Servo Motorized Moving Platens for Intelligent Die Casting

ELK GROVE VILLAGE, IL, January 9 2025

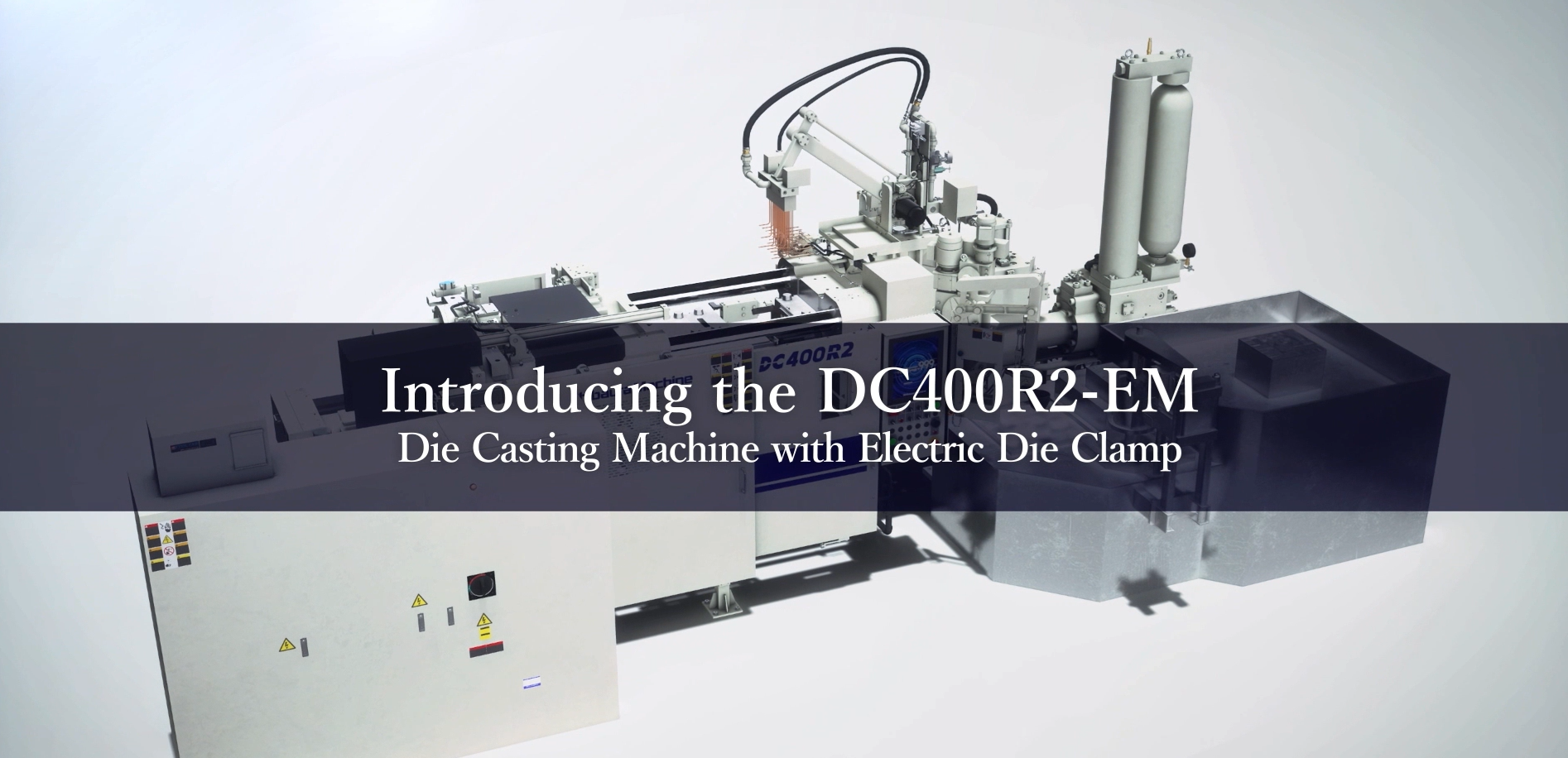

With advancing Technology, Productivity, and Sustainability top of mind, the Shibaura Machine Company, America die casting team is excited to announce our NEW High-Pressure High-Speed Die Casting Machines.

Featuring an Electric Servo Toggle Clamping Die Closing Linkage system provides true locking force, these machines are engineered for increased productivity, uptime, and effectiveness while reducing environmental impact—a win for manufacturers and the planet alike.

In die casting, every second counts. From automotive components to consumer parts, the pressure to meet production goals while maintaining quality is constant.

With over 75 years of experience in manufacturing innovation and more than 50 years of expertise in servo motor technology, Shibaura Machine continues to set the standard for efficiency and precision with its innovative servo motorized moving platen system, designed to complement the precision of its toggle clamping technology.

Unlike traditional hydraulic systems that rely on fixed travel distance and frequent maintenance, the Shibaura Machine servo motorized moving platen introduces programmable positioning, precision, reduced maintenance, and cycle time improvements. For manufacturers seeking to stay competitive in a fast-paced industry, this system offers a smarter, cleaner, and more productive solution.

Redefining Cycle Times

In high-volume die-casting every second of the production cycle counts toward meeting tight deadlines. With a servo motorized moving platen, you can reduce cycle times, improving efficiency and throughput. While the time saved per cycle may seem minimal, consider the cumulative effect:

- Increased Output: Over a single shift, the reduced cycle times allow you to produce more parts without adding extra hours or resources.

- Long-Term Productivity Gains: Across months of production, these incremental time savings contribute to significant increases in overall productivity and profitability.

This improvement is especially impactful in larger machines, where longer travel distances mean that even greater reductions in cycle time can lead to substantial gains. By optimizing each movement, the Shibaura Machine servo motorized moving platen helps you get the most out of your equipment, ensuring that every second is utilized effectively.

Programmable Precision: Smarter Platen Movement

The Shibaura Machine servo motorized moving platen offers programmable movement, enabling the programmable platen position to open and close only as far as needed for the part extraction and die spray. This saves both time and energy, while also reducing wear on the machine.

Casting components of varying sizes, with the programmable system, you can:

- Optimize Cycle Time: The electric toggle die-clamping mechanism delivers exceptional productivity compared to conventional hydraulic systems. This is achieved through faster mold opening and closing, as well as the ability to perform overlapping operations with other processes.

- Enhanced Process Efficiency: The electric toggle system enables simultaneous operations that were traditionally performed sequentially in hydraulic systems. Tasks like core retracting, part extraction, die spray, and ladling can now occur concurrently, significantly improving efficiency.

- Save Floor Space: The innovative Space-Saving Design of the die-clamping toggle on larger tonnage machines reduces the overall footprint, offering significant space savings compared to traditional hydraulic machines.

- Reduced Maintenance: The electric mechanism minimizes the risk of hydraulic fluid leakage, cutting down maintenance requirements. Additionally, the machines are equipped with the advanced TOSCAST controller, ensuring ease of maintenance and reliable operation.

Cleaner, Lower-Maintenance Operations

The Shibaura Machine servo motorized moving platen replaces the hydraulic cylinder with an advanced electric servo drive system, offering several key advantages:

- Reduces cycle time improving productivity.

- Reduces maintenance needs, saving time and labor costs, and reducing unplanned downtime.

- Offers a cleaner, more environmentally friendly operation with no risk of hydraulic fluid spills.

- Eliminates common hydraulic challenges, such as seal failures, heat generation, and fluid management.

For a manufacturer running high-volume operations, the faster platen movement, reduced unplanned downtime, and maintenance savings mean more focus on production and less on troubleshooting.

Designed for the Future of Manufacturing

As manufacturers look to 2025 and beyond, innovation in die casting will play a critical role in staying competitive. Shibaura Machine’s servo motorized moving platen offers a pathway to smarter, more efficient production.

Ready to transform your die casting operations? Contact the Shibaura Machine Die Casting team to explore how the servo motorized moving platen can work for you.

Shibaura Machine Company, America, is a premier provider of advanced manufacturing solutions. With a strong commitment to innovation, quality, and sustainability, we deliver products that not only meet but exceed customer expectations.

Learn more about Shibaura Machine Company, America and the future of die casting contact our Die Casting Team.

- Phone: 888-593-1616

- Email: dc-sales@shibaura-machine.com

Achieving manufacturing excellence has never been easier.

Want to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools