Toggle Clamping Linkage Systems in Die Casting Machines

ELK GROVE VILLAGE, IL, December 12, 2024

In high-pressure die casting, achieving stability and precision during each cycle is critical. Even small inconsistencies—like mold separation or uneven pressure—can lead to defects, increased post-processing, and costly unplanned downtime. To combat these challenges, a robust toggle clamping linkage system becomes essential for maintaining secure mold closure, distributing pressure uniformly, and adapting to various casting needs.

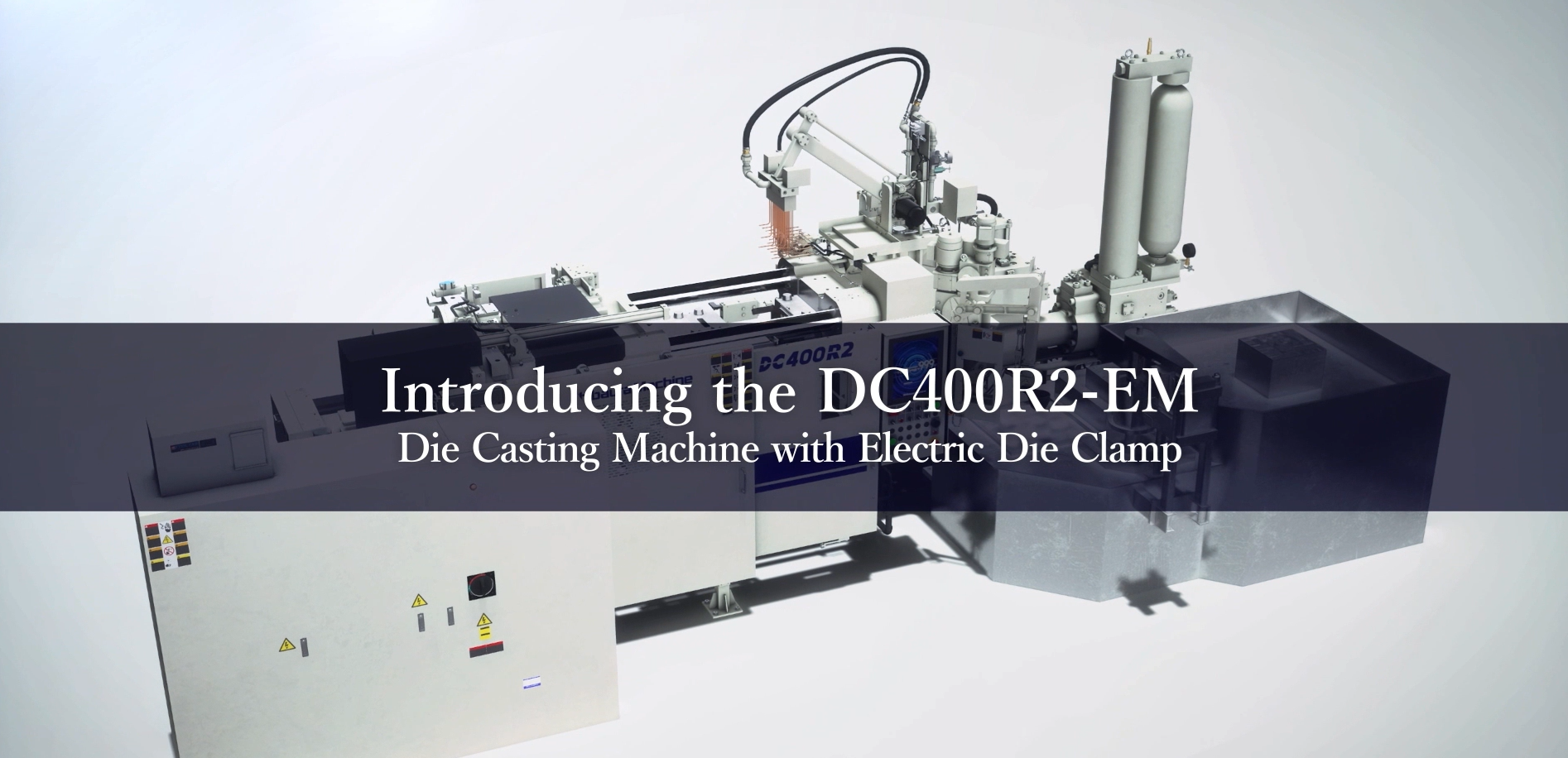

Shibaura Machine’s double multiple shear toggle clamping linkage system not only improves casting quality but also supports efficient, reliable production. With a focus on stability and durability, this system is built to help manufacturers overcome common casting issues while maintaining consistent quality and minimizing downtime.

The Role of Double Multiple Shear Toggle Clamping Systems

In die casting, the toggle clamping linkage system plays a crucial role in holding the mold tightly closed during casting, resisting the internal pressure of molten material. While low-pressure casting may only require a simple heavy plate for mold closure, high-pressure casting demands a more sophisticated solution. A system without toggles or a two-platen design lacking linkage can result in mold separation, flash, or other defects, jeopardizing production quality and efficiency.

The double multiple shear toggle clamping linkage system enhances durability and precision by incorporating multiple toggle mechanisms and shear points. This proven system provides superior clamping force, stability, and consistency, meeting the rigorous demands of high-pressure die casting.

Key Functions of a Toggle Clamping Linkage System

The double multiple shear toggle linkage system performs three critical actions in every casting cycle:

- Closing the Mold: The toggle linkage securely close the mold, locking it firmly to withstand high injection pressures. This ensures stability and precision during the casting process.

- Applying Clamping Force: The linkage extends to distribute uniform clamping force across the die, preventing mold separation and ensuring defect-free parts.

- Opening the Mold: After casting, the system retracts smoothly, enabling efficient part ejection and minimizing cycle times for steady production.

This time-tested system ensures stability throughout the casting process, addressing key challenges and delivering consistently high-quality results.

A double multiple shear toggle clamping linkage system design offers several important benefits that address common challenges in high-performance die casting:

- High Clamping Force: The linkage design steel pins in steel bushings maximizes clamping force, securely holding the mold closed against high-pressure injection, ensuring durability over extended production runs.

- Reduced Wear and Maintenance: The double multiple shear design distributes force evenly, minimizing stress on individual components and reducing downtime.

- Versatility Across Applications: This system adapts to various alloys, materials, and part geometries, making it ideal for diverse industries such as automotive, electronics, and healthcare.

Addressing Key Challenges in Die Casting

Inconsistent mold closure, dimensional inaccuracies, and material limitations are common pain points in die casting. A toggle-free system or a two-platen design without linkage can exacerbate these issues, leading to higher rates of defects and post-processing requirements. The time-tested double multiple shear toggle clamping system counteracts these risks by ensuring uniform pressure and secure mold closure.

This system also enhances machine longevity. By reducing mechanical wear and distributing force evenly, manufacturers experience fewer interruptions and longer production cycles without degradation in performance. This durability is especially critical in high-pressure environments where precision is non-negotiable.

The versatility of Shibaura’s linkage system also provides a significant advantage, especially for manufacturers working with various alloys and components across industries. Whether in automotive, electronics, or healthcare applications, Shibaura’s system supports a range of materials and casting requirements, adapting easily to different production needs. This flexibility allows manufacturers to meet diverse client demands without investing in separate systems for each application, reducing overall costs and simplifying operations.

Building a Future-Ready Foundation for Reliable Die Casting

Looking ahead, Shibaura Machine’s commitment to innovation ensures its linkage systems remain adaptable to the future demands of modern manufacturing. Shibaura’s linkage systems will evolve, offering manufacturers the tools they need to optimize productivity and respond to new challenges effectively.

By addressing the fundamental challenges of high-pressure die casting and providing a reliable, adaptable solution, the double multiple shear toggle clamping linkage system lays the foundation for long-term success in a demanding industry.

About Shibaura Machine Company, America

Shibaura Machine Company, America, is a premier provider of advanced manufacturing solutions. With a strong commitment to innovation, quality, and sustainability, we deliver products that not only meet but exceed customer expectations.

Learn more about Shibaura Machine Company, America and the future of die casting contact our Die Casting Team.

- Phone: (888) 593-1616

- Email: dc-sales@shibaura-machine.com

Achieving manufacturing excellence has never been easier.

Want to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools