Incorporating Environmental Awareness in Die Casting Operations

ELK GROVE VILLAGE, IL, November, 14 2024

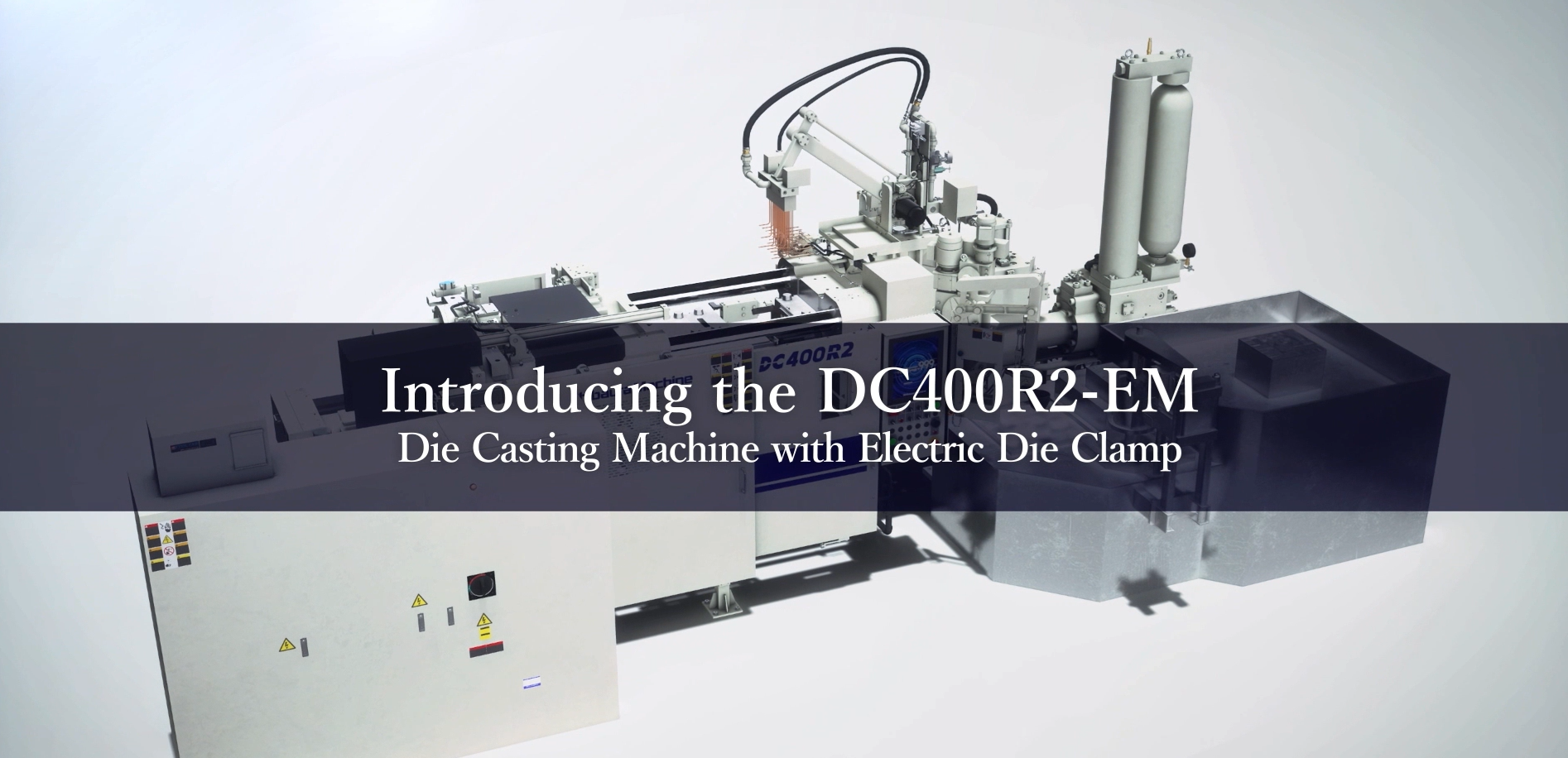

With sustainability top of mind, Shibaura Machine Company, America is excited to showcase the DC400R2-EM High-Pressure Die Casting Machine. Featuring an Electric Servo Toggle Die Closing system, 4,000 kN of mold locking force,and electric servo technology on the hydraulic pump, this machine is engineered for increased productivity, uptime, and effectiveness while reducing environmental impact—a win for manufacturers and the planet alike.

1. Save Cycle Time

With Shibaura Machine’s DC400R2-EM, speed meets precision. The electric servo toggle die-closing system isn’t just designed for faster movement—it’s engineered for smarter operation. This system provides precise platen positioning and control over each stage of the die-casting cycle, reducing cycle times, enhancing machine utilization , and boosting productivity, ultimately improving overall equipment effectiveness (OEE).

In high-volume manufacturing, shaving off even a few seconds can lead to a big boost in output. By reducing cycle time without sacrificing consistency, Shibaura Machine makes it easier to keep pace with demand while maintaining the highest quality standards.

2. Save Energy

Sustainability is at the heart of the DC400R2-EM’s design. By utilizing electric servo technology instead of an AC motor on the hydraulic pump, this solution optimizes energy use during operation, delivering power and speed precisely when needed. The result is lower energy consumption and a substantial reduction in CO2 emissions.

For manufacturers, this dedication to energy efficiency translates to reduced operational costs and a smaller environmental footprint—a win-win for productivity and sustainable practices

3. Save Maintenance

Maintenance can be a major source of downtime and expense, but the DC400R2-EM is designed to minimize these challenges. The shift from traditional hydraulic motors, PQ valves, and cylinders to electric servo technology reduces the risk of hydraulic issues and the associated maintenance required.

This means less time spent on downtime and more time focusing on productivity . Plus, fewer leaks and spills contribute to a cleaner, safer work environment.

Designed with Operators in Mind

Beyond its core functions, the DC400R2-EM is designed with operators in mind. Equipped with Shibaura Machines’s intuitive TOSCAST control system, the machine offers a user-friendly interface that allows operators to easily program, monitor, and adjust casting parameters as needed.

This flexibility is essential in fast-paced production environments, where the ability to make quick adjustments can optimize efficiency and ensure consistency.

Integrated IIoT Connectivity with machiNetCloud

The DC400R2-EM also integrates seamlessly with Shibaura’s machiNetCloud platform, bringing connectivity and intelligence to the forefront of die casting. With machiNetCloud, managers have access to real-time data on machine performance, allowing them to monitor, analyze, and respond to any changes necessary .

This IIoT capability is looking in the future to support predictive maintenance, helping operators anticipate and address potential issues before they impact production—a smart solution for minimizing downtime and maximizing productivity.

About Shibaura Machine Company, America

Shibaura Machine Company, America, is a premier provider of advanced manufacturing solutions. With a strong commitment to innovation, quality, and sustainability, we deliver products that not only meet but exceed customer expectations.

Learn more about Shibaura Machine Company, America and the future of die casting contact our Die Casting Team.

- Phone: (888) 593-1616

- Email: dc-sales@shibaura-machine.com

Achieving manufacturing excellence has never been easier.

Want to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools