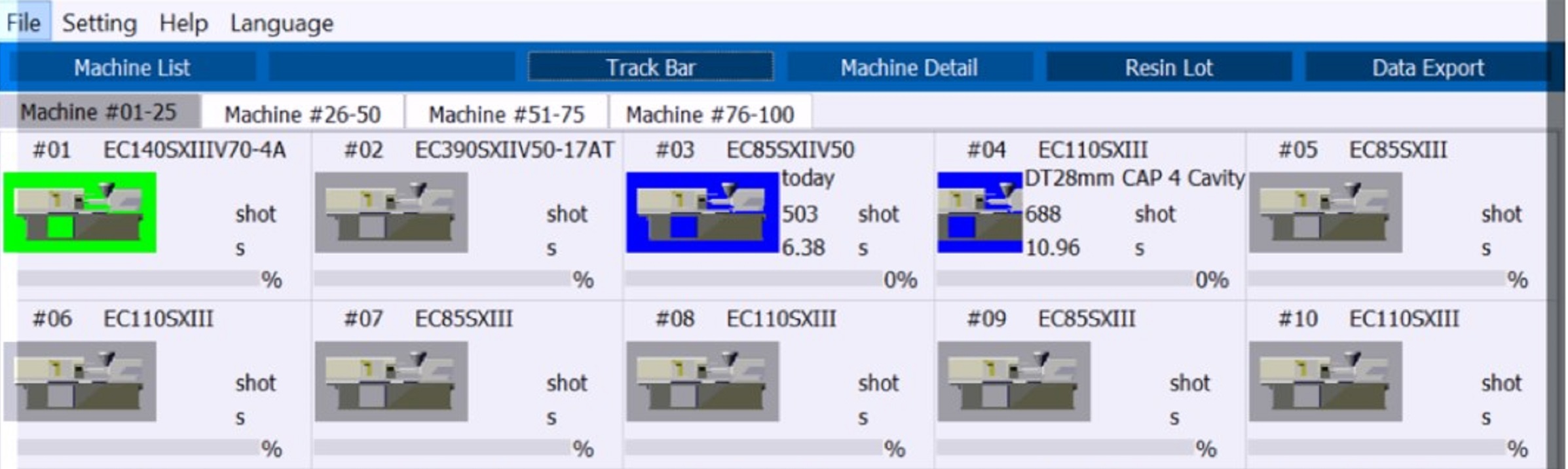

Read moreImprove Quality Control and Productivity with the iPAQET Remote Data Management System

ELK GROVE VILLAGE, IL, January 27, 2021 – Not all monitoring and data management systems are created equal. Many systems are prone to errors, have less than easy to use interfaces, or require someone to be in front of the machine- oftentimes collecting dat...

Read moreHow to Minimize Injection Molding Machine Downtime

ELK GROVE VILLAGE, IL, January 19, 2021 – Whether planned or unplanned, machine downtime is very costly. Aside from directly impacting production and labor, machine downtime extends to other areas of operation and can affect the organization as a whole. An...

Read moreReducing Reject Rates for Injection Molding is Within Reach

ELK GROVE VILLAGE, IL, January 13, 2021 – If parts are considered defective they are likely getting rejected by customers. That means the cost lands on you, but with a premium because you have equipment and labor costs tied into it. Luckily, the right inje...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools