Weight Savings in Automotive Design Through Die Casting: Enhancing Efficiency with Shibaura Machine

ELK GROVE VILLAGE, IL, July 25, 2024

In the competitive landscape of automotive design, optimizing weight reduction is paramount. Lowering vehicle weight enhances fuel efficiency, boosts performance, and reduces emissions, making it a critical goal for manufacturers.

One of the most effective ways to achieve significant weight savings is through the use of die castings. This article will explore how die casting can be used to achieve weight savings in automotive components, the material advantages it offers, and how these techniques can be applied across various parts of a vehicle.

A New Perspective in Die Casting Complexity

Die casting is often lauded for its ability to produce complex, near-net-shape components. But what does this mean in practical terms? Essentially, die casting enables the creation of intricate parts that require minimal final processing. This precision minimizes the need for additional machining and painting, thus reducing manufacturing time and costs.

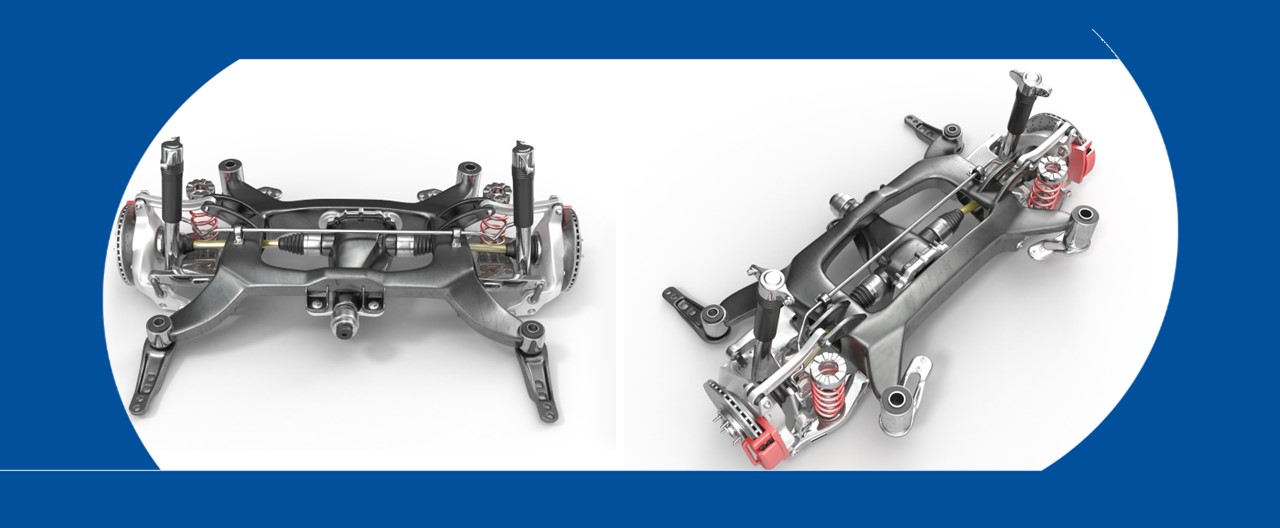

Consider an automotive body component like a radiator support. Traditionally, this might require several smaller parts that need to be assembled or welded together. With die casting, these multiple components can be consolidated into a single, robust piece. This not only streamlines the manufacturing process but also significantly reduces the overall weight of the component.

Material Advantages: Strength Meets Lightness

Die casting alloys offer a unique blend of lightness and strength. On paper, these materials are lighter than steel and only slightly heavier than many plastics. However, die casting alloys boast superior strength compared to nearly all plastic materials. This strength-to-weight ratio allows for thinner cross-sections without compromising on durability.

For example, a door handle designed with die casting technology can achieve superior strength while maintaining, or even reducing, its weight compared to an injection molded counterpart. Properly designed, these components can outperform traditional materials, offering both enhanced strength and weight savings.

Beyond Traditional Assemblies

The true potential of die casting lies in its versatility and application across various automotive parts. From body panels and trim work to seats and even simple components like door handles, die casting can replace traditional assemblies of metal and plastic materials. This not only reduces weight but also simplifies the design and manufacturing process.

When designing die-cast components, it's crucial to consider both the weight and the strength of the material. This holistic approach ensures that the final component or assembly is not only lighter but also performs better.

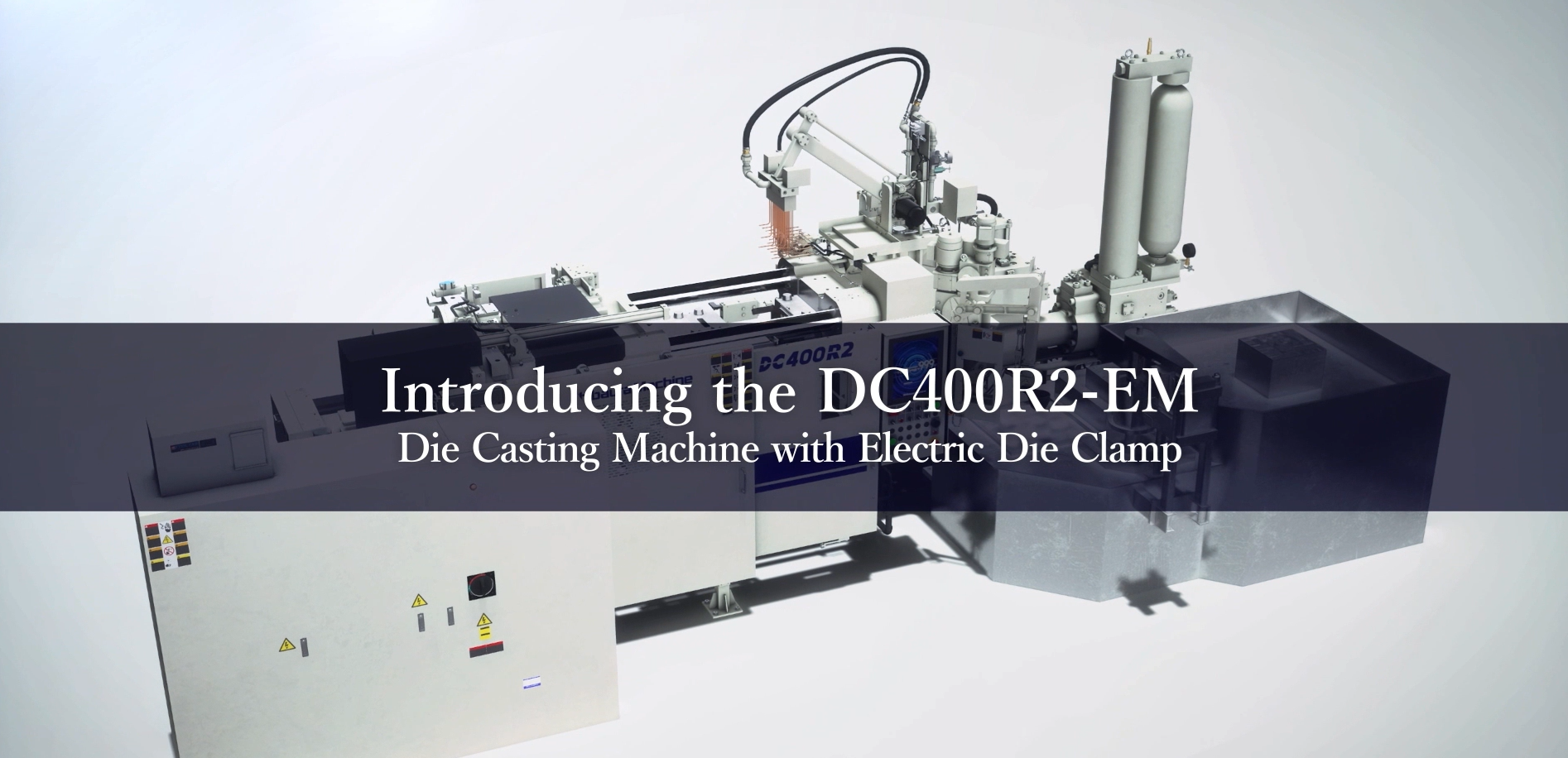

For instance, a seat structure made from a couple of die castings can be lighter and stronger than one made from assembled metal and plastic parts. Shibaura Machine's innovative die casting machines and TOSCAST controller are at the forefront of this advancement, providing unparalleled precision and efficiency in the production of these die cast components.

Embracing the Future of Automotive Design

Weight reduction through die casting represents a significant advancement in automotive design. By leveraging Shibaura Machine's die casting technology, manufacturers can create lighter, stronger, and more cost-effective components. This not only enhances vehicle performance but also contributes to a more sustainable and efficient manufacturing process.

As the automotive industry continues to evolve, the adoption of advanced die casting techniques will be crucial in meeting the demands of modern consumers and regulatory standards. Shibaura Machine stands ready to lead this transformation, committed in the effort towards lighter, more efficient vehicles by providing the machines, technology, and expertise necessary to succeed.

We want to be your service and support partner!

If you have any questions, or require additional assistance, please contact our sales department at:

- Phone: (888) 593-1616

- Email: dc-sales@shibaura-machine.com

Achieving manufacturing excellence has never been easier.

Want to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools